Hey guy just wanted an opinion on this indicator, it has a deep hole attachment that 1.625 I believe. Could this be used to accurately dial in a bore for either chambering or muzzle work? I know it’s only 0.001 indicator but as long as the needle doesn’t move or move much I think it would be fine. I’m not new to machining, but I am new to barrel work. So, I don’t know if this is will go deep enough to be sufficient. I cannot afford an Intrepid long stem it’s just too much for me right now. I have limited funds but want to practice now and not have to wait a year till I save up for a 400.00 intrepid. Even a Browne and Sharp is too much. I found this starrett for a good deal and thought about trying it but wanted to run it past the experts first. I know a lot of guys do barrel work between centers and I’m sure they are not 100% perfect and most use floating reamer holders. But they still shoot darn good groups. I am trying to be realistic for real world conditions be it machine wear, temperature and other variables. Holding a 0.0001 tolerance on barrel work in a home shop sounds like a long shot from my machining background. That’s why we were always given tolerances, and when guys including me got job that were +- nothing we ignored it because it’s almost impossible even with cnc machines, at least with the machines we had. Most common was a + or - 0.001 or 0.002. Occasionally one would come through with a 0.0005 +- and you had to check every part and keep a close eye on tool wear and adjust offsets accordingly throughout the day.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starrett 196A1z For Barrel Work

- Thread starter Shooting in the wind...

- Start date

jackieschmidt

Gold $$ Contributor

Those particular indicators have been around for years. They are a good utility indicator for general shop use. Just don’t ever drop one. They have a pin and scroll mechanism that will shear from shock if you drop it and it hands on the button.

you are correct in assuming that the “ wiggler” will allow you to reach in quite a ways into the barrels bore. Just keep the little points that it pivots on snug enough so there is minimum side play.

The. resolution is .001, But these indicators have a tendency to stick, so double check your work.

As for tolerances, you can only indicate a piece in to the accuracy of your head stock bearings. Realistically, shoot for .0005. For years, I did my own barrel work on our Shops Pratt &Whiney Tool Room Lathe. I could indicate throats in to .0001 with no worries.

I now do my barrels in a little 13 inch TurnPro at my house, and while it is a pretty good,title lathe, it simply will not hold that. typically .0003 is as close as I can get anything.

But the barrels shoot just as well.

you are correct in assuming that the “ wiggler” will allow you to reach in quite a ways into the barrels bore. Just keep the little points that it pivots on snug enough so there is minimum side play.

The. resolution is .001, But these indicators have a tendency to stick, so double check your work.

As for tolerances, you can only indicate a piece in to the accuracy of your head stock bearings. Realistically, shoot for .0005. For years, I did my own barrel work on our Shops Pratt &Whiney Tool Room Lathe. I could indicate throats in to .0001 with no worries.

I now do my barrels in a little 13 inch TurnPro at my house, and while it is a pretty good,title lathe, it simply will not hold that. typically .0003 is as close as I can get anything.

But the barrels shoot just as well.

Last edited:

hpshooter

Gold $$ Contributor

Kind of related. I lent a brand new one to an "experienced" fellow. If you know these indicators they were shipped with a plastic collar on the button stem to prevent blunt force trauma to the internal mechanism. The borrower returned the indicator and told me it was broken, he had pushed on the button until the "little plastic thing" popped off the stem and the dial went full scale and wouldn't return to zero." But these indicators have a tendency to stick, so double check your work."

Lesson repeated for me! Be careful who you lend stuff to. Applies to everything from 2 ounce triggers to anvils.

When I worked at the GM Training Center 25 years ago I had about six of the same dial indicator set. I thought they were great dial indicators but they were fragile. One of them broke as described above and another, the needle broke off. Both as a result of being dropped by students. We had a guy in the plant who fixed them. Probably would be difficult to get one repaired today.

xr650rRider

Silver $$ Contributor

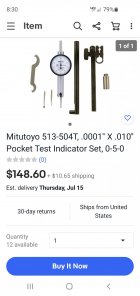

A Mitutoyo 513-504 with this contact tip installed would be a lot better. Not as nice as the Interapid 312B-15 but I use it with short tip as .0001" indicator a lot. When you put the long tip on, it's closer to a .0007" indicator. Still works pretty decent.

butchlambert

Site $$ Sponsor

A Mitutoyo 513-504 with this contact tip installed would be a lot better. Not as nice as the Interapid 312B-15 but I use it with short tip as .0001" indicator a lot. When you put the long tip on, it's closer to a .0007" indicator. Still works pretty decent.

I have both, but prefer the Mitutoyo.

jackieschmidt

Gold $$ Contributor

I use the 504-513.

JoeMcNeill

Silver $$ Contributor

I have one of those Starret 196A sets, NIB, from years ago when we used them to rebuild centrifugal compressors for AC/refrigeration for York International. Always kept a couple sets in case someone borrowed one or it got dropped. Had a few taken away at an airport once because indicators in inches were not allowed in a metric country!!! If anyone is interested in a set you can PM me because I will never use it.

JDM

SW Arkansas

JDM

SW Arkansas

rickhirsch

Silver $$ Contributor

hey guys they work but if want the best you buy interapid indicator . i was a machinist for 45 years

still work on guns. i've had almost all of then. grinders like brown'en sharp .mill guys like the interapid

lathe guys like midutoyo . interapid hold up. i have some that are 40 years old . love starret mic's .

don't like starret indicator's. and i've had a few of them .they don't hold up .near as well as interapid.

starret calibers aren't that good either . that being said half my tools are starret. hope this helps you guys.

just a old machinist point of view.

still work on guns. i've had almost all of then. grinders like brown'en sharp .mill guys like the interapid

lathe guys like midutoyo . interapid hold up. i have some that are 40 years old . love starret mic's .

don't like starret indicator's. and i've had a few of them .they don't hold up .near as well as interapid.

starret calibers aren't that good either . that being said half my tools are starret. hope this helps you guys.

just a old machinist point of view.

butchlambert

Site $$ Sponsor

Yes, Us old fuggers are strong in our opinions.hey guys they work but if want the best you buy interapid indicator . i was a machinist for 45 years

still work on guns. i've had almost all of then. grinders like brown'en sharp .mill guys like the interapid

lathe guys like midutoyo . interapid hold up. i have some that are 40 years old . love starret mic's .

don't like starret indicator's. and i've had a few of them .they don't hold up .near as well as interapid.

starret calibers aren't that good either . that being said half my tools are starret. hope this helps you guys.

just a old machinist point of view.

I was just looking for an affordable way to do my first one without needing to spend 400.00 just yet. I do plan on getting one just not at the moment. I would try between centers but my lead screw is 12” short because of a previous owners “repair” and my tail stock sits 0.004 low 12” away from the chuck. I know you can shim up the tail stock but that isn’t gunna help till I get my lead screw fixed hense why I just wanted to do it through the headstock. I have a mill too and just figured that the starrett 196a1z may do the trick for now and could also pull double duty if need be.

DaveTooley

Gold $$ Contributor

Many do a second op dialing in the bore after they rough out the chamber.I was just looking for an affordable way to do my first one without needing to spend 400.00 just yet. I do plan on getting one just not at the moment. I would try between centers but my lead screw is 12” short because of a previous owners “repair” and my tail stock sits 0.004 low 12” away from the chuck. I know you can shim up the tail stock but that isn’t gunna help till I get my lead screw fixed hense why I just wanted to do it through the headstock. I have a mill too and just figured that the starrett 196a1z may do the trick for now and could also pull double duty if need be.

Similar threads

- Replies

- 0

- Views

- 299

- Replies

- 5

- Views

- 487

- Replies

- 27

- Views

- 1,471

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.