VA_XTC_Shooter

Silver $$ Contributor

I am going to chamber a new barrel for my 223 Borden action in an Eliseo chassis (0.200” recoil disc).

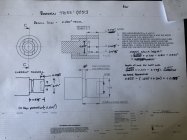

I took the measurements from the action per the attached remington 700 build sheet.

I noticed some wear marks on the front of the bolt lugs so I measured the barrel that came on the rifle (no clue who chambered it, no markings and bought gun used).

There are quite a few discrepancies in what measurements I took and what the build sheet recommends and what the old barrel was cut to.

It appears the old barrel was cut to tighter tolerances (tenon length and bolt nose clearance).

This made me question the calculations on the build sheet. The tenon length difference is just a difference of clearance added in, same as the counterbore depth. But I am struggling to understand why the headspace protrusion is so different (+0.007 vs -0.014).

I would think tenon length should be .832" (0.002 crush and 0.008" clearance from lugs).

Counterbore should be 0.147 or .148 like the current barrel because the crush and clearance is already accounted for in the 0.832" tenon length.

The Go Gage protrusion, appears to again be correct in the current barrel at -.014" allows for 0.002 crush and 0.001" over 0.

I took the measurements from the action per the attached remington 700 build sheet.

I noticed some wear marks on the front of the bolt lugs so I measured the barrel that came on the rifle (no clue who chambered it, no markings and bought gun used).

There are quite a few discrepancies in what measurements I took and what the build sheet recommends and what the old barrel was cut to.

It appears the old barrel was cut to tighter tolerances (tenon length and bolt nose clearance).

This made me question the calculations on the build sheet. The tenon length difference is just a difference of clearance added in, same as the counterbore depth. But I am struggling to understand why the headspace protrusion is so different (+0.007 vs -0.014).

I would think tenon length should be .832" (0.002 crush and 0.008" clearance from lugs).

Counterbore should be 0.147 or .148 like the current barrel because the crush and clearance is already accounted for in the 0.832" tenon length.

The Go Gage protrusion, appears to again be correct in the current barrel at -.014" allows for 0.002 crush and 0.001" over 0.

Attachments

Last edited: