Working on some Winchester brass in 270 Win for my son’s Ruger American. Trim to length is posted as 2.53” in each of the 2 manuals I own, and I’ve always needed to trim this Winchester brass (.007” max) after FL sizing. I just received a Sinclair chamber length gauge and have measured the chamber on this gun at 2.581”. Resized cases have measured as much as 2.537” after each of 3 firings. My question is, should I continue to trim this brass so it’s all the same length? I’ve read that ideally brass would measure chamber length minus .010”...is it likely my cases would stretch .040” if I stopped trimming? Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sinclair chamber length gauge...

- Thread starter Jody Simcox

- Start date

Depends to a degree on how you resize and the dimensions of the die compared to the chamber.

Neck sizing possibly not, whereas a FLS die on the 'tight' side may result in longer cases as more brass is squeezed down in the process and it has to go somewhere, so this can make the case longer. I trim 0.308 cases every time to 2.010, which is 0.015 shorter than the 2.025 chamber length as measured by the Sinclair gauge.

Depending on your shooting needs there's always the custom die option, amongst other things this will minimise the amount that the brass is resized thus minimising case 'stretch'.

For LR accuracy, I would always trim cases to the same length for consistency and to reduce a potential variable and I use a custom die.

Martin

Neck sizing possibly not, whereas a FLS die on the 'tight' side may result in longer cases as more brass is squeezed down in the process and it has to go somewhere, so this can make the case longer. I trim 0.308 cases every time to 2.010, which is 0.015 shorter than the 2.025 chamber length as measured by the Sinclair gauge.

Depending on your shooting needs there's always the custom die option, amongst other things this will minimise the amount that the brass is resized thus minimising case 'stretch'.

For LR accuracy, I would always trim cases to the same length for consistency and to reduce a potential variable and I use a custom die.

Martin

I'm in the same boat with 2 223's of the same brand. I plan to let my sized brass grow for about three firings , and trim as long as I can to uniform. These are 0.25- 0.30 longer than recommended trim length. I also measured a few rifles of a different brand and they were both much closer to spec . Perhaps .005 longer, so those will be trimmed as usual.

the chamber on this gun at 2.581”.

Interesting. I would like to know the diameter of the Sinclair chamber length gauge. .278" or .308"? Just asking.

https://saami.org

Anyone should consider the credibility of 'recommended trim length' numbers, while nobody but you knows your chamber end length.

I personally prefer normal variances in trim lengths to being a mile from chamber end. When/if my brass is within 5thou of my chamber end, then I manage this, trimming minimal amount to same lengths. But my cartridges need little to no FL sizing.

Some cartridges(like your 270win) have to be sized more, stretch more, 10thou clearance should be manageable there.

I personally prefer normal variances in trim lengths to being a mile from chamber end. When/if my brass is within 5thou of my chamber end, then I manage this, trimming minimal amount to same lengths. But my cartridges need little to no FL sizing.

Some cartridges(like your 270win) have to be sized more, stretch more, 10thou clearance should be manageable there.

NorCalMikie

Gold $$ Contributor

"is it likely my cases would stretch .040” if I stopped trimming"??

Depends on the type of die you resize with. Regular full length sizer die with the "neck button" will pull the necks longer with every up stroke.

Shoulder bump/neck bushing dies will keep the OAL in check so the need to trim isn't very often.

Depends on the type of die you resize with. Regular full length sizer die with the "neck button" will pull the necks longer with every up stroke.

Shoulder bump/neck bushing dies will keep the OAL in check so the need to trim isn't very often.

Interesting. I would like to know the diameter of the Sinclair chamber length gauge. .278" or .308"? Just asking.View attachment 1095503

https://saami.org

I’m getting.3005 at the largest diameter of the insert...

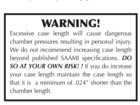

From Sinclair instructions. View attachment 1095528

Thanks...I saw this and would certainly watch that. Currently I’m .051” away from the end of my chamber... I really would be surprised if my cases would even begin to approach 2.581”. I’m resizing with a Forster FL die with neck honed .004” under then expanding to .002” under- expander button removed from sizing die.

Anyone should consider the credibility of 'recommended trim length' numbers, while nobody but you knows your chamber end length.

I personally prefer normal variances in trim lengths to being a mile from chamber end. When/if my brass is within 5thou of my chamber end, then I manage this, trimming minimal amount to same lengths. But my cartridges need little to no FL sizing.

Some cartridges(like your 270win) have to be sized more, stretch more, 10thou clearance should be manageable there.

In my shoes, you wouldn’t worry about a little variation in case length, instead giving the brass an opportunity to grow closer to chamber length. Something about trying to avoid a “carbon ring”? (I’ve no experience with this)

Martin I saw this and was interested. How does a custom dies help consistency ? Do you mean a die cut by the same reamer as the chamber ? or ? - thanks !

Re consistency, not quite. I was saying that I would always trim cases to the same length for consistency and to reduce a potential variable and then I went on to say (incidentally) that I also use a custom die. My custom dies are made not by the same reamer as the one cutting the chamber - rather by sending fired cases to the die maker.

Hope that helps/clarifies.

Martin

That's right. And given 4thou full length interference chosen for the necks, you've got way way more neck tension variance than trim length variance contributes anyway.

Help me out a bit, if you don’t mind. What am I doing to create neck tension variance, and what should I be doing differently. Having the neck honed to .004” less than OD of a loaded round seemed to be reasonable decision (at least at the time), and I thought the expanding mandrel would also help to uniform the necks. Thanks for your time.

An expanding mandrel will help. That's a good move.

But so much brass yielding up & down for every cycle is unnecessary and not 'good' for it, nor providing consistent action from it. That action, is spring back, and ideally you would work close to that. Normal spring back is ~1thou (max), so yielding occurs beyond that, and yielding is changing, and changing is change from consistent, bit by bit.

You're focused on necks, which could be constantly process annealed to counter, but what about shoulders & bodies?

Shoulders are an extension of FL sized necks. You bring this into play along with the donuts when you connect neck sizing to it. Again this is unnecessary, as partial length sized necks provides plenty of bullet grip (spring back).

And sizing length beyond seated bullet bearing, will not be expanded by that bearing, remaining in interference at the base-bearing junction. This is binding, and anything but consistent. This could represent bullet gripping that is way higher than normal or desired tension. Very high tension means higher variances of it.

There is nothing good in this.

If recoil/magazine loading is an issue to chosen CBTOs, then it would be better handled with a turned shelf for neck IDs than to FL size necks. Then you would not ever size that shelf, so that seated base-bearing junction would not be in binding connections with it.

But so much brass yielding up & down for every cycle is unnecessary and not 'good' for it, nor providing consistent action from it. That action, is spring back, and ideally you would work close to that. Normal spring back is ~1thou (max), so yielding occurs beyond that, and yielding is changing, and changing is change from consistent, bit by bit.

You're focused on necks, which could be constantly process annealed to counter, but what about shoulders & bodies?

Shoulders are an extension of FL sized necks. You bring this into play along with the donuts when you connect neck sizing to it. Again this is unnecessary, as partial length sized necks provides plenty of bullet grip (spring back).

And sizing length beyond seated bullet bearing, will not be expanded by that bearing, remaining in interference at the base-bearing junction. This is binding, and anything but consistent. This could represent bullet gripping that is way higher than normal or desired tension. Very high tension means higher variances of it.

There is nothing good in this.

If recoil/magazine loading is an issue to chosen CBTOs, then it would be better handled with a turned shelf for neck IDs than to FL size necks. Then you would not ever size that shelf, so that seated base-bearing junction would not be in binding connections with it.

Similar threads

- Replies

- 10

- Views

- 4,149

- Replies

- 32

- Views

- 2,277

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.