first post here, been lurking awhile.

Took my Dads pre 64 model 70 out yesterday. It hasnt been shot in 30 years probably.

wanted to put some rounds through it and ring some long distance steel.

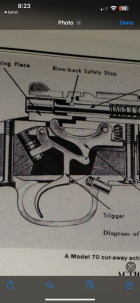

One reason i havent used it is the safety is stuck in FIRE posistion. After some reading i think i know why that is.

I load up 3 rounds and touch off the first round. it goes BANG and shot is well off target.

I go to cycle action and bolt only rotates maybe 20 degrees and stops.

I fiddled with it a little, drop the 2 live rounds out bottom plate, fiddle some more...nada.

Pack up, go home, start searching the web for answers...LOTS about the safety issue, very little about bolt problem.The few hits i did get on bolt ranged from Bubba taking hammer to bolt, to soak in oil and loosen rust.

I took action out of stock, sprayed down with good penetrating oil and cleaned what i could get at, flushed with more oil....nada.

gonna search more, but fear i'm off to a gunsmith.

Any suggestions?

Took my Dads pre 64 model 70 out yesterday. It hasnt been shot in 30 years probably.

wanted to put some rounds through it and ring some long distance steel.

One reason i havent used it is the safety is stuck in FIRE posistion. After some reading i think i know why that is.

I load up 3 rounds and touch off the first round. it goes BANG and shot is well off target.

I go to cycle action and bolt only rotates maybe 20 degrees and stops.

I fiddled with it a little, drop the 2 live rounds out bottom plate, fiddle some more...nada.

Pack up, go home, start searching the web for answers...LOTS about the safety issue, very little about bolt problem.The few hits i did get on bolt ranged from Bubba taking hammer to bolt, to soak in oil and loosen rust.

I took action out of stock, sprayed down with good penetrating oil and cleaned what i could get at, flushed with more oil....nada.

gonna search more, but fear i'm off to a gunsmith.

Any suggestions?

Last edited: