Yes, those are typical 100 yd groupsAre all these targets shot at short range ?

--------------------

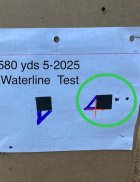

This would be the spread at longer range at 580 yds for a recent 2 shots per aim point waterline test

to adjust my load for 600

The line spacing on the binder paper is 1/4"

So about 3/4" spread there

--------------------

I was bumping my load up and was shooting high at first as you can see in the 3rd pic

Attachments

Last edited: