Just thought I would share my experience removing the barrel from a Tikka t3 lite. This task has a reputation for being extremely difficult. I purchased the gun way back around 2008, and it has been hunted hard and taken many a varmint, predator, and a wild boar.

I put it in a vise action up and sprayed it with kroil periodically for 6 or maybe 8 weeks. The barrel vice wouldn't hold tight enough after the tapper at the chamber cuz it's too small. I then tried some leather around it to make it thicker, still not tight enough. I ended up clamping the heck out of it on the tapered section at the chamber. Thought I might ruin the barrel vice. It did damage 2 of the 4 springs due to the extreme angle. I will call and get a couple new springs, but I don't even think they are needed. They are only to hold the vise open as you insert the barrel.

Then i beat the heck out the wheeler #1 action wrench with a 3lb sledge. Oh, and i put some cardboard from a 12 pack around the action to protect it. It came off with zero damage to the action!

Upon inspection, I didn't see that the kroil had penetrated the threads at all. It had some dark brown I guess was corrosion that had got really hot. There was some white stuff I think was thread locker or rockset, not grease.

I cleaned up the threads of the action with a 1 inch fitting brush for plumbing and flushed the whole action with breakfree clp. I dont care for that stuff, so I was happy to get it out the garage. Got the excess clp out with shop towels, q tips, and the compressor.

Preferred Barrel Blanks shouldered prefit 8 twist 223 AI 24" lite hybrid ordered!

If I can do it, you can do it! From here on out it should be easy to remove the barrel.

A couple of tips.

If you are going to use penetrating oil, it is best to put a little in each day (shoot it into the action) and store the rifle barrel down.

Use drywall tape around the barrel. It will hold better than even leather and not mar your finish.

When using the Wheeler action wrench, clamp it back from the barrel/action junction a bit. I usually have that very front scope rail screw covered up. Also, don't crank down on the bolts for the wrench. Doing these things prevent the action wrench from clamping the action down on the barrel threads.

Once you have the barrel clamped down in the vice (if you think you have the nuts tightened down, give them another 1/4 turn), put a 4X4 or two 2X4s that are screwed together under the action to prevent it from flexing downward. This will ensure that all of the force is imparted to rotation rather than downward.

Rather than using a sledgehammer on the wrench, use a deadblow hammer.

Doing this has loosened every factory Tikka barrel I have taken off (up to 5 now) with one smack of the hammer.

I had to use two barrel vices on one.

A couple of tips.

If you are going to use penetrating oil, it is best to put a little in each day (shoot it into the action) and store the rifle barrel down.

Use drywall tape around the barrel. It will hold better than even leather and not mar your finish.

When using the Wheeler action wrench, clamp it back from the barrel/action junction a bit. I usually have that very front scope rail screw covered up. Also, don't crank down on the bolts for the wrench. Doing these things prevent the action wrench from clamping the action down on the barrel threads.

Once you have the barrel clamped down in the vice (if you think you have the nuts tightened down, give them another 1/4 turn), put a 4X4 or two 2X4s that are screwed together under the action to prevent it from flexing downward. This will ensure that all of the force is imparted to rotation rather than downward.

Rather than using a sledgehammer on the wrench, use a deadblow hammer.

Doing this has loosened every factory Tikka barrel I have taken off (up to 5 now) with one smack of the hammer.

Did most of that. Too cheap for a deadblow, I even looked at harbor freight. Too cheap for the drywall tape too lol. Bidenomics at work! I had seen those things recommended. Another I had seen was putting powdered sugar in the leather to act as rosin, also too cheap. Another was heat, but I dunno if its my torch or the map gas can, but it was leaking gas. I was a journeyman plumber, so I had that, but haven't used it in 8 years.

My current goal with another Tikka is 100 rds of 223 every weekend till it burns out, so I will do this again. I have read newer guns are easier, but also there won't be any corrosion. I had a smith do 1 Tikka t3 circa 2010 cuz I was afraid to try it.

After I purchased the Sinclair barrel vise Tikka barrels are a breeze. The correct size bushing for the barrel and a small tap with a dead blow hammer is generally all she needs.

HOLD INTO THE WIND.

Silver $$ Contributor

Can someone please post a picture or a link to a dead blow hammer ?

I would like to know exactly what this is ..

Thanks

Jim

Can someone please post a picture or a link to a dead blow hammer ?

I would like to know exactly what this is ..

Thanks

Jim

Hired Gun Painting

Silver $$ Contributor

Can someone please post a picture or a link to a dead blow hammer ?

