Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

suitable steel for resizing die

- Thread starter liseo

- Start date

I would use a free-machining mild steel and case harden it. WH

Seems in the expensive side. And I´m outside USANewlon sells their dies in 416 and 12L-14. Either should be nitrided imo

WillI would use a free-machining mild steel and case harden it. WH

case hardening did not cause changes in dimensions?

paperpuncher

Gold $$ Contributor

What about 1144 stressproof? Asking for a freind

Do you have any experience nitriding 416 ss for dies. I don't is why I'm asking. Just curious as to your thoughts on it. My understanding is it'd be very similar to case hardening them. Doesn't have to be 416. I just mention it because I have a bucket of cutoffs. Something like 12l-14 or what do you prefer?I would use a free-machining mild steel and case harden it. WH

LVLAaron

Gold $$ Contributor

Seems in the expensive side. And I´m outside USA

Will

case hardening did not cause changes in dimensions?

I'm just suggesting that they know what they're doing, and those are the metals they use.

I would think 4140 would be hell on a reamer.

416 and nitride should make a nice die and won't kill the reamer.

1144 machines and hardens beautifully.

12L44 even more so.

12L44 even more so.

jackieschmidt

Gold $$ Contributor

I have cut passed the case Hardenning on several “factory” dies, and I believe they are made from 12L14 or some other leaded free machining steel.

If you think there is anything true about the various factory dies, they obviously do experience some warpage during the case hardening process. Just chuck one up and watch the needle jump around as you try to true it Up.

Does it matter. No.

As for 1144 StressProof, It is a resulphurized steel that machines beautifully. We use it a lot at my Shop. But, the heavy sulphur content makes it a poor choice for case Hardenning as cracks can occur at the molecular level. In short, it is designed to be used as is, which of course is not hard enough for a die.

There are simply better options.

If you think there is anything true about the various factory dies, they obviously do experience some warpage during the case hardening process. Just chuck one up and watch the needle jump around as you try to true it Up.

Does it matter. No.

As for 1144 StressProof, It is a resulphurized steel that machines beautifully. We use it a lot at my Shop. But, the heavy sulphur content makes it a poor choice for case Hardenning as cracks can occur at the molecular level. In short, it is designed to be used as is, which of course is not hard enough for a die.

There are simply better options.

Last edited:

I have never tried making a die from stainless and nitriding it. Mild steel, case hardened, stayed pretty close dimensionally. The depth of the case depended on how long you carburized the piece. I used stainless for bushing dies and collet dies.

Regarding nitriding. I first had a bolt nitrided in the late nineties and felt that it did smooth up the action (a Model 70 , as I recall).This was one of those actions which was sticky. This happens when the bolt and receiver are the same material and neither one very hard.

About this time, I was making air cylinders and having the barrel hard chromed, for wear resistance and corrosion prevention. I tried having some nitrided instead, and it worked out pretty well.

I case hardened a lot of bushings for heavy equipment. I got the Idea of coating the inside with moly before packing it in the charcoal for carburizing. It worked surprisingly well and gave me a hard, slick surface. I have always intended to try it on a die but never have. WH

Regarding nitriding. I first had a bolt nitrided in the late nineties and felt that it did smooth up the action (a Model 70 , as I recall).This was one of those actions which was sticky. This happens when the bolt and receiver are the same material and neither one very hard.

About this time, I was making air cylinders and having the barrel hard chromed, for wear resistance and corrosion prevention. I tried having some nitrided instead, and it worked out pretty well.

I case hardened a lot of bushings for heavy equipment. I got the Idea of coating the inside with moly before packing it in the charcoal for carburizing. It worked surprisingly well and gave me a hard, slick surface. I have always intended to try it on a die but never have. WH

Alex Wheeler

Site $$ Sponsor

Nitrided 416 works very well. And less likely to crack than hardened dies. So I prefer it for some of this really tough brass we use.

AlexNitrided 416 works very well. And less likely to crack than hardened dies. So I prefer it for some of this really tough brass we use.

The barrel steel (416R) will work the same as 416?

If so, this is good, as I have a way to do the nitride thing

Thank you to everyone who contributed with their suggestions and experiences

DaveTooley

Gold $$ Contributor

I've made a lot of FL dies out of 12L14 and had them case hardened. All made to very tight tolerances with no problems. That was prior to nitridng coming into the picture. If I was to do it again I would use 416 and have them nitrided. Be careful about finish reamer dimensions in relation to the resize reamer.

mike mccormick

Silver $$ Contributor

What about S7 ?? I know they make a lot of punch press dies from it.

DRK

Silver $$ Contributor

I think any tool steel would work if you have it laying around. 01, D2, A2, S7. A2 is probably cheapest per lb if you have to buy it.

S7 does well for punches to handle the shock of breaking through a sheet, plate, coil, etc. For a draw die I don't think it matters much.

S7 does well for punches to handle the shock of breaking through a sheet, plate, coil, etc. For a draw die I don't think it matters much.

I've made a lot of FL dies out of 12L14 and had them case hardened. All made to very tight tolerances with no problems. That was prior to nitridng coming into the picture. If I was to do it again I would use 416 and have them nitrided. Be careful about finish reamer dimensions in relation to the resize reamer.

Dave

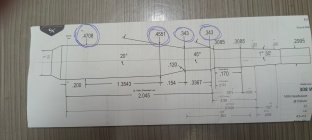

If you don't mind, what measurements would you take on this resizer if you want to work the case as little as possible and leave the neck diameter at .3350"/.3355"(before expander).

Consider annealing cases after every reload

Attachments

Similar threads

- Replies

- 5

- Views

- 1,781

- Replies

- 12

- Views

- 1,283

- Replies

- 1

- Views

- 1,352

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.