1.749" will not be an issue in terms of reloading your .223 Rem cases. They should grow longer over time with additional re-sizing/brass pre, so at some point you'll want to trim them. The 2.202" cartridge overall length (COAL) of the commercial ammunition you measured is a function of the particular bullet it has loaded, and what the manufacturer deemed to be optimal for that load. Commercial ammunition using different length/weight bullets can vary in terms of COAL, even from the same manufacturer. The 2.260" COAL value refers to the maximum length of loaded rounds that will feed from an unmodified magazine without issue. If you load rounds longer than that with an unmodified magazine, the bullet meplats may drag on the inside wall of the magazine and fail to feed properly.

FWIW - as described above, the 2.260" represents a

maximum COAL for loaded rounds so they can feed properly from a magazine. However, you don't have to load rounds to that maximum length. COAL for loaded rounds usually represents a compromise of the following two variables:

A) not being seated too far down in the neck, which causes the bullet base to unnecessarily occupy more case volume and can increase pressure for a given charge weight

B) maintaining a specific distance relationship of the bullet to the rifling in the barrel.

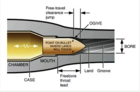

Most bullets will exhibit a strong preference in terms of optimum precision/accuracy when they are seated so that the point on the bullet ogive that first makes contact as the bullet enters the rifling is a specific distance away from touching the lands. A bullet seated any farther out in the neck such that it has actually entered the rifling is considered to be seated "into the lands" or jammed. A bullet seated just out of the lands is considered to be jumped.

Bullets in commercial ammunition are almost never seated into the rifling, or jammed, although reloaders can choose to do this on their own reloads if their is some advantage to precision in do so. Basically, you don't want the bullet seated way down in the case, occupying space that could be used for more powder. Nor do you generally want the bullet hanging so far out of the neck that it isn't solidly held in place by the neck tension (i.e. too little bullet bearing surface seated in the neck), but magazine length restrictions are normally shorter than that. So you want the bullet at a distance from touching the lands where it shoots well, but not sunk way down in the neck.

How can this compromise be made using very light (short) bullets for a given caliber, and those that are much longer (heavier)? The answer lies in a segment of the rifle chamber just in front of the end of the case neck that is referred to as the freebore, or lead. Basically, it's a section of the rifle bore where the nose of a bullet will fit when a round is chambered, but where the rifling hasn't started yet, so the bullet can freely move through it. By using reamers that cut different freebore lengths, shooters can literally choose what length (weight) bullets their rifle will be optimal for shooting by maintaining some specific distance (range) between a seated bullet and the start of the rifling. A picture is worth one thousand words, so I pinched the following image from 68forums.com, which shows very clearly the relationships I am trying to describe:

https://68forums.com/forums/showthr...ference-between-the-freebore-leade-and-throat

https://68forums.com/forums/showthr...ference-between-the-freebore-leade-and-throat

FWIW - I know there must be plenty of experienced shooters/reloaders in your neck of the woods. Having someone point out a few basics could make the process so much easier and more rewarding for someone just starting out. I would suggest posting a request here in the reloading forum to see if you can find someone in your area that can contact you directly. If so, it will make the learning curve much easier. Good luck with it!