Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

setting up head space with out go gages

- Thread starter josebd

- Start date

butchlambert

Site $$ Sponsor

You're trying to do this without a barrel vise?

memilanuk

Gold $$ Contributor

Barrel vise and the proper wrench for the castle nut are pretty much required, particularly if you're removing a factory barrel for the first time. Especially if its one with any kind of coating (blueing, black oxide finish, etc.). Those come off really hard.

There *is* a redneck-ish way to loosen / tighten the nut in a pinch (if it was one that you tightened, not the factory) but there are people here who would have a conniption if I posted it

You *can* 'get away with' re-headspacing a barrel on a piece of fired brass. When you snug the barrel down hand tight against the case, and then tighten the nut, it takes up the slack in the threads and usually moves about an RCH (guesstimate of 0.001-0.002") just enough to allow you to open the bolt freely. Take the same case, set it on a piece of masking or painters tape and carefully trim around the case head. That tape is typically ~0.004" thick - about the same difference between a GO and a NO-GO gauge. If you re-insert it into the chamber, you shouldn't be able to lower the bolt handle. You might be able to *force* it, but thats not what we're going for here. This is a quick-n-dirty technique, and not one I'd recommend using regularly. The brass case can be 'sized' somewhat under rough handling, and the tape is definitely easy to damage/displace/thin.

That said.... if it's something you're going to be doing more than once, get a set of Forster GO/NO-GO gauges and do it right. For that matter, even if its something you're going to do only once, suck it up and get the gauges. You didn't have to pay for a gunsmith, so deduct it from your 'savings'.

Monte

There *is* a redneck-ish way to loosen / tighten the nut in a pinch (if it was one that you tightened, not the factory) but there are people here who would have a conniption if I posted it

You *can* 'get away with' re-headspacing a barrel on a piece of fired brass. When you snug the barrel down hand tight against the case, and then tighten the nut, it takes up the slack in the threads and usually moves about an RCH (guesstimate of 0.001-0.002") just enough to allow you to open the bolt freely. Take the same case, set it on a piece of masking or painters tape and carefully trim around the case head. That tape is typically ~0.004" thick - about the same difference between a GO and a NO-GO gauge. If you re-insert it into the chamber, you shouldn't be able to lower the bolt handle. You might be able to *force* it, but thats not what we're going for here. This is a quick-n-dirty technique, and not one I'd recommend using regularly. The brass case can be 'sized' somewhat under rough handling, and the tape is definitely easy to damage/displace/thin.

That said.... if it's something you're going to be doing more than once, get a set of Forster GO/NO-GO gauges and do it right. For that matter, even if its something you're going to do only once, suck it up and get the gauges. You didn't have to pay for a gunsmith, so deduct it from your 'savings'.

Monte

setting up head space with out go gages

Can it be done? Yes. Can the length of a chamber be measured in thousandths from the shoulder/datum to the bolt face with a head space gage? No. There are three head space gages as described, the go-gage, the no go-gage and the field reject length gage. That is three options, problem" Between go-gage and field reject length there are 11 options, if we are talking about the minimum length/full length sized case we are talking about 14 options. Still, the length of the chamber can be measured in thousandths without a go, no or beyond gage.

The go-gage is perceived as being a fixed length gage, I perceive it as being a variable length gage.

F. Guffey

What's wrong with doing it the right way. "STEEL GO and NO GO" gauges. Buy them, borrow them, steal them, I don't care. They don't lie and you and everybody can sleep a little better. Oh, don't forget to remove the ejector before your set the head space.

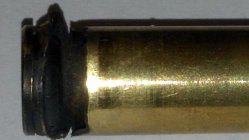

This is what can happen when not done correctly.

This was a 6mmBRX case head failure. The gun owner was a very experienced High Master Shooter, It was a Savage Model 10, and he got in a hurry. Yes, he is OK, both his gun and shorts took a hit, as did his squad partners shorts.

This is what can happen when not done correctly.

This was a 6mmBRX case head failure. The gun owner was a very experienced High Master Shooter, It was a Savage Model 10, and he got in a hurry. Yes, he is OK, both his gun and shorts took a hit, as did his squad partners shorts.

Attachments

What's wrong with doing it the right way. "STEEL GO and NO GO" gauges. Buy them, borrow them, steal them, I don't care. They don't lie and you and everybody can sleep a little better. Oh, don't forget to remove the ejector before your set the head space.

What's wrong with doing it the right way, make your own.

he got in a hurry.

I fail to see the connection between the high master getting into a hurry and not knowing what he was doing. I am the big fan of micrometers, standards and transfers.

F. Guffey

Warren Dean

Team Savage F-TR

Dans40X said:Applied torque variables will change headspace on your SALVAGE.

Butch-

It's a SALVAGE,anything is possible w/floating heads & nuts!

yeah,...they're pretty awful. :

Warren Dean

Team Savage F-TR

memilanuk said:Barrel vise and the proper wrench for the castle nut are pretty much required, particularly if you're removing a factory barrel for the first time. Especially if its one with any kind of coating (blueing, black oxide finish, etc.). Those come off really hard.

