bsl135 said:

Rabbit trail, to Courtney, is a subject that he would rather not be brought to the light of day. This pattern is apparent.

The gentleman who posed the question had previously asserted enough confidence in the experimental method that he said he intended to repeat the experiment himself. His sudden assertion that proper friction measurements were impossible without pressure gauges helped me realize it might not be a short discussion. By the way, ARL didn't use pressure gauges either in their friction studies.

bsl135 said:

So wasting a small amount of taxpayer money is better than wasting more taxpayer money?

We solved an important problem for under $1000. You are welcome to start a new thread if you want to discuss the details, but you seem to prefer jumping to the assertion that our papers were in error. Publish a reply in the scholarly literature if you can document real scientific problems with the work. All you've done so far is complain about who paid for it.

Courtney: The chronographs are calibrated at the site so that their determination of velocity is accurate to within 0.1%, which is a random rather than a systematic error so that uncertainties in the mean values decrease with more data points. We usually shoot 10 bullets each over a range of velocities for each bullet tested, reducing the uncertainties by about a factor of three compared with a single shot. Uncertainties are dominated by shot to shot variations in the bullets themselves or how they leave the rifle.

bsl135 said:

Here's a brainwave for you. What if the optical planes of the chronographs aren't parallel (as I've found the CED's)? You calibrate the chronographs in tandem and apply the offset.

We ensure that the optical planes are parallel and then add mechanical rigidity so that the planes remain parallel. This occurs prior to calibration.

bsl135 said:

That offset only applies for the particular window you shot thru. What about when the bullets pass thru different parts of the screens? I've worked with CED's extensively and found their optical planes to be highly non-parallel. None of your publications addresses this source of error.

As noted above, adding the mechanical rigidity keeps the planes parallel. The window we shoot through at 50 yards is pretty small, about 1". It's not hard to keep varmint bullets in a small window at 50 yards. At larger ranges the window is bigger, and obviously less accurate bullets won't be in a 1" window at 100 and 200 yards. But bullets spread through the window of the far chronograph still provide good readings due to our efforts to keep the planes parallel. These are minutia that we have not mentioned in publications. Perhaps we should have, but editors and peer reviewers have often complained about our method sections being too long with minutia. Method details beyond those in the text have always been immediately clarified for US parties contacting us via email.

Courtney: Also note that the only papers where we rely on 50 yard BC measurements are the papers studying stability and damping of pitch and yaw. When you are using BC to study stability or damping of pitch and yaw, a 50 yard chronograph spacing is more sensitive to the effects you are trying to see.

bsl135 said:

So if the only means to measure something is inaccurate, then... OK?

We've verified the accuracy of the method many ways. You yourself said 50 yard BC measurements were suitable for varmint bullets.

The accuracy of the 50 yard spacing is also double checked with a standard bullet that we have measured the BC of many, many times before. It comes up to within 0.5% of the same number every time.

bsl135 said:

And did this standard bullet pass thru the same portion of the chrono window as the other bullets?

The window issue is much less important given that we ensured that the planes were parallel and added mechanical rigidity. And all the bullets pass through an area less than 5% of the total window.

Courtney: All of our papers comparing original BC measurements with manufacturer specifications have used spacings more like 100-200 yards.

bsl135 said:

but any "useful" BC is measured over more than 200 yards.

Perhaps for shooting at 1000 yards, but not for understanding wind drift in 200 yard benchrest, predicting drops at 600, predicting wind drift at 600, comparing with data from different sources over similar velocity ranges, studying bullet stability, etc.

Sierra measured most of their BCs at ranges 200 yards and less, and many have found their BCs useful over the years. Would you call their data useless? Hornady measures most of their BCs at ranges of 200 yards and less. Would you call their data useless? Most of their AMAX and VMAX BCs are very close to your measurements.

bsl135 said:

And here's "the rest of the story".

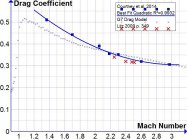

Your low Mach number points were fired from reduced charges in standard twist barrels which does not produce the same RPM or stability condition as a bullet fired at standard MV and slowing at long range.

According to the JBM stability calculator, the lowest Sg represented in that figure is 1.607 under the firing conditions. I thought your view was that BCs did not experience significant drag issues for stabilities above 1.5. Were you assuming the bullet had a stability under 1.5, or do bullets have BC reductions for higher stability?

Our method for determining drag curves is basically the same as Sierra has used for many years. Pick a twist rate that ensures a well stabilized bullet over the velocity range. Fire 10 bullets at a number of velocities using reduced powder charges. Use the velocity drop determined from suitably accurate chronographs over a carefully measured distance, along with carefully measured environmental conditions, to compute the BC.