AlNyhus

Silver $$ Contributor

When you don't see rifling marks...you're not touching. When you do...you are.Operative thought.....Touch is a reference point, that's all. Don't try to make it be something it isn't, that just causes confusion.

When you don't see rifling marks...you're not touching. When you do...you are.Operative thought.....Touch is a reference point, that's all. Don't try to make it be something it isn't, that just causes confusion.

I've always found not removing the barrel to be less work than removing it lol.

Thanks Jim. I intentionally mentioned in my post that there's a place for both methods.It is easier to do it up front before I ever put on another barrel. You may be surprised how many short range guys do it this way. I haven’t found anything faster or simpler and it is repeatable. If I feel the need to check it as the barrel wears that is simple enough using the Wheeler method.

You mis understood. The numbers we would be sharing are in relation to the lands. If I said to load .006 in we would both be .006 in from the same touch point. You can never share comparator numbers even if the same brand.Great method and I love Alex’s worth. The only issue I have with the video is his very last statement where he says that if you use this method, two people could share the numbers and know they are talking about the same dimension. This would only be true if they were using the exact same comparator and caliper setup (not the same brand, the EXACT SAME COMPARATOR ABD CALIPERS)

Dave

You don't have to. Why would you bother even asking such a question? I know but prefer you say it out loud.Why would I want to jump thru hoops and remove a barrel to check how much my lands moved, that just makes no sense to me.

Nah, you can do better if you're being honest. Nice dodge though. Always best to be forthright imho.lemme try.....thread title "Wheeler method" is all I got

Hey Dave, how do you like that gauge? I have a whidden bullet comparator and shoulder bump gauge. The shoulder bump is a great little gauge but the bullet comparator seems to stick to the bullet really easy. Even with minimal effort I get it to the point where I can't even spin a loaded round when it's in the gauge with very minimal pressure.Measuring seating depth.

There is a way so two or more people can measure and compare "like" numbers.

I had to devise a system for an ammo project I had with a customer. I got this idea from a visit with Dave Manson. He used it to measure headspace gages. Think ring gage.

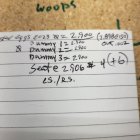

I took neck sizing bushings, all the same size ( supposedly ) and had them surface ground until the edge radius was removed. I used bushing -.002" under nominal bullet diameter. That put the bullet contact point midway up the land in the throat. I used a Whidden multi-purpose OAl gage to hold the bushings. I doubled the number of bushings needed playing CYA. I got I think 75% to read within +/-.001" of each other on the same piece of ammo. We could then talk apples to apples about ammo.

Multi-Purpose Overall Length Gauge - Whidden Gunworks

With the Multi-Purpose Overall Length Gauge attached to your Calipers any standard bushing can be used to measure the length of your loaded round from ogive, fired or unfired case length from Datum line or length of individual bullets from ogive. By simply replacing the bushing the combinations...www.whiddengunworks.com

I perform the operation inside a large plastic bag to contain any flying parts!So here’s a legitimate question for those that strip the bolt at the range or in the shop.

Have you ever lost an ejector pin or spring ? How do you go about preventing such a mishap ?

Thanks

Jim

Check and make sure you get the right type. A plain flat punch works with both types of pins ok, but a roll pin punch is a bit easier for roll pins (obviously, haha) cause it has a balled end that fits inside the pin. I have both types because I didn’t pay attention and got the roll pin punch first.Thanks guys, I’ll order up the pin punch.

Agree 100% Alex. Thanks for clarifyingYou mis understood. The numbers we would be sharing are in relation to the lands. If I said to load .006 in we would both be .006 in from the same touch point. You can never share comparator numbers even if the same brand.

I have that one. It’s perfect. I apologize if I'm just saying things you already know, but even if I am, maybe someone else will find it helpful. Here's the best picture I could get of the two types I have:I ordered this one.

Starrett 1/16" Pin Punch

Excellent quality 1/16" pin punch that we have found to be very durable in the shop. This can be used for installing and removing the pins in kit assembly/disassembly.kiblerslongrifles.com