Welp looked around the gun room and in the parts bucket a while back and saw I had enough parts to toss together a new upper without buying much new .

And decided to see what all the fuss was about when it came to the " new " .22 ARC....

And No the concept isn't new ..... Yes ,its roughly just a Sammi spec'ed .22 ppc/.22 coyote/.22 Grendel....y'all get the picture. Yeah you can make some arguments about shoulder angles and what not Hornady goes into a lot of details on there podcast.....but eghhhh.... Basically 6.5 grendel necked down to shoot heavy weight ..22 cal bullet out of a short action or mainly now an AR15.... I've built and played with the 6.5 Grendel , the 6mm Arc , so why not this lil dude ..... Alot of people also keep saying it's the closest thing you'll get to a 22-250 out of a SMALL FRAME so thought it would be neat to have both to compare.

Anyhow stuck at home so, just another one of my rambling lil posts for y'all who enjoy them .

So the core of this lil build is gonna be this 20" barrel from BCA ... They had a free shipping deal on all barrels so almost had too lol

Funny enough this is about the same barrel as my .22-250... Well except for the twist rate and chambering of course . But out the box it's .... Well it's a $100 barrel ,threads where a little gross and it doesn't seem to have all the oil and grease the last few I got had but hay

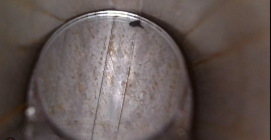

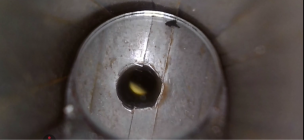

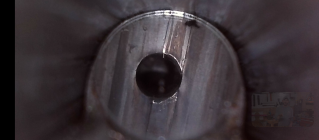

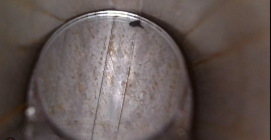

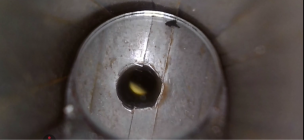

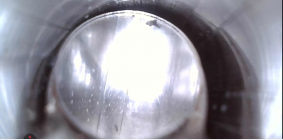

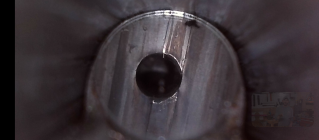

And what eveyone likes , some bore scope pics

Cron has a bit of a burr... Few rounds during function testing should take care of that

What looked like some surface rust

Slight burr on the gas port but not as bad as the .22-250.... Dull drill bit mabye ?

And the usual lead I've come to expect from BCA

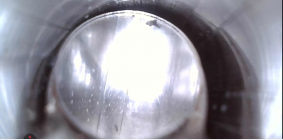

And cleaning . The rows left to right are wet patches of hoppes ,dry patches , patches with JB bore paste, short stroked all the way though the barrel , dry patches , hoppes wet patches ,dry patches , then two alcohol patches and imo cleaned up pretty good ,

Still has a few spots but 95% of the barrel is mirror like this so I'll say it cleaned up pretty good

So assembly time and I'm doing something a little different... Usually I'll grease the barrel extension to help it from locking up and becoming a pain to remove....buuut been reading and chatting with more and more " precision" AR builders and a lot of them will "bed " the barrels to the receiver in some way. I've seen thermo fitting where the upper is heated the barrel is cooled so they have a rock solid fit when they come to temp after assembling. I've seen one guy use a thin layer of JB weld on the extension and a crap load of release agent in the upper , kind alike how you do with a bedding job on a bolt gun. Some guys even just use nail polish..... Well apparently 620 green loctite is across the board agreed to be a pretty decent deal to use ..so

This upper is pretty tight so pretty sure I don't need this stuff but hay ... experiments ! And no one really says how much to use but you need to use a torch to get it off regardless so I just used a bush to give it a thin layer and spun the barrel as I put it in the upper to spread it out .. hopefully evenly.