There *is* a redneck-ish way to loosen / tighten the nut in a pinch (if it was one that you tightened, not the factory) but there are people here who would have a conniption if I posted it

You *can* 'get away with' re-headspacing a barrel on a piece of fired brass. When you snug the barrel down hand tight against the case, and then tighten the nut, it takes up the slack in the threads and usually moves about an RCH (guesstimate of 0.001-0.002") just enough to allow you to open the bolt freely. Take the same case, set it on a piece of masking or painters tape and carefully trim around the case head. That tape is typically ~0.004" thick - about the same difference between a GO and a NO-GO gauge. If you re-insert it into the chamber, you shouldn't be able to lower the bolt handle. You might be able to *force* it, but thats not what we're going for here. This is a quick-n-dirty technique, and not one I'd recommend using regularly. The brass case can be 'sized' somewhat under rough handling, and the tape is definitely easy to damage/displace/thin.

That said.... if it's something you're going to be doing more than once, get a set of Forster GO/NO-GO gauges and do it right. For that matter, even if its something you're going to do only once, suck it up and get the gauges. You didn't have to pay for a gunsmith, so deduct it from your 'savings'.

Monte

+1 on the tape idea.

But I use Scotch tape...it's about .0015" thick. Works great.

Warren Dean said:memilanuk said:Barrel vise and the proper wrench for the castle nut are pretty much required, particularly if you're removing a factory barrel for the first time. Especially if its one with any kind of coating (blueing, black oxide finish, etc.). Those come off really hard.

There *is* a redneck-ish way to loosen / tighten the nut in a pinch (if it was one that you tightened, not the factory) but there are people here who would have a conniption if I posted it

You *can* 'get away with' re-headspacing a barrel on a piece of fired brass. When you snug the barrel down hand tight against the case, and then tighten the nut, it takes up the slack in the threads and usually moves about an RCH (guesstimate of 0.001-0.002") just enough to allow you to open the bolt freely. Take the same case, set it on a piece of masking or painters tape and carefully trim around the case head. That tape is typically ~0.004" thick - about the same difference between a GO and a NO-GO gauge. If you re-insert it into the chamber, you shouldn't be able to lower the bolt handle. You might be able to *force* it, but thats not what we're going for here. This is a quick-n-dirty technique, and not one I'd recommend using regularly. The brass case can be 'sized' somewhat under rough handling, and the tape is definitely easy to damage/displace/thin.

That said.... if it's something you're going to be doing more than once, get a set of Forster GO/NO-GO gauges and do it right. For that matter, even if its something you're going to do only once, suck it up and get the gauges. You didn't have to pay for a gunsmith, so deduct it from your 'savings'.

Monte

+1 on the tape idea.

But I use Scotch tape...it's about .0015" thick. Works great.

And I'll bet you drive a Dodge product

Tim Singleton

Gold $$ Contributor

IMO. And I've done a few savages. It didn't take me long to learn the slight cost of steel Go gauge was well worth it

The brass if used as a GO gauge will compress allwing the barrel to turn as you tighten down the nut. Making it sometimes impossible to close the bolt on new round. Even putting tape on a pc of brass won't help it will still compress. Steel doesn't compress.

The brass if used as a GO gauge will compress allwing the barrel to turn as you tighten down the nut. Making it sometimes impossible to close the bolt on new round. Even putting tape on a pc of brass won't help it will still compress. Steel doesn't compress.

Bluing Salt gets in the threads and makes it hard to get off for the 1st time. Also from the factory that mythical Gorilla that tightens them. ;D Of all the barrels I have done I have only used my action wrench on one, my fault for aggressively over tightening the nut. I have the Wheeler action wrench that I notched with a bastard file for the lug. I bought it before Jim started selling his wrench. I like using a barrel vise. Gauges are best, spend the money.

memilanuk

Gold $$ Contributor

Dgd6mm said:Bluing Salt gets in the threads and makes it hard to get off for the 1st time. Also from the factory that mythical Gorilla that tightens them.

When we toured the factory in 2009, they had a bottle of Loctite thread *sealer* - not thread locker. Also saw the torque wrench, set for 87 ft-lbs

Never had a problem with getting the barrel off of stainless guns.

Warren Dean

Team Savage F-TR

Warren Dean

Team Savage F-TR

Tim Singleton said:Even putting tape on a pc of brass won't help it will still compress. Steel doesn't compress.

The tape is used to establish that you got the head space correct by...oh, never mind.

I could explain it for you, but I can't understand it for you.

butchlambert

Site $$ Sponsor

Warren Dean,

I understand him. Brass cases will compress closing the bolt, a headspace gauge won't. I chamber mine to just close with a stripped bolt. If I have a used rifle I check it with a stripped bolt with both the go and no go.

I understand him. Brass cases will compress closing the bolt, a headspace gauge won't. I chamber mine to just close with a stripped bolt. If I have a used rifle I check it with a stripped bolt with both the go and no go.

Similar threads

- Replies

- 13

- Views

- 889

- Replies

- 15

- Views

- 2,071

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.