Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RSI Pressure Trace

- Thread starter CharlieNC

- Start date

RegionRat

Gold $$ Contributor

For the money, it is a great way to get started in strain gage pressure measurement.

It has small quirks like anything complicated, but compared to typical lab equipment where the user has complete responsibility for the gage selection, scale factor calibration, data acquisition, and presentation, this system is turnkey and has all this worked out for you.

It has small quirks like anything complicated, but compared to typical lab equipment where the user has complete responsibility for the gage selection, scale factor calibration, data acquisition, and presentation, this system is turnkey and has all this worked out for you.

Walt Krafft

Gold $$ Contributor

The biggest problem I had was calibrating the system. Without some type of reference ammo for calibration, all you get is a number - no idea if it is high or low.

CharlieNC

Gold $$ Contributor

Did you learn any unique insight regarding load optimization, vs just pressure vs max?For the money, it is a great way to get started in strain gage pressure measurement.

It has small quirks like anything complicated, but compared to typical lab equipment where the user has complete responsibility for the gage selection, scale factor calibration, data acquisition, and presentation, this system is turnkey and has all this worked out for you.

It's a great piece of equipment. Yes, I use mine for safety purposes, but that's its secondary purpose. Mainly I use it for load optimization. As previously mentioned, there's no way to truly calibrate it without something like Oehler's system attached to it with a test barrel, but the differences between loads are completely representative, calibrated or not. Consistency between curve profiles from shot to shot can be easily scrutinized. A shot group that has initial ignition profiles all over the place, I avoid unless a higher charge weight tightens that up. Anything with an appreciable double spiked event, I treat exactly the same way, I avoid it. For someone that does a lot of load development, the unit can potentially pay for itself within a very short time, reducing a lot of frustration on the bench. Having said that, I do believe on one of my rifles, I'm within plus or minus 1% of actual based on quite a few different data points provided by Hodgdon, Western and others who list pressures with certain loads. Below are a couple of pics of what I'm talking about above.This has been around quite a while, but I never see anyone reporting results using it. The RSI web site claims it is useful to optimize a load, including seating depth. Anybody using this and finding anything interesting?

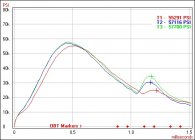

The first one is a three shot work up load, one grain apart for each shot. Red is lowest, blue, then green. Notice how the secondary pressure spike continues to rise. The ONLY instrument or observation that will see something like this is the Pressure Trace II. Observing brass, primers, bolt lift, etc. will never notice this phenomenon.

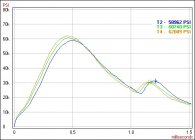

This next one is also the beginning of a five shot load work up sequence. The initial pressure was far higher than expected, and I've looked at enough of these graphs to know that the second curve had a strange, rounded dome look, and was significantly higher, as was the velocity, for only an additional grain of powder. No pressure signs existed other than looking at the Pressure Trace. I pulled the three remaining bullets. Problem solved, BEFORE the problem exhibited bad behavior. Look at that nasty secondary spike as well, and this from a single-based powder. Velocity was very slow too. I mean, absolutely nothing good to say about this combo.

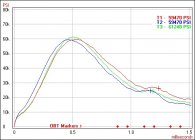

These next two graphs are really interesting, and both are identical load work-up charge weights shot at different outside ambient temperatures, about 27 degrees apart, the first chart at 91 and the second at 64. Reloder 16 is touted as being a temp stable powder, but for this combo I will definitely pass, for several reasons seen and described below. The 91 degree graph was shot first. As the season cooled, the 64 degree was shot. Look at how the area under the curve predominantly changed. HIGHER peak pressure and velocity were seen at the cooler temps as well, and the area under the curve was noticeably more "nervous" in the cooler temps with a prominent secondary spike. I didn't care for the shot start initiation profile in the cooler temps either. Surprisingly, both groups, even though none were of the same charge weight shot fairly well at 100 yards. Very weird, but nobody would ever know this is taking place without a Pressure Trace.

Here's a factory load shot group. Look at the shot start initiation variation. It's all over the place. The crosshairs represent calculated muzzle exit times. You can imagine this shot group wasn't that good.

Last but not least, here's one of my pet loads. This is not a workup, but rather a shot group. Look at the consistency, especially at the beginning, which is the most critical. Also take note of the OBT (optimal barrel timing) marker location and the calculated muzzle exit, which is directly over the top of it. Yes, this is merely a calculation, but I've found it to be correct for my setup with all the premeasured inputs properly accounted for.

Thought I'd help by providing a bit of color from a Pressure Trace customer and my experience. It has immensely reduced the time it takes me to find a combo worth tweaking on, while providing a bit of peace of mind safety-wise as well. I hope this helps.

Quick Edit: I realized one of the Re-16 graphs was a wrong sequence. It's been updated to the correct one. Since I had only captured three on that particular one, I deleted the matching shot on the other graph to reduce confusion. Thanks.

Last edited:

Jager

Gold $$ Contributor

Thanks for the thoughtful description of your experiences with the RSI device, @mcdil (great first post!).

The secondary pressure spike in your graphs... do you typically see those on most your Pressure Trace measurements?

The reason I ask is that most graphs from ballistics labs depicting chamber pressures do not show that kind of secondary pressure spike. Secondary Explosion Effects, or detonation, is a widely accepted phenomenon in the ballistics world, but it is considered to be both somewhat rare and difficult to reproduce. It's usually associated with reduced charges of slow burning powders.

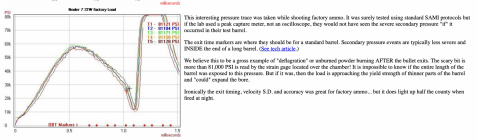

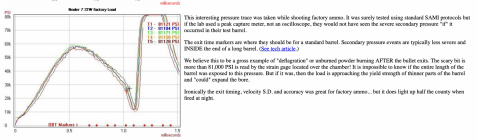

I've wandered over to the RSI site a number of times looking at the Pressure Trace. The thing that gives me pause, that has prevented me from buying it, is the question of its accuracy. For example, here is a snapshot, an example from the RSI website, that purportedly depicts a significant, very severe secondary pressure spike, of factory ammo, after the bullet has exited the barrel.

I frankly don't believe this graph to be remotely accurate. And so it leads me to question the reliability and accuracy of the Pressure Trace system.

If anyone can articulate how and why that RSI graph is accurate, I'd love to hear it. I routinely model chamber pressures in QuickLoad - my primary use of that program. That works pretty well. But I would love to be able to measure pressure directly.

The secondary pressure spike in your graphs... do you typically see those on most your Pressure Trace measurements?

The reason I ask is that most graphs from ballistics labs depicting chamber pressures do not show that kind of secondary pressure spike. Secondary Explosion Effects, or detonation, is a widely accepted phenomenon in the ballistics world, but it is considered to be both somewhat rare and difficult to reproduce. It's usually associated with reduced charges of slow burning powders.

I've wandered over to the RSI site a number of times looking at the Pressure Trace. The thing that gives me pause, that has prevented me from buying it, is the question of its accuracy. For example, here is a snapshot, an example from the RSI website, that purportedly depicts a significant, very severe secondary pressure spike, of factory ammo, after the bullet has exited the barrel.

I frankly don't believe this graph to be remotely accurate. And so it leads me to question the reliability and accuracy of the Pressure Trace system.

If anyone can articulate how and why that RSI graph is accurate, I'd love to hear it. I routinely model chamber pressures in QuickLoad - my primary use of that program. That works pretty well. But I would love to be able to measure pressure directly.

XTR

F-TR obssessed shooting junkie

I like mine a lot, but the idea of this piece of kit appeals to the more OCD among us and as noted above many people can't get their heads around the calibration and knowing the exact number.

I've used it to test coated vs non coated bullet pressure curves, and to test new powders and bullets against known loads in my barrels.

I've used it to test coated vs non coated bullet pressure curves, and to test new powders and bullets against known loads in my barrels.

CharlieNC

Gold $$ Contributor

I like mine a lot, but the idea of this piece of kit appeals to the more OCD among us and as noted above many people can't get their heads around the calibration and knowing the exact number.

I've used it to test coated vs non coated bullet pressure curves, and to test new powders and bullets against known loads in my barrels.

Did those evaluations reveal anything useful vs just using the target?

@Jager I really think the correctness of the bullet exit timing is a function of correct inputs combined with a normal pressure curve. I think if one or both of those things are off, the exit time will be less correct. Remember, that part is only a calculation, not an actual measurement. I'd always confirm with a particular combo that the exit markers are close through normal load development work. In the case of one of my rifles, they are, so I now use it for that work exclusively.

For the one you showed from the RSI website, I agree with you. I've actually had that discussion with the owner at length. If you look at my graph above that only has two shots, you'll notice the exit markers where you wouldn't envision them to be, similar to the one you showed, just not as far off. I do believe the pressure spikes are there, however. That's a function purely of strain over time, and that IS a measurement. Have you ever noticed how some loads are just substantially louder than others? This could very well be a good explanation, and it definitely seems to line up with the readings I get. When I get those readings, they don't show as an anomaly. They're consistent within loads, and distinct between loads. It's real.

As far as Quickload, I used that a lot prior to getting a Pressure Trace II. When I first set up Quickload with two bullets I had never shot before, one not even in the system (I created its profile), I had incredibly good success, or so I thought. Just to show what the two quick workup loads did, here's the anticipated and actual velocities of each. It was almost spooky it was so close. The second one's slope of change was off just a tad, but not much. I thought I was onto something.

1st Bullet/Powder

Anticipated Vel Actual Vel

3017 3017

3078 3076

3139 3145

3198 3198

2nd Bullet/Powder

Anticipated Vel Actual Vel

3295 3267

3363 3345

3429 3429

3495 3509

However, in the case of the second one, that happens to be what the growing secondary spike graph represents. After my initial success, I then continued to struggle to get velocities anywhere near that precise from there with other powders, different seating depths and neck tension, etc. It wasn't until I started using the Pressure Trace II, did I really get a full picture of everything, which I then realized it was truly impossible for Quickload to account for all the sensitive variables, especially weird, unfavorable events. I now use it for case volume analysis, and I may even take a peek at the burn percentage before setting out on load development. From there, it's Pressure Trace all the way.

For the one you showed from the RSI website, I agree with you. I've actually had that discussion with the owner at length. If you look at my graph above that only has two shots, you'll notice the exit markers where you wouldn't envision them to be, similar to the one you showed, just not as far off. I do believe the pressure spikes are there, however. That's a function purely of strain over time, and that IS a measurement. Have you ever noticed how some loads are just substantially louder than others? This could very well be a good explanation, and it definitely seems to line up with the readings I get. When I get those readings, they don't show as an anomaly. They're consistent within loads, and distinct between loads. It's real.

As far as Quickload, I used that a lot prior to getting a Pressure Trace II. When I first set up Quickload with two bullets I had never shot before, one not even in the system (I created its profile), I had incredibly good success, or so I thought. Just to show what the two quick workup loads did, here's the anticipated and actual velocities of each. It was almost spooky it was so close. The second one's slope of change was off just a tad, but not much. I thought I was onto something.

1st Bullet/Powder

Anticipated Vel Actual Vel

3017 3017

3078 3076

3139 3145

3198 3198

2nd Bullet/Powder

Anticipated Vel Actual Vel

3295 3267

3363 3345

3429 3429

3495 3509

However, in the case of the second one, that happens to be what the growing secondary spike graph represents. After my initial success, I then continued to struggle to get velocities anywhere near that precise from there with other powders, different seating depths and neck tension, etc. It wasn't until I started using the Pressure Trace II, did I really get a full picture of everything, which I then realized it was truly impossible for Quickload to account for all the sensitive variables, especially weird, unfavorable events. I now use it for case volume analysis, and I may even take a peek at the burn percentage before setting out on load development. From there, it's Pressure Trace all the way.

XTR

F-TR obssessed shooting junkie

I didn't/don't use it to develop loads for accuracy. I use it to develop load ranges for components that are not typically listed in tables then develop loads with that information in hand.Did those evaluations reveal anything useful vs just using the target?

I found that coated bullets to in fact lower pressure for a given load; with an expected lower MV, but to get back to the uncoated MV you are basically back at the same original pressure for no net gain. At least my data tells me that people who think they can run coated faster seem to be getting the results they want to see.

I used it testing 308 loads for 215 hybrids to see where the pressure was comparable to known 200 loads with different powders looking for powders that gave good MVs with lower pressures.

I've most recently used mine to compare loads in my 308 with Berger 208s loaded with N150 compared to Reloader 15.5. What I found that was for a given velocity the Re15.5 loads are running lower pressures. I think that data is useful to bound the upper limits of my loads and whether or not I can reach a "higher node" with the different powder. That testing is not complete and I have not developed any loads with the Reloader powder yet.

Edit: another bugaboo for small primer brass that it reveals quite clearly is delayed ignition. All of my 308 loads exhibit it to some degree with SRPs. It was part of the reason that I began to recognize the problem I was having with some old Tula primers I have and why I switched to 205m's. The delay is still there, just not as bad or as variable. As an extension of this data it also tells me that SRPs could likely be a problem for the slower powders run in short action 6mms.

Last edited:

Similar threads

- Replies

- 80

- Views

- 6,479

- Replies

- 29

- Views

- 7,912

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.