And the usual AREO shell grease on the handguard threads

And since I don't have the torque settings for this handguard...and they can be anywhere from 30-80 lbs ...I just meet it kinda in the middle

As is my gas system. Bought this adjustable one from Grendel Hunter.com for my .22-250...but it runs great so it's just been sitting in the box lost the pin for the gas tube though so had to rob one off a old one I had

Aannnd done

Now ..for brass prep

I did a couple of ARs using this receiver facing tool. Both turned out very accurate. It's affordable, cheap, and easy.

AR Receiver Lapping Tool

I just watched your 22-250 videos. It makes me wonder sometimes because you get fairly good results with your techniques.

I did a couple of ARs using this receiver facing tool. Both turned out very accurate. It's affordable, cheap, and easy.

AR Receiver Lapping Tool

I just watched your 22-250 videos. It makes me wonder sometimes because you get fairly good results with your techniques.

Ya know I've been meaning to get one of these for the longest but always forget

honestly it would probably help some . If I was using grade A parts then probably not but with me using these random parts ...would probably help lol!

And thank you for watching ! Honestly means a lot when folks take time out there day to which me goof around lol

Aannnd some brass prep, so was thinking about buying some 6.5 Grendel and just converting it ..but egghh for the extra few bucks

And I don't have any factory ammo this time so gotta try and figure some stuff out... Mainly just need to see how much I need to resize the brass...but after doing a lil fit test with a life out the box.... If chambers with 0 resistance

.. I just fit a piece in the bolt and slide it in. Press the BCG in with my thumb till it clicks in place. Shouldn't take any real effort. If it does take effort or just won't go, it's too big and these are good out the bag

Still gonna full length resize just to be safe. Will come back to it after for forming

And next to a resize bit. Looks like it did work the neck some

Adid all those up the tossed them in the wet tumbler then in the toaster oven to dry... Now while I was doing that saw some of the 6.5 Grendel brass that's been on the bench for a while and thought....well why not ! And apparently your supposed to use Grendel brass and not 6ARC... Something about the shoulder angles

Anyhow all I've seen when it comes to 6.5grendel to 22 ARC is : get good lube , put lube on case , run case in .22 ARC die.... New .22 ARC case lol

So

And just what the step looks like

Aannnd nicer I had this lil buldger where the neck and should meet

Noticed my die and shell holer weren't touching so ran the die down some more

Much better

Did a fit check in the gun and went in with no hassle

And went ahead and made 10 of them... because... Reasons I guess lol

Also saw on the same tray I had some 7.62x39 ! And remember back in the day folks where converting 7.62x39 to Grendel sooo in my mind that mean I can convert it to .22 ARC.

So lube and straight to the .22 ARC ...aannnndd if I had some sense I'd seen this coming doing from a blown out .30 cal to .22 cal lol !

So used the Grendel die as a step down then went to the ARC and worked like a charm

Buuuttt

As you can see the shoulder needs to be blown out ..... Just a lil experiment more then anything

Anyhow was going to to start load testing today but took a few to meany melatonin and by the time I work up most of the day was gone so tomorrow it is... hopefully

I picked up a Stag from BKing, slightly more $ with the same idea (spare part build). Be interested on how yours shoots.

Okie dokie so got a lot of pic's but can only post 6 per post so work with me here lol.. also let's just say the first day was ...growing pains , new caliber, new gas system, I didn't think and do things like I usually do ...yeah was a bit of a cluster BUT... Live and learn ( and sorry I actually show my mistakes...not eveyone is perfect

) I guess ANYHOW !

So primed up with some.magtech 7 1/2 . My primer tool does have an adjustable depth setting but honestly I never messed with it I just try and get them all below flush

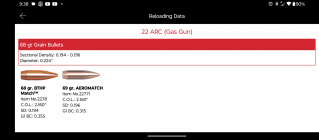

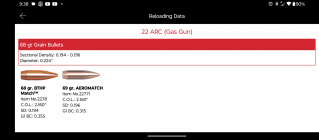

So as far as powder and load data gonna be running out of the Hornady 11th ( I got the phone app) and Going to be using some Leverevolution. One this is a Grendel based case and this stuff is supposed to be some of the best powder out there for Grendel and two , it has some of the most range for .22 ARC of about any other power . Both with bullet weights and velocity range per weight. O and I'm running gas gun data for a 68 gr bullet ... I'm using a 69 gr RMR but it should get me in the ball park ( I say all that and notice they have a 69gr Aero match with the 68gr BTHP......)

And it's a ball powder which ..I don't like but hay ...it's supposed to be great stuff so I'll give it a good try before I complain

And I'm using the next load from the start ..just because I don't think I've ever had a starting load shoot well and usually I'll need more gas it seems. Doesn't fill up a ton below the shoulder a bit

Now for some reason....unlike usually I didnt make a split case to find my jam.. usually I'll take a pice of brass cut the neck so I can slip a bullet in with a lil tension.. put that in the bolt chamber it and when the bullet hits the lands it will slide back in the case and bam, you know where you hit the rifling....well here I just kept adjusting the die till my round chambered without any real force. And our first five rounds

And with one of the 5.56/223 rounds I load with the same bullet

Also decided to give them all a crimp ..was trying to just give the a hair of a crimp but....yeahhh, but much and was tweaking them..but these are sighters so no biggie

So first few two rounds actually works just fine....at least from where I was sitting . Shot the first, boom slung the case about 4 O clock

Picked up the second shot it ,but..it felt off... Now what I couldn't see at the time was we started short stroking. BCG isn't coming back all the way to get the next round . Just enough to eject but not cycle

See the difference in the ejection from our first to our second ?

And this kept happening, and honestly I thought it was just the mag until

Yeahhh super dooper fun time

Anyhow some velocity and the bore sight target

Ok so I'm gonna keep it a buck with y'all...I'm kinda an idiot because for the next 15-20 Rd I just keep thinking it was the mag and then it was because wasn't giving it enough gas . See this is the first build that I purposely put an adjustable gas block in so I was just chocking it up to not knowing how to set it right so I kept adjusting while single feeding

Until I washed a few videos on how to tune these things ( I've watched them before but thought maybe I forgot something) had it all the way open and got this with he gas all the way open...at this point I knew something wasn't right

Aannnd then found. Out my seating depth was a hair too much after tying to eject a round and ...yeah.. worked fine when. I was putting the rounds in the bolt then testing ...but that's a bit different then how the rounds actually feed

Fun fun fun

And our 100yd target

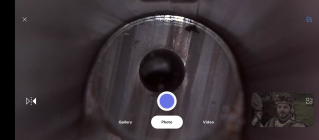

Went in cleaned her out readjusted the dies and at this point I'm kinda sick of this fancy adjustable block so stripped one the mil spec one off my Grendel and put it on . Made sure to use my bore scope to make sure it was aligned

So got her all aligned and tightened up.....BUT something didn't look right and as I looked a bit more ...Ends up the GAS port is drilled off center !

Well this is the stuff you get when you buy dirt cheap parts so egh...

Anyhow went out with the up dated rounds and ( also stopped crimping along with seating bullets deeper )

and boom no more short stroking !

And proceeded to single feed the rest by plopping one in and pushing it into the chamber with my pinky before sending it home. And that gave us

Well was running out of light but ran 15rd all with perfect last round lock backs so I wondered to my self if the problem was simply the gas block wasn't aligned.....if I had any good sense I would have checked that before I took it off but ...yeah never said I was the brightest light in the chandelier ... As a friend says lol... So I popped it back on and made sure it was aligned with the bore scope

And since it was getting dark and I didnt. Have a target up I just loaded up some of the converted brass

And just because I had to basically slip the handguard off every time to adjust the gas block I went and just took it off since I was going to just blast into the berm

So proceeded to the the standard gas block tuning deal and after two rounds boom got a order lock back !