It could be that way, as it could also be that the press piston/shellholder and the die are not alignedcould that possibly be your bolt raising up/tilting slightly when cocked?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Still doubts about shoulder bump...

- Thread starter Bora72

- Start date

the paint on the head comes off but in a limited areaPut it back in the rifle and while pushing the bolt forward run the handle up and down a few times. Then what do you have?

We don't disagree on that. I wasn't implying you don't determine the amount of setback on the case by firing and resizing. You can't assume that the case measurement is the chamber dimension. Even after several firing the case will not grow to match the chamber dimension but it will be close. The issue comes when trying to decide what may be causing resistance to the bolt closing.I disagree with your first couple of sentences.

Actually measuring before the case is sized and afterward is the only way to know exactly how much you are sizing the case.

With any other method, you are guessing.

Ccrider

Gold $$ Contributor

Not necessarily true. Dependson how hot the loads are.Even after several firing the case will not grow to match the chamber dimension but it will be close.

DaveTooley

Gold $$ Contributor

you're worrying about something thatLook at some paint below the extractor

1. is completely out of your control

2. It affects nothing other than your mind

Give us your details on how you anneal.Oh, I forgot, I anneal the necks after every shot.

Why?you're worrying about something that

1. is completely out of your control

2. It affects nothing other than your mind

Soon as possibleGive us your details on how you anneal.

I noticed something odd when I resized the cases to 1.485" (+ or - .0005"), but I had good consistency according to what you explained.

However, when I raise the ram and the case begins to engage the die, the case head pops up on one side and separates from the shellholder.

It seems as if the press ram and the die are not aligned on the same vertical axis.

Do you have any suggestions or tests I can perform to verify this?

However, when I raise the ram and the case begins to engage the die, the case head pops up on one side and separates from the shellholder.

It seems as if the press ram and the die are not aligned on the same vertical axis.

Do you have any suggestions or tests I can perform to verify this?

Attachments

Coyotefurharvester

Silver $$ Contributor

Your observation could be the expander/decapper assembly is not centered in the mouth of the die or case(rod bent/loose?). Make sure the shell holder is clean/free of lube.

Looks like you did a great job. What temp do you think the necks are reaching. I don't see a color change in the video?This is my annealer, hand made by myself.

Your observation could be the expander/decapper assembly is not centered in the mouth of the die or case(rod bent/loose?). Make sure the shell holder is clean/free of lube.

The shell holder are free of lube and debris.

I removed the decapping unit, I use a separate expander die.

Looks like you did a great job. What temp do you think the necks are reaching. I don't see a color change in the video?

Thanks.

I think 750/800ºF.

The color change, look

Case heads are not always squareLook at some paint below the extractor

also over time, they get pounded off square if they started out square

(the bolt slop allows very slight rise in the trigger area so the bolt is no longer square to the raceway)

I recently shaved .002" off the head on 10 cases to square them up to see if it affects anything

Have not tested them yet

and I expect to see nothing different,

the gun shoots in the .2's' or better now

if it holds in the .1's then I may attribute it to squred case heads

if I see no improvement, then I will not worry about square case heads

---

Your case heads are likely not perfectly perpendicular to the chamber centerline

is what you may be seeing

---

to conduct the sharpie marker test you are doing now, you need to ensure your case heads are perpendicular and perfectly flat to begin with

Case heads are not always square

also over time, they get pounded off square if they started out square

(the bolt slop allows very slight rise in the trigger area so the bolt is no longer square to the raceway)

I recently shaved .002" off the head on 10 cases to square them up to see if it affects anything

Have not tested them yet

and I expect to see nothing different,

the gun shoots in the .2's' or better now

if it holds in the .1's then I may attribute it to squred case heads

if I see no improvement, then I will not worry about square case heads

---

Your case heads are likely not perfectly perpendicular to the chamber centerline

is what you may be seeing

---

to conduct the sharpie marker test you are doing now, you need to ensure your case heads are perpendicular and perfectly flat to begin with

Ok, you made yourself clear, for now I don't have to worry, especially with a mass-produced rifle.

This is the accuracy my rifle allows me (beginner

Attachments

That's phenomenal! is that a 4 or 5 shot group there?Ok, you made yourself clear, for now I don't have to worry, especially with a mass-produced rifle.

This is the accuracy my rifle allows me (beginner), 35.3gn RS50, 139 Scenar, OAL 71mm (2.795"), Harris bipo, tactical rear bag, 100m (109yd):

The fact you are using a bipod also shows your technique for holding the rifle, pressure etc is very good.

Since bipod discipline can be something that takes awhile to learn to get the gun to react the same every time

You cannot anneal at 750/800F. you may be stress relieving. You need to be at about 1050/1100F to anneal. The neck should just turn red for 1-2 seconds.Thanks.

I think 750/800ºF.

The color change, look

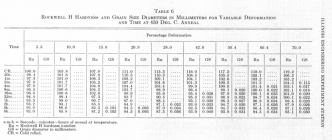

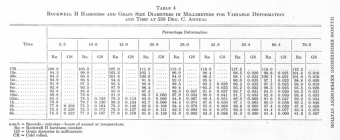

When I look at the charts I compare 15% cold work reduction in thickness to the several temperatures. It seems like a good guess at % cold work since we don't know the actual %. The trends are what I look at rather than the actual numbers. The next chart in the report was 600C=1112F this is much higher than I want. The shortest time in the study was 15 seconds at temp in a lead bath. The sample had thermal couples on them and time was time at temp

What I see is practically nothing happens at 15 seconds at temp at temp in a lead bath.

There are many scales for reporting hardness this study used the Rockwell H scale. The cold work was achieved by cold rolling a small plate about 1/8" thickness to various thicknesses. Don't jump on they are not cartridges. The numbers basically give you an idea of what's going on.

Results:

15% cold work 30 seconds at 842f showed a .8 RH increase. 10% cold rolled showed 2 unit decrease. Probably within the error because they are different pieces of metal even though they were processed under similar conditions.

4 hr at temp before grain size changes with 15% CR.

450C=842F

550C=1022F

Below are the results of my annealing study done at work on cartridge necks annealed in a small laboratory accurate furnace. I chose 15 sec hold time in the furnace since I didn't know how long it took the neck to reach temp. 5 minutes at 800F the hardness only dropped about 2 units HRB sale.

Attachments

Last edited:

Similar threads

- Replies

- 22

- Views

- 6,379

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.