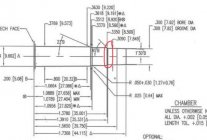

Has anyone used the 125 SMK for .300 BLK. I am getting weird pressure spikes using them. I know start low, work up yada yada all combinations of components are different. I picked up some 125 SMK pulls from American Reloading along with some primed brass which turned out to be 95% Ammo Inc. I pushed out the primers to look at them and they appear to be CCI 400s although I know visual comparison is sketchy at best. My go to load with 125 grain bullets in this gun is 17.9 gn of Win 296 with a WSR primer and I typically get 4-5 loads before primer pockets get a little loose. This load is sub MOA using: Nosler BT, Hornady SST, Speer TNT and Sierra SPT Pro-Hunter bullets. I have also used reformed: LC, Winchester, RP, PMC and Hornady brass as well as RP, GFL and PNW Arms .300 BLK brass, it's happy with any of them. This is a middle of the road load according to everyone's data. When I first got the bullets in I checked them for weight, OAL, diameter and all measurements were very consistent and were as expected. My first plan was to do a mini ladder shooting them into the ground outside my workshop. I loaded 17.3, 17.6 and 17.9 gn and all pieces of brass appeared normal. I loaded up 3 at 17.9 and went to the range and two of the three had brass flow into the ejector. I reduced to three each of 17.6, 17.3 and 17.0 and still got high pressure signs. I pushed out three of the primers and inserted some WSRs with the same result at 17.0. I used the three pushed out primers and used some reformed LC 5.56 brass at 17.0 gn with the same result. 17.0 gn is BELOW Sierra's starting charge for 125 SMKs for H110 which I think everyone knows is the same as W296. I attached a pic of the first group I shot at 17.9, second pic is the three pieces of brass with the WSR primers at 17.0. First I blamed the brass (too soft?), then the primers but now I think it's the bullet..... Thoughts?

Attachments

Last edited: