You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Powered Neck Turning?

- Thread starter jbpmidas

- Start date

Erik Cortina

Team Lapua Brux Borden Captain

Define "reasonably priced"

How much are you willing to spend?

How much are you willing to spend?

ridgeway

Silver $$ Contributor

Get yourself a Dewalt 18v cordless drill or equivalent from Amazon. You want something that sits nice and stable on the bench.

http://www.amazon.com/DEWALT-DC970K-2-18-Volt-Drill-Driver/dp/B002RLR0EY

http://www.amazon.com/DEWALT-DC970K-2-18-Volt-Drill-Driver/dp/B002RLR0EY

http://www.amazon.com/Black-Decker-LDX220SBFC-20-Volt-Lithium-Ion/dp/B008YSHD0K/ref=sr_1_26?s=power-hand-tools&ie=UTF8&qid=1369319371&sr=1-26

The nice thing with a drill, it can come in handy elsewhere in your house.

http://www.amazon.com/DEWALT-DC970K-2-18-Volt-Drill-Driver/dp/B002RLR0EY

http://www.amazon.com/DEWALT-DC970K-2-18-Volt-Drill-Driver/dp/B002RLR0EY

http://www.amazon.com/Black-Decker-LDX220SBFC-20-Volt-Lithium-Ion/dp/B008YSHD0K/ref=sr_1_26?s=power-hand-tools&ie=UTF8&qid=1369319371&sr=1-26

The nice thing with a drill, it can come in handy elsewhere in your house.

Erik Cortina

Team Lapua Brux Borden Captain

Happiness costs more than $50.00.

jbpmidas

MR F-T/r

Erik Cortina said:Happiness costs more than $50.00.

No argument there!

My favorite power source for neck-turning is a Bosch 10 volt L-Ion drill. So light and easy to use that my wife has appropriated it and I now have a Milwaukee 12 volt L-Ion drill. That works just as well but the batteries don't last as long for whatever reason. I have done quite a bit of turning with an 18 volt drill but the weight gave me some soreness in my wrists and that much power is not need for neck turning.

For big jobs (more than about 40 cases), I use my bench mounted drill press, with the Sinclair shellholders. RPM set as low as it will go, works fine.

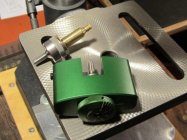

Attachments

jbpmidas

MR F-T/r

GSPV said:Get with Pbike here and get one of his neck turning motors.

Can you tell me any more about it?

jbpmidas

MR F-T/r

fdshuster said:For big jobs (more than about 40 cases), I use my bench mounted drill press, with the Sinclair shellholders. RPM set as low as it will go, works fine.

I've got a drill press. Hadn't thought about using it. That may be my cheapest option.

Lapua40X

California Hunter Education Instructor

fdshuster said:For big jobs (more than about 40 cases), I use my bench mounted drill press, with the Sinclair shellholders. RPM set as low as it will go, works fine.

I wouldn't have expected the shell holder to hold the case tight enough to prevent it from spinning at the base. Does that Sinclair shell holder truly hold the base tight enough to over come the friction drag of the cutter?

ridgeway

Silver $$ Contributor

Mine doesn't...I quit using it awhile ago. I use a K&M holder and it seems to work for the most part. I occasionally get one that likes to spin...that's when I insert a pin in the tightening hole for serious grip. I was thinking about trying a 21st Century case holder...its o-ring gripping design seems like it would work well. The price plus shipping is keeping from trying it...unless I hear a bunch of people swear by it.Lapua40X said:fdshuster said:For big jobs (more than about 40 cases), I use my bench mounted drill press, with the Sinclair shellholders. RPM set as low as it will go, works fine.

I wouldn't have expected the shell holder to hold the case tight enough to prevent it from spinning at the base. Does that Sinclair shell holder truly hold the base tight enough to over come the friction drag of the cutter?

Shuster, you just gave me another excuse to buy that drill press I've been wanting!

dannyjbiggs

Silver $$ Contributor

Lapua40X said:fdshuster said:For big jobs (more than about 40 cases), I use my bench mounted drill press, with the Sinclair shellholders. RPM set as low as it will go, works fine.

I wouldn't have expected the shell holder to hold the case tight enough to prevent it from spinning at the base. Does that Sinclair shell holder truly hold the base tight enough to over come the friction drag of the cutter?

Exceptionally well!!

Danny Biggs

Nodak7mm

Team Lefse

boogershooter said:Shuster, you just gave me another excuse to buy that drill press I've been wanting!

If your looking at benchtop drill presses, be sure to look at the RPM ranges... Most benchtop presses dont go slower than 600 rpm...

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.