The V series Turbo actions have always been manufactured and assembled to facilitate barrel interchangeability for extractor slot barrels.You might take note as to why, I suspect, Jerry does that.

The 2500’s are about the only threaded action made with tolerances so close you can reliably swap barrels between them, i.e. action specific.

That said, with different approaches to tighten the barrel, the fit is fine but the extractor slots may not match up perfectly every time, especially if cut close, thus the milled breach, eliminating the issue…..kind of an exception to the “ rule” if you will.

Barrels done properly, with proper slots, in my experience, don’t get misaligned, but guys that swap barrels use anything from “ snap tight” to 100lb’s+ so slots can get tighter than ideal.

I’m with TKH. I want that barrel to butt up tight to the action face. If I want to swap barrels it’s with another fit to that action.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pros cons

- Thread starter double g

- Start date

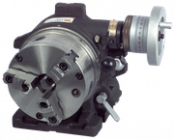

The angled extractor slots of my two V22S actions didn't make it any easier to cut them, but that's one advantage to using the super spacer-indexer fixture. The rotating plate is marked in degrees, as is the crank, which has vernier markings. These are the only actions with angled slots that I've done barrels for, and I'd hate to try to do them without that fixture...Flatlander,

The trash can collector idea is certainly out of the box thinking.

If the extractor and ejector are located at 180 degrees in the bolt, cutting slots is just as easy as cutting a cone. If they are set at an angle, it can make it a white-knuckle process.

As far as I know the angle serves no purpose other than to frustrate smiths working with manuel machines. It is certainly not done to make loading easier as proven by later Turbo designs.

TKH

Would you please post a pic of the fixture and tell us where you got it. It sounds like a good tool to have.The angled extractor slots of my two V22S actions didn't make it any easier to cut them, but that's one advantage to using the super spacer-indexer fixture. The rotating plate is marked in degrees, as is the crank, which has vernier markings. These are the only actions with angled slots that I've done barrels for, and I'd hate to try to do them without that fixture...

TKH

Would you please post a pic of the fixture and tell us where you got it. It sounds like a good tool to have.

TKH

After I pasted a copy of the super indexing spacer from the Vertex website, it wouldn't allow me to enter any text. Mine looks just like the Vertex, but was purchased from MSC not long after I bought my JET knee mill, which is a made in Taiwan clone of our Bridgeport. That was in 2005, and I don't recall what I paid for it then, but it's a safe bet it was far less than what they're advertised for today...

ETA - it's not obvious from the photo I posted, but the spacer can be set up in either vertical or horizontal position.

ETA - it's not obvious from the photo I posted, but the spacer can be set up in either vertical or horizontal position.

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.