300 RUM

Gene Nowaczyk

Well I have 5 pieces of loaded ammo that some one has sent to me for an analysis The ammo was the kind that had the said "popping noise" when resetting a bullet. I won't say there names I'll keep that secret unless they want to disclose themselves. But everyone should give a big hand to that person, I have been asking for the problem ammo to be sent to me for over a year now.

Ok down to business, I just received the ammo so not all testing is complete yet, but I had to start looking for a cause, it is very exciting. I have enclosed some photos not the best but they do show signs of what is going on and I will explain some of it but not all. If you want to know more you will have to pm your number to me and I will call you and chat a bit if you want.

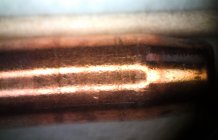

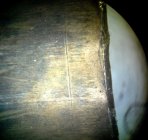

First the brass was in normal condition and the bullet also . The first issues found was some embedded copper jacket into the brass that had torn from the bullet and stuck to the brass cartridge, they ranged in size from 15 micron to 30 micron and obviously freshly torn. The second issued found are a couple of cylindrical rings protruding from the brass and a depression into the softer copper bullet jacket. Other items found were some carbon deposits and some sort of crystallization of a unknown product at this time. Last but not lest the base of the bullet (boat tail to be exact) had oxidation on it, mostly caused by the chemicals found in the powder. Now most powders have additives to prevent oxidation from occurring how ever does not eliminate the possibility. Also double based propellants have NITROGLYCERIN in them, and contain ingredients that range from slight to strong oxidizing properties.

The small particles of copper jacket were removed from the brass and examined for any kind of fusion, the so called "cold fusion", NONE WERE FOUND. The brass and copper were simply latched together with very small protrusions in the brass embedding themselves into the softer copper jacket creating a "Shear effect" when resetting the bullet. It would be correct to say that over time as the brass contracts back to it's original state after sizing a mechanical bond becomes more prevalent.

Currently I have several thoughts on this matter. 1st, unless the bullet and brass are polished to a perfect less then 5 micron surface one may never be able to prevent this occurrence from happening. 2nd the act of polishing the necks with a copper or brass brush after sizing just before bullet seating may reduce the effect but not alive it.

Ok down to business, I just received the ammo so not all testing is complete yet, but I had to start looking for a cause, it is very exciting. I have enclosed some photos not the best but they do show signs of what is going on and I will explain some of it but not all. If you want to know more you will have to pm your number to me and I will call you and chat a bit if you want.

First the brass was in normal condition and the bullet also . The first issues found was some embedded copper jacket into the brass that had torn from the bullet and stuck to the brass cartridge, they ranged in size from 15 micron to 30 micron and obviously freshly torn. The second issued found are a couple of cylindrical rings protruding from the brass and a depression into the softer copper bullet jacket. Other items found were some carbon deposits and some sort of crystallization of a unknown product at this time. Last but not lest the base of the bullet (boat tail to be exact) had oxidation on it, mostly caused by the chemicals found in the powder. Now most powders have additives to prevent oxidation from occurring how ever does not eliminate the possibility. Also double based propellants have NITROGLYCERIN in them, and contain ingredients that range from slight to strong oxidizing properties.

The small particles of copper jacket were removed from the brass and examined for any kind of fusion, the so called "cold fusion", NONE WERE FOUND. The brass and copper were simply latched together with very small protrusions in the brass embedding themselves into the softer copper jacket creating a "Shear effect" when resetting the bullet. It would be correct to say that over time as the brass contracts back to it's original state after sizing a mechanical bond becomes more prevalent.

Currently I have several thoughts on this matter. 1st, unless the bullet and brass are polished to a perfect less then 5 micron surface one may never be able to prevent this occurrence from happening. 2nd the act of polishing the necks with a copper or brass brush after sizing just before bullet seating may reduce the effect but not alive it.