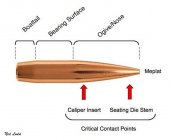

Made and have been using this tool (exploded view) to measure just the tips of the bullets. It contacts at .183” diameter on the ogive, which is the same location that the Hoover trimmer bears. I believe that the newest Hoover trimmer bodies can also be used much like this tool. The dial indicator may need a longer than normal stem though.

By measuring only the tip, any other bullet dimensional variations are irrelevant. It makes it easy to determine exactly how much to trim the bullets to get a 100% cut on the circumference of each bullet. It is also surprising how often the bullets are not trimmed to a consistent tip measurement, due to not letting the cutter “dwell” for a moment. A thrust bearing between the trimmer body and the cutter stop collar helps a bunch. Without taking this measurement, one would never know that this error existed.

If pointing bullets, it is also useful to know how much the bullet tip is growing, due to the pointing. Yes, one can determine that same thing by measuring a given bullet before and after pointing, but it can vary somewhat by any tolerances in the sorting and by not chasing the overall length with the pointing die setting.

I also made inserts and a custom indicator tip to measure the actual length of the ogive, from the .183” contact point to just above the major diameter of whatever caliber is being measured.

Does any of this really matter? Been done before? Just food for thought, and your mileage may vary.

By measuring only the tip, any other bullet dimensional variations are irrelevant. It makes it easy to determine exactly how much to trim the bullets to get a 100% cut on the circumference of each bullet. It is also surprising how often the bullets are not trimmed to a consistent tip measurement, due to not letting the cutter “dwell” for a moment. A thrust bearing between the trimmer body and the cutter stop collar helps a bunch. Without taking this measurement, one would never know that this error existed.

If pointing bullets, it is also useful to know how much the bullet tip is growing, due to the pointing. Yes, one can determine that same thing by measuring a given bullet before and after pointing, but it can vary somewhat by any tolerances in the sorting and by not chasing the overall length with the pointing die setting.

I also made inserts and a custom indicator tip to measure the actual length of the ogive, from the .183” contact point to just above the major diameter of whatever caliber is being measured.

Does any of this really matter? Been done before? Just food for thought, and your mileage may vary.