I was at the range today after a lousy day hunting ghogs yesterday. I missed three in a row, 262, 237, and 145. The first two I can blame on the wind, 20 to 30 mph cross winds swirling. Even with the wind, the last miss at 145 yards baffled me. I did connect with one at 147 yards in early evening after the wind subsided. Thus the reason for the range session today. Rifle fine - shooter not.

Anyway, getting to the point of this thread, a fellow was shooting a 300 Black Out Rem factory bolt rifle next to me. Shooting some really nice groups. He went to eject a spent case and the case was frozen into the bolt face. He asked me my opinion as to what went wrong. So I ran down a list of questions to him then examined the rifle and bolt.

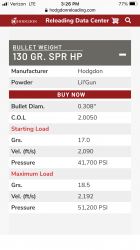

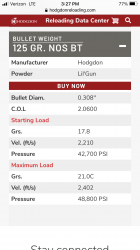

The shot was not erratic, i.e. within the group of the other shots. There were no signs of pressure that I could determine i.e. he said he did not experience any hard bolt lift. There was no evidence of case head separation or cracks in the case. He stated that the powder charge was grain and half below maximum. A ball powder, Hodgdon brand used per published data. He stated that with this powder, it's impossible to double charge. I can't remember the name of the powder he told me. But he had been using it, same lot for some time with no problems.

He told me that he experienced some gas blow back during the shot but he was not injured - was wearing glasses. Case were loaded 6 previous times and bullet was a Hornady 125 grain SST seated at the cannelure, well back from the lands. Primers were Winchester. Guy has been loading for 30+ years - seemed very knowledgeable.

The bolt was a standard Rem 700 type bolt. I could see no damage to the bolt except the case seem to be "welded" into the bolt face. I was able to partially disengage the firing pin assembly from the bolt shroud but could not remove it. It wouldn't fully unscrew and was also frozen in the bolt shroud. Even with some force applied to the case it would not dislodge from the bolt face. I gave him the name of my rifle smith and told him to have him examine it.

The only thing I could figure was that somehow the primer failed and leaked gas back to the bolt face and 'welded" the case to the bolt face. Is that possible? I've never seen anything like this before. What do you guys think happened?

Anyway, getting to the point of this thread, a fellow was shooting a 300 Black Out Rem factory bolt rifle next to me. Shooting some really nice groups. He went to eject a spent case and the case was frozen into the bolt face. He asked me my opinion as to what went wrong. So I ran down a list of questions to him then examined the rifle and bolt.

The shot was not erratic, i.e. within the group of the other shots. There were no signs of pressure that I could determine i.e. he said he did not experience any hard bolt lift. There was no evidence of case head separation or cracks in the case. He stated that the powder charge was grain and half below maximum. A ball powder, Hodgdon brand used per published data. He stated that with this powder, it's impossible to double charge. I can't remember the name of the powder he told me. But he had been using it, same lot for some time with no problems.

He told me that he experienced some gas blow back during the shot but he was not injured - was wearing glasses. Case were loaded 6 previous times and bullet was a Hornady 125 grain SST seated at the cannelure, well back from the lands. Primers were Winchester. Guy has been loading for 30+ years - seemed very knowledgeable.

The bolt was a standard Rem 700 type bolt. I could see no damage to the bolt except the case seem to be "welded" into the bolt face. I was able to partially disengage the firing pin assembly from the bolt shroud but could not remove it. It wouldn't fully unscrew and was also frozen in the bolt shroud. Even with some force applied to the case it would not dislodge from the bolt face. I gave him the name of my rifle smith and told him to have him examine it.

The only thing I could figure was that somehow the primer failed and leaked gas back to the bolt face and 'welded" the case to the bolt face. Is that possible? I've never seen anything like this before. What do you guys think happened?