I would like to know exactly what this is ..

Thanks

Jim

Phones ringing

Runs with scissors

Gold $$ Contributor

What size bushing would one get for this vise for the Tikka?

Brownells Vise

Did most of that. Too cheap for a deadblow, I even looked at harbor freight. Too cheap for the drywall tape too lol.

I, too, use a Viper barrel vise. I use a strip of old toilet paper core against the barrel (paper towel core would work as well, with less of a stigma) followed by a square of leather, then crank down on the nuts. On my bench gun, after loosening the smith's mounting job, I usually just smack the base of the barrel vise with the ratchet to loosen or tighten. Works for me.

First I drink the coffee, then I do the things.

Gold $$ Contributor

I, too, use a Viper barrel vise. I use a strip of old toilet paper core against the barrel (paper towel core would work as well, with less of a stigma) followed by a square of leather, then crank down on the nuts. On my bench gun, after loosening the smith's mounting job, I usually just smack the base of the barrel vise with the ratchet to loosen or tighten. Works for me.

Oh, that is excellent! Made my day, sir! Take care not to show preference, or the shorter tube will start a nationwide movement...

Great tips here on removal...

Got it ‘ thanks.. without the coatings~ just steel head and wooden handle we would call that a double jack, typically a 2 pounder used for driving hub’s

Jim

A dead blow has dense loose material inside the hollow head. It is not a solid head.

I have a Tikka build coming up this winter, good tips for removal’ I don’t intend on torquing the new barrel to more than about 50-60 foot pounds.

Seems 70 to 90 is usually the recommended spec.

I also call a little sledge hammer a single jack. Never heard of double jack. Figured nobody would know what a single jack is. I dont see how a dead blow makes a difference other than not damaging the handle of the action wrench, which I dont care about. A dead blow is not just coated solid steal. They have beads or something in it.

The toilet paper or paper towel tube was also commonly recommended as well as business cards.

Unless you care about the factory barrel it doesn't matter much. Installing and removing the new one just about anything should work as its only like 70ft lbs and the threads will be greased.

Seems 70 to 90 is usually the recommended spec.

I also call a little sledge hammer a single jack. Never heard of double jack. Figured nobody would know what a single jack is. I dont see how a dead blow makes a difference other than not damaging the handle of the action wrench, which I dont care about. A dead blow is not just coated solid steal. They have beads or something in it.

The toilet paper or paper towel tube was also commonly recommended as well as business cards.

Unless you care about the factory barrel it doesn't matter much. Installing and removing the new one just about anything should work as its only like 70ft lbs and the threads will be greased.

Aside from the reduced shock on your hands, a dead blow keeps its forward momentum when striking something springy. This is not just safer, it transfers more total energy. (If your hammer is bouncing, it’s not transferring energy well)

Back to the OP, my gunsmith took one look at my Tikka and turned an undercut at the barrel shoulder. Then it came off with relative ease and no risk of damaging the receiver.

When an old man dies, a library is lost forever...

Good tools will last a lifetime…

But if it’s cost, many auto parts houses will loan tools. And you are likely to need oil, washer fluid, grease or rags anyway…

Aside from the reduced shock on your hands, a dead blow keeps its forward momentum when striking something springy. This is not just safer, it transfers more total energy. (If your hammer is bouncing, it’s not transferring energy well)

Back to the OP, my gunsmith took one look at my Tikka and turned an undercut at the barrel shoulder. Then it came off with relative ease and no risk of damaging the receiver.

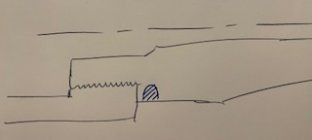

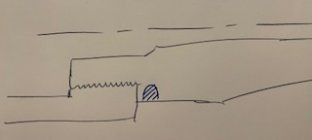

would you pls draw a picture of the undercut at barrel shoulder? so I can understand.

would you pls draw a picture of the undercut at barrel shoulder? so I can understand.

Once you machine this groove (in blue) the thin metal remaining can’t support the preload on the shoulder and the torque on the threads is vastly reduced.

-

IMG_6594.jpeg

13.2 KB

· Views: 72

Once you machine this groove (in blue) the thin metal remaining can’t support the preload on the shoulder and the torque on the threads is vastly reduced.

Thank Y!

Try a 50/50 mix of ATF and Acetone instead of store bought penetrating oil. Apply a couple of times a day for a week. I tear a strip off a shop rag and wrap it around the barrel where is meets the action. Soak the strip of rag, that holds the oil where you want it.