You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thinking of annealing

- Thread starter Jacks Grampa

- Start date

Aim it more on the neck. If you can hold it in your fingers it's not hot enough to anneal. Heat until the neck turns red. Impossible to overheat the body.Any reason this won't work to start? I can clamp the torch to make it safer. Thanks, James

old_heli_logger

Gold $$ Contributor

If you heat it until it is red, then you're likely overdoing it a little...Aim it more on the neck. If you can hold it in your fingers it's not hot enough to anneal. Heat until the neck turns red. Impossible to overheat the body.

Just my opinion.

Good luck

I just can’t convince myself to do it for my amount of shooting. I can see myself causing more problem’s unless I buy that expensive machine, and realistically I might as well spend that money on brass.

It only has to be red for a second. The problem is getting there. You want to get there as fast as possible. Getting there slowly will be a problem for heating the case body and making it too soft.If you heat it until it is red, then you're likely overdoing it a little...

Just my opinion.

Good luck

Anything you do by hand like that is not consistent. Get an amp or skip it all together.

JSH

Gold $$ Contributor

So prior to 90 some percent of shooters not having a mechanical type annealer 10-15 years ago it was a waste of time? There were few annealing machines in the late 80’s and 90’s, then they were out of reach cost wise for majority of shooters. Ken Light machine was the first one I saw. I know of one club that bought the machine, then charged a fee for its use.

Hell when I started annealing we were standing cases in a pan of water, and tipping them over when hot.

Bottom line, annealing will and does extend case life. If the OP was a PRS or LR shooter, the question would probably not been asked.

Hell when I started annealing we were standing cases in a pan of water, and tipping them over when hot.

Bottom line, annealing will and does extend case life. If the OP was a PRS or LR shooter, the question would probably not been asked.

Ccrider

Gold $$ Contributor

Bottom line, annealing will and does extend case life.

Do not disagree with this. I am not concerned with extending case life, but if the op is, let the torches flame!

Shooting small groups requires consistency.

Plenty of real accurate info saying you want the neck red. You can not soften the body at 400-500F even for a couple minutes.If you heat it until it is red, then you're likely overdoing it a little...

Just my opinion.

Good luck

NZ_Fclass

Silver $$ Contributor

I would have thought that since the introduction of the AMP, more flame annealing machines would be available on the 2nd hand market.

But there are some reasonably priced new machines out there -The Ugly annealer, for one, that can work quite well with a bit of calibrating.

But there are some reasonably priced new machines out there -The Ugly annealer, for one, that can work quite well with a bit of calibrating.

Clancy

Silver $$ Contributor

Used bench sources are cheap enough.I just can’t convince myself to do it for my amount of shooting. I can see myself causing more problem’s unless I buy that expensive machine, and realistically I might as well spend that money on brass.

I've posted the results of proper flame annealing enough over the years. It works great.

If you ever have a batch of cases you’re attached to send them to me and I’ll do them for you.

MikeRu

Gold $$ Contributor

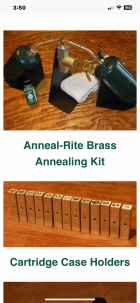

Lots of good opinions above, here’s what I do:

www.cartridgeanneal.com

www.cartridgeanneal.com

Cheap, very consistent bullet seating pressures, and shoots accurately.

Aim at the neck shoulder junction, avoid room air currents, rock back and forth in the flame, use a metronome to heat for 9-10 sec, stop about 1 sec after the 750 Tempilaq melts, drop onto a cotton cloth, perhaps because the time is prolonged any red glow is overcooked in my hands—the neck tension drops off a lot. The goal is consistent neck tension and you can measure this as seating pressure on an arbor press.

If this gives inconsistent results you can always spend more later—good luck.

Brass Annealing Machine | Rifle Brass Annealing | Enterprise Services LLC

Looking for a brass annealing machine? Our professionals can help. Enterprise Services LLC sells top of the line Anneal-Rite brass annealers. Click to learn more!

www.cartridgeanneal.com

www.cartridgeanneal.com

Cheap, very consistent bullet seating pressures, and shoots accurately.

Aim at the neck shoulder junction, avoid room air currents, rock back and forth in the flame, use a metronome to heat for 9-10 sec, stop about 1 sec after the 750 Tempilaq melts, drop onto a cotton cloth, perhaps because the time is prolonged any red glow is overcooked in my hands—the neck tension drops off a lot. The goal is consistent neck tension and you can measure this as seating pressure on an arbor press.

If this gives inconsistent results you can always spend more later—good luck.

Attachments

old_heli_logger

Gold $$ Contributor

Thank you, my neck is red enoughPlenty of real accurate info saying you want the neck red. You can not soften the body at 400-500F even for a couple minutes.

When I calibrate my Annealeez, I do it in a dim room and try to go for a very dull orange. My seating pressure is very consistent, so that works for me

The only problem is . . . 750°F doesn't really get the job done properly.Lots of good opinions above, here’s what I do:

Brass Annealing Machine | Rifle Brass Annealing | Enterprise Services LLC

Looking for a brass annealing machine? Our professionals can help. Enterprise Services LLC sells top of the line Anneal-Rite brass annealers. Click to learn more!www.cartridgeanneal.com

Cheap, very consistent bullet seating pressures, and shoots accurately.

Aim at the neck shoulder junction, avoid room air currents, rock back and forth in the flame, use a metronome to heat for 9-10 sec, stop about 1 sec after the 750 Tempilaq melts, drop onto a cotton cloth, perhaps because the time is prolonged any red glow is overcooked in my hands—the neck tension drops off a lot. The goal is consistent neck tension and you can measure this as seating pressure on an arbor press.

If this gives inconsistent results you can always spend more later—good luck.

Why you'd have inconsistent neck tension when getting that red glow, I have no idea, since I get very consistent neck tension when I do. When I used to use 750°F, my neck tension was pretty consistent within the batch that had just been annealed, but very different tension after a number of annealing sessions at that temperature.

old_heli_logger

Gold $$ Contributor

Do you see any flare ups when your zinc is getting cooked off the tip of the neck?The only problem is . . . 750°F doesn't really get the job done properly.

Why you'd have inconsistent neck tension when getting that red glow, I have no idea, since I get very consistent neck tension when I do. When I used to use 750°F, my neck tension was pretty consistent within the batch that had just been annealed, but very different tension after a number of annealing sessions at that temperature.

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.