This is just to help inform you when i tune your scales

there are troubleshooting issues that are not easily evident and take time to resolve

People always ask "How much does it cost?"

it can vary, it will vary, and much of that depends on the amount of troubleshooting required

how many things are wrong, neglected etc to find and isolate any one particular problem by process of elimination of what could be several possible problems.

So understand, its the same as your car running funny and arbitrarily asking the mechanic how much its gonna cost

We dont know yet until we have the machine in our hands,

---------------

(AKA: Scale tuning is NOT always, a simple matter of touching up a few pivot points and cleaning the scale and weight checking it for calibration.

---

Here is one of my own personal scales I thought I would share that recently developed an ongoing issue I was having with it for awhile.

1. when removing the powder pan /// and the balance pointer dropping on the left side

--- and then replacing the powder pan back on the scale, it would not rise back up.

---it was acting as though there was a slight stickiness, catch in the pivots, maybe a rough spot?

or burr on the knives?

---but all it took was a slight bump of the finger and it would rise to balance on zero again very smoothly

---it did not always do this, but often enough to get tired of having to slightly touch the beam to get it going upward.

2. As I was playing with it, I remembered a similar problem I had with other scales,

---This being the fact that, when sitting close to the magnets, other metal parts can become magnetized over time, interfering with the scales swing and movement

---the simple solution is to remove said magnetized part, or block the magnetic lines of flux from said part, but how do you know which part is actually the magnetized culprit?

when everything is connected together? Thats one aspect why such issues take time to resolve.

And the reason there is no one set price for this kind of thing.

Shown are some pictures

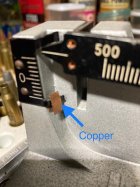

3. What I did was simply use a piece of copper shim to block the magentized pointer frame

---the scale now swings perfectly smooth as silk and is very sensitive and zeroes perfectly every time

when weighing a charge.

It took some time to isolate and trouble shoot that it was not a wear spot or burr in the knives, which would lead most of us to believe was happening

that it was not the pivot blocks that had a crack or divot in them,

it was not dirty at the pivot points from maybe a stuck tiny granule of W-748 wedged in there over the years, that the beam was not curved or bent causing erratic balance movement etc etc.

The Steel Pointer frame was so lightly magnetized it would barely hold onto the end of a paperclip suspended by a string - barely, almost imperceptible but that's all it takes to make a scale go Whacky.

---

Pic 1 - Shows the same type of scale with the pointer frame fully intact

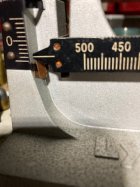

Pic 2 - Shows the same model of scale but with the perimeter of the frame broken off (on purpose)

and removed to eliminate the magnetized frame

---even still the bottom part of the frame would attract the pointer, and barely hold it there with about 0.5 grains of force

shown is the copper shim blocker, which freed up the movement as if there is no longer magnetic interference

Pic 3 - shows it zeroes perfectly without strange 0.1 grn up or down fluctuations in weight measurement one to the next

Pic 4 - Shows where it would "Get Stuck " or hang up when you set the powder pan down on the scale

Luckily the beam and pointer is not magnetized

Pic 5 - Another customers scale that had this little part which holds an extra weight at one end if you want to double the capacity of your scale from 500 to 1000 grns (how may of us use that feature lol?)

I had to use a carbide tool to remove that little part it was so hard to drill

If I didn't have some choice carbide tools for machining rifles, then what ?

I would have had to take the customers scale and paid another machinist an extra charge to fix it.

Luckily I have that kind of stuff on hand.

Pic 6 - shows where that little steel part would go on the scale

(So understand also - Some parts such as that must be removed to fix your scale)

---

If you are experiencing weird fluctuation issues or your scale does not swing perfectly smooth and zero at the same spot every single time, or more dangerously...

does not instantly move to reflect the slightest change in powder...

...Dont just live with it

You may send it to me

John

there are troubleshooting issues that are not easily evident and take time to resolve

People always ask "How much does it cost?"

it can vary, it will vary, and much of that depends on the amount of troubleshooting required

how many things are wrong, neglected etc to find and isolate any one particular problem by process of elimination of what could be several possible problems.

So understand, its the same as your car running funny and arbitrarily asking the mechanic how much its gonna cost

We dont know yet until we have the machine in our hands,

---------------

(AKA: Scale tuning is NOT always, a simple matter of touching up a few pivot points and cleaning the scale and weight checking it for calibration.

---

Here is one of my own personal scales I thought I would share that recently developed an ongoing issue I was having with it for awhile.

1. when removing the powder pan /// and the balance pointer dropping on the left side

--- and then replacing the powder pan back on the scale, it would not rise back up.

---it was acting as though there was a slight stickiness, catch in the pivots, maybe a rough spot?

or burr on the knives?

---but all it took was a slight bump of the finger and it would rise to balance on zero again very smoothly

---it did not always do this, but often enough to get tired of having to slightly touch the beam to get it going upward.

2. As I was playing with it, I remembered a similar problem I had with other scales,

---This being the fact that, when sitting close to the magnets, other metal parts can become magnetized over time, interfering with the scales swing and movement

---the simple solution is to remove said magnetized part, or block the magnetic lines of flux from said part, but how do you know which part is actually the magnetized culprit?

when everything is connected together? Thats one aspect why such issues take time to resolve.

And the reason there is no one set price for this kind of thing.

Shown are some pictures

3. What I did was simply use a piece of copper shim to block the magentized pointer frame

---the scale now swings perfectly smooth as silk and is very sensitive and zeroes perfectly every time

when weighing a charge.

It took some time to isolate and trouble shoot that it was not a wear spot or burr in the knives, which would lead most of us to believe was happening

that it was not the pivot blocks that had a crack or divot in them,

it was not dirty at the pivot points from maybe a stuck tiny granule of W-748 wedged in there over the years, that the beam was not curved or bent causing erratic balance movement etc etc.

The Steel Pointer frame was so lightly magnetized it would barely hold onto the end of a paperclip suspended by a string - barely, almost imperceptible but that's all it takes to make a scale go Whacky.

---

Pic 1 - Shows the same type of scale with the pointer frame fully intact

Pic 2 - Shows the same model of scale but with the perimeter of the frame broken off (on purpose)

and removed to eliminate the magnetized frame

---even still the bottom part of the frame would attract the pointer, and barely hold it there with about 0.5 grains of force

shown is the copper shim blocker, which freed up the movement as if there is no longer magnetic interference

Pic 3 - shows it zeroes perfectly without strange 0.1 grn up or down fluctuations in weight measurement one to the next

Pic 4 - Shows where it would "Get Stuck " or hang up when you set the powder pan down on the scale

Luckily the beam and pointer is not magnetized

Pic 5 - Another customers scale that had this little part which holds an extra weight at one end if you want to double the capacity of your scale from 500 to 1000 grns (how may of us use that feature lol?)

I had to use a carbide tool to remove that little part it was so hard to drill

If I didn't have some choice carbide tools for machining rifles, then what ?

I would have had to take the customers scale and paid another machinist an extra charge to fix it.

Luckily I have that kind of stuff on hand.

Pic 6 - shows where that little steel part would go on the scale

(So understand also - Some parts such as that must be removed to fix your scale)

---

If you are experiencing weird fluctuation issues or your scale does not swing perfectly smooth and zero at the same spot every single time, or more dangerously...

does not instantly move to reflect the slightest change in powder...

...Dont just live with it

You may send it to me

John

Attachments

Last edited: