Wolfdog91

Silver $$ Contributor

So doing load development with my .243. Mossberg patriot.

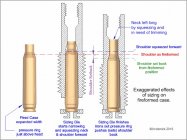

So took my measurements to help me do my initial shoulder bump off some older fire formed Hornady brass.

Used the Hornady D400 headspace gauge and anvil and got 1.624"off that brass.

Now new using new starline brass and my die (lee die and shell holder) wouldn't let me bump my shoulder past 1.623" prefer 0.003" bumb but always hear 0.001 i# perfectly fine for bolt guns so went with it.

Well went and fired all 50 pieces doing load work up , no noticeable pressure signs . But now when I measured it to see what these fire formed to their reading

1.621.... so the should went back...

Everything chambered just fine at 1.623 so I don't see how this could be much of a problem but.... Idk should I do anything special here or ?

Thanks

So took my measurements to help me do my initial shoulder bump off some older fire formed Hornady brass.

Used the Hornady D400 headspace gauge and anvil and got 1.624"off that brass.

Now new using new starline brass and my die (lee die and shell holder) wouldn't let me bump my shoulder past 1.623" prefer 0.003" bumb but always hear 0.001 i# perfectly fine for bolt guns so went with it.

Well went and fired all 50 pieces doing load work up , no noticeable pressure signs . But now when I measured it to see what these fire formed to their reading

1.621.... so the should went back...

Everything chambered just fine at 1.623 so I don't see how this could be much of a problem but.... Idk should I do anything special here or ?

Thanks