I recently picked up a K+M SRP pocket uniformer and decided to try it on a lot of FC 6.5CM brass. During load testing everything appeared normal. Took the rifle to a match and i was getting 1 in 20 cases that had hard bolt lift and a very distinct gas leak around the primers. Cleaning the rifle after the match, i noticed that some of these cases actually cratered my bolt face and i went through the lot of brass and found where about 5 of the lot of 250, combustion gasses cut through the outer edge of the primer and damaged my bolt face.

My question is did uniforming my primer pockets lead to this result, or did my lot of brass just need to be retired? ive had primer pockets fail before, but not with this result. Im extremely hesitant to experiment with this anymore as i do not want to damage my bolt anymore. I have a spare, but best not to poke the bear.

Its a spicey load using H4350, FC SRP brass, Winchester #41 primer, Hornandy 147ELD.

Hard bolt lift and gas leaks around primers is pointing to a load that is too hot. Squaring up the primer pockets didn't do that. New lot of powder maybe?

I recently picked up a K+M SRP pocket uniformer and decided to try it on a lot of FC 6.5CM brass. During load testing everything appeared normal. Took the rifle to a match and i was getting 1 in 20 cases that had hard bolt lift and a very distinct gas leak around the primers. Cleaning the rifle after the match, i noticed that some of these cases actually cratered my bolt face and i went through the lot of brass and found where about 5 of the lot of 250, combustion gasses cut through the outer edge of the primer and damaged my bolt face.

My question is did uniforming my primer pockets lead to this result, or did my lot of brass just need to be retired? ive had primer pockets fail before, but not with this result. Im extremely hesitant to experiment with this anymore as i do not want to damage my bolt anymore. I have a spare, but best not to poke the bear.

Its a spicey load using H4350, FC SRP brass, Winchester #41 primer, Hornandy 147ELD.

Don't know how old the Winchester primers may have been that were involved in this incident. But several years ago there was a problem with several lots of Winchester LRP's that involved failure of the cups cracking around the od of the face of the primer. I experienced this personally. Search of this site may lead you to the lot numbers involved.

Any problems with seating the primers.

It's the Federal brass there primer pockets are weak . Switch to Lapua srp brass and you won't have that issue.

Is the cutting in the shape of a ring or an irregular indention. A picture would help.

I never ever touch primer pockets. Hell I don't even clean them after firing.

Primer seating felt normal for this lot. I seat with a RCBS hand primer. I have been using this combo during the component shortage with relatively decent success. I can typically keep my SD's in the single digits and groups are .5"-.75".

I have lapua brass and use it with CCI450's with stellar results, but ive never touched the primer pockets in any of those lots, so i cant really compare whats going on here between manufacturers. Yes, I love Lapua brass too, but this combo is kinda like a cheapskate/default load that i can always fall back on and have a good stash of these components that i want to use up during these components and pricing fiasco's. I have been using Federal brass for years with great success, and ive never experienced this particular issue. *with the understanding that federal brass has its shortcomings and limitations.*

This is my first time messing with a primer pocket.... and now i have a damaged rifle. I think I'll trash this lot of brass and leave them alone from here on out. I didnt gain anything out of the experiment as far as SD's/ES is concerened.

I will post some pics later today.

High pressure, reduce powder charge below 41.8 grs. Hodgdon Data, with HORNADY BRASS. My guess.

Hard bolt lift is a sign of an over pressure load. Is there bolt swipe on the brass? If its over pressure then you may be expanding pockets.

High pressure, reduce powder charge below 41.8 grs. Hodgdon Data. My guess.

I am under listed max, but federal brass has a different capacity.

Hard bolt lift is a sign of an over pressure load. Is there bolt swipe on the brass? If its over pressure then you may be expanding pockets.

No swipe, no ejector marks.

Hired Gun Painting

Silver $$ Contributor

I'm gonna say its 3 things going on and uniformity pockets ain't 1 of them.

Stout load

Weak FC brass/ poor pockets

Winchester primers are smaller diameter.

I've never etched a bolt face using Winchester primer in Hornady, RP, Lapua, Norma, and Nosler brass.

I always uniform the pockets when doing brass prep.

Could try a different brand of primer? But the small rifle primers may need to be MAGNUMS to get a thick cup metal.

CCI450's

Could try a different brand of primer? But the small rifle primers may need to be MAGNUMS to get a thick cup metal.

CCI450's

The Winchester #41 WMSRL is listed and sold as a NATO specification primer for 5.56X45mm. Unless Winchester has made a hash of it, you shouldn't get anything tougher than that.

https://www.midwayusa.com/product/1023007962

Almost certainly an overload as most posts say, maybe with the Federal brass having less capacity than other makes too. I've no experience of it in this cartridge, but in others where I've used it, soft case-heads plus reduced capacity = avoid 'stiff' loads.

My question is did uniforming my primer pockets lead to this result, or did my lot of brass just need to be retired?

Did you increase the diameter of the primer pockets when you uniformed them?

I recently picked up a K+M SRP pocket uniformer and decided to try it on a lot of FC 6.5CM brass. During load testing everything appeared normal. Took the rifle to a match and i was getting 1 in 20 cases that had hard bolt lift and a very distinct gas leak around the primers. Cleaning the rifle after the match, i noticed that some of these cases actually cratered my bolt face and i went through the lot of brass and found where about 5 of the lot of 250, combustion gasses cut through the outer edge of the primer and damaged my bolt face.

My question is did uniforming my primer pockets lead to this result, or did my lot of brass just need to be retired? ive had primer pockets fail before, but not with this result. Im extremely hesitant to experiment with this anymore as i do not want to damage my bolt anymore. I have a spare, but best not to poke the bear.

Its a spicey load using H4350, FC SRP brass, Winchester #41 primer, Hornandy 147ELD.

Uniforming increases the depth of the pocket to some depth. It does not change the pocket o.d. and tightness. Hot loads!

My Rem 788 in .222 suffered that same damage years ago. Brass was #3 fired W-W, H4198 and a 50gr. Speer. Primers were Federal. In the heat of dogtown action this went on unnoticed. A third of the 100 ct. box had primers with a side split leading to a tiny burn through hole. Not a big deal to me with a low dollar rifle.

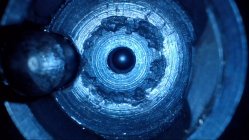

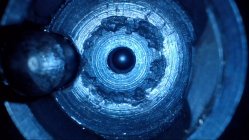

Photo just taken with a Teslong bore scope with mirror removed.

-

Snap_001.jpg

516.5 KB

· Views: 38

How long you been using Federal brass. My guess that is the culprit. I don’t waste my time reloading Federal Brass.

Competitive shooter and reloader for 50 years+

Gold $$ Contributor

No swipe, no ejector marks.

This is the very reason you should not monitor pressure by ejector marks, bolt swipe, or flattened primers. So I'll ask the scientific question what was your head diameter when you started and what is it now? Sounds to me your pockets are loose. Loose enough where you will get gas leakage with a very high pressure load and cause a "fairy ring" on the bolt face, ie. the head diameter of your cases has enlarged due to repeated exposure to very high pressure. That repeated high pressure on your brass may not show up right away. That's why it's so important to monitor head diameter. Any expansion of more than .0008" will certainly lead to problems. Another question does your rifle have a small diameter firing pin for small primers?