You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Video of me annealing some brass

- Thread starter JMayo

- Start date

Dusty Stevens

Shiner

2 things- adjust your wheel where the brass runs true. Youre not getting an even flame around the brass. Second is i dont think you have enough time on there. I know you checked it with tempilaq but was there carbon inside? Carbon in the necks throws off the heat transfer and definitely does inside the case. Mine needs at least 5 on the time- verified with a rockwell tester, the pliers test and most importantly the hydraulic press with the datalogger calibration gauge i put on there

Dusty Stevens

Shiner

I don't understand "brass runs true".

They look great and I can't tell old brass (20+ time fired) from new.

Time .. it's based on flame intensity any more runs down too far.

When the flame is on it its severely running out. You adjust the wheel to make it stop in the right spot so it spins true

JMayo

Silver $$ Contributor

Ok, I pulled it out and adjusted. Thanks so much.When the flame is on it its severely running out. You adjust the wheel to make it stop in the right spot so it spins true

I suppose I should do this in the dark so I could get my test cases right to red then back off a midge.

These are sighter brass.

Not “red” but a very “dull red”. You should have to look for it in the light just from the torches.

Watch this to the 2:30 mark. At 2:10 it’s a bit hotter than you want then it cools until the red is just visible. That’s what you want.

Watch this to the 2:30 mark. At 2:10 it’s a bit hotter than you want then it cools until the red is just visible. That’s what you want.

PatMiles

Silver $$ Contributor

beautiful rig. Nice video. I just moved from gas to electric for consistency.

AMP?

Fast14riot

Gold $$ Contributor

Judging temp based on color is crap shoot at best. Look at a low number 1903, HT temp was based on the old timers calibrated eyeballs, however when they started measuring temp they found nearly 300° difference from day to day and action to action from the same old timers.

Tempilaq on the inside of a clean case will get you far closer to actual temp than most eyeballs.

Tempilaq on the inside of a clean case will get you far closer to actual temp than most eyeballs.

I guess a thousand blacksmiths are doing it wrong...

Rather than goop just spring for one of these...

https://www.homedepot.com/p/Milwauk...atives_Non_HDhome-_-205509667-_-206260218-_-N

Rather than goop just spring for one of these...

https://www.homedepot.com/p/Milwauk...atives_Non_HDhome-_-205509667-_-206260218-_-N

Fast14riot

Gold $$ Contributor

As someone who has done blacksmithing, yes they have been doing it wrong. At least for critical components.

Ol’ Ed

“I failed my way to success.” - Thomas Edison

“hydraulic press with the datalogger calibration gauge i put on there” - Dusty, I’ve got a 21st Century hydraulic press coming. Do you mind going into a little more detail on your data logger/pressure sensor (i.e., brands, where acquired, general satisfaction, etc.). Thanks!

Dusty Stevens

Shiner

“hydraulic press with the datalogger calibration gauge i put on there” - Dusty, I’ve got a 21st Century hydraulic press coming. Do you mind going into a little more detail on your data logger/pressure sensor (i.e., brands, where acquired, general satisfaction, etc.). Thanks!

If you want to go down that rabbit hole find your local i&c guy. He will have the test equipment needed. Or you can start here:

https://www.omega.com/en-us/sensors...-strain/pressure-gauges/dpg4000/p/DPG4000-500

jepp2

Gold $$ Contributor

I have a decent infrared temp gun, but for the life of me can't figure a way to use it flame annealing brass. Can't use it when applying the flame, and brass heat transfer is so good, trying to get a reading before the temp is dropping more than enough to give a false reading....Rather than goop just spring for one of these...

Welcome any suggestions for how to get ACCURATE readings.

And that is all after the question about do I stress relieve (750° F) or anneal (1100° F).

jepp2

Gold $$ Contributor

Tempilaq is worthless for temperature measurement if the flame is impinging on it. You are basically measuring the heat of the flame, not the temperature the flame gets the brass to.I'm kinda doing this for the comments.

muleman69

USMC -1st marine Div. RVN

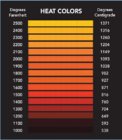

What degree would you say the brass is at this point? Would this be just before the brass starts to sparkle?Not “red” but a very “dull red”. You should have to look for it in the light just from the torches.

Watch this to the 2:30 mark. At 2:10 it’s a bit hotter than you want then it cools until the red is just visible. That’s what you want.

View attachment 1130366 At the point where the red is very dull and almost gone so where in the 1000F to 1100F Range.

A PHD metallugist I used to work with became a consultant to the Cu industry years after he left steel research. He told me that brass begins to turn red at 1050F. I don't know if this is accurate. Don't know his interpretation of beginning red.

Looks like your chart is OK. Don't know if the color changes with different metals (brass VS steel)?

Last edited:

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.