Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

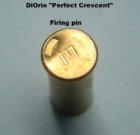

New Diorio Firing Pin

- Thread starter 1911nut

- Start date

Can’t modify a pin to make a footprint bigger. Probably have to machine a new pin to start, with a likely mod to the bolt nose, I’d guess.

Tommy, is this the pin that also incorporates “adjustable” ignition ?

I’ll see if PT&G will sell an unground pin.

garandman

Bolt Gun Bodacious

Logically....it seems a bigger "footprint" of the firing pin striking surface would be a good thing, in causing more reliable primer ignition, should there be a void / defect in primer compound inside the rim (tho I've had maybe 1-2 f-t-f in quality rimfire ammunition. Wondering if this pin is intended for match guns, or your $3-700 mass marketed 10/22s, 22/45's, Savages, etc

@1911nut .... I know what a "flier" is.... what's a "flipper"?

@1911nut .... I know what a "flier" is.... what's a "flipper"?

garandman

Bolt Gun Bodacious

Google search turnt up this....

http://www.wwaccuracy.com/showthread.php?5499-To-Bill-Calfee-I-have-received-my-new-DiOrio-Turbo-V-3

http://www.wwaccuracy.com/showthread.php?5499-To-Bill-Calfee-I-have-received-my-new-DiOrio-Turbo-V-3

garandman

Bolt Gun Bodacious

And this.... (read down a bit)

http://www.rimfireaccuracy.com/Foru...How-much-data-does-it-take-to-prove-something

http://www.rimfireaccuracy.com/Foru...How-much-data-does-it-take-to-prove-something

I’ll see if PT&G will sell an unground pin.

Be careful, My guess is this looks far wider than a simple unground pin, it appears double wide.

The new footprint seems to require more metal than is presently available.

Time will tell.

Be careful, My guess is this looks far wider than a simple unground pin, it appears double wide.

The new footprint seems to require more metal than is presently available.

Time will tell.

Yeah it looks like that. So my thought was now I have a vertical strike across the primer/rim. If the strike was horizontal across twice as much of the primer compound seems like more primer compound would be ignited.

Not exactly the DiOrio shape but maybe twice the primer contact and not wasted energy on the rim just by turning the striker 90 degrees.

Yeah it looks like that. So my thought was now I have a vertical strike across the primer/rim. If the strike was horizontal across twice as much of the primer compound seems like more primer compound would be ignited.

Not exactly the DiOrio shape but maybe twice the primer contact and not wasted energy on the rim just by turning the striker 90 degrees.

Well, some guys have autopsied rounds to find sometimes that the priming compound fractures and some gets misplaced so the “ more priming compound” deal makes sense.

That said, I got a call from a top RF smith that feels probably that footprint probably only requires pin mod, nothing else. If so that would be a plus.

I ordered a couple last year, seemed too short to try anything much different. Called them to ask if I could buy some not sharpened. No dice," take or send them back". I took my two broke ones and replaced the pins myself. Did not make any that resembled the one it the pic above. Made one round and another 1/2 moon.I’ll see if PT&G will sell an unground pin.

Disagree.

The additional impact force required to cause that much footprint to crimp deeply enough is enough to cause issues on it’s own.

A guy needs plenty of ignition, but 6 & 12 with conventional impact area sounds like a better option to me.

I’ll follow along to see if I am wrong.

The additional impact force required to cause that much footprint to crimp deeply enough is enough to cause issues on it’s own.

A guy needs plenty of ignition, but 6 & 12 with conventional impact area sounds like a better option to me.

I’ll follow along to see if I am wrong.

Hi-NV Shooter

Gold $$ Contributor

Disagree.

The additional impact force required to cause that much footprint to crimp deeply enough is enough to cause issues on it’s own.

A guy needs plenty of ignition, but 6 & 12 with conventional impact area sounds like a better option to me.

I’ll follow along to see if I am wrong.

Why would changing the impact orientation require a different force/spring rate? for example if I reground the pin tip to be on the horizontal plain why would it require more force to get the same impact as in this case sample

Why would changing the impact orientation require a different force/spring rate? for example if I reground the pin tip to be on the horizontal plain why would it require more force to get the same impact as in this case sample

View attachment 1134565

I don't think it is only an orientation change. It appears that the pin in the first photo has a lot more AREA under it than does a normal pin. Your pin above is pretty large.

Thus, my comment.

-Nate

Why would changing the impact orientation require a different force/spring rate? for example if I reground the pin tip to be on the horizontal plain why would it require more force to get the same impact as in this case sample

View attachment 1134565

The potential changes”may” require a spring rate change.

The fact that you now avoid the work hardened rim may require less, balanced with the larger overall strike, so some guys, no doubt, will play around.

We’ve seen way too many instances where over sprung is every bit as bad as under.

Some Clarification:

The new pin shape is available for all of our V series Turbo actions, no modifications to the existing bolt body are required to accept the new shape.

There are two options for those interested in obtaining the new pin profile. Option 1 - ship your existing firing pin slide assembly to our facility to have the pin tip replaced, Option 2 - purchase a new firing pin slide assembly.

I developed the new pin shape to address some inherent pin strike issues related to the traditional chisel shaped profiles. I am in the process of conducting several tests and additional information and results will be released once testing is completed.

If you have questions regarding this or any of our products please feel free to contact me via email @ anthony@dioriomfg.com

Best Regards, Anthony DiOrio

The new pin shape is available for all of our V series Turbo actions, no modifications to the existing bolt body are required to accept the new shape.

There are two options for those interested in obtaining the new pin profile. Option 1 - ship your existing firing pin slide assembly to our facility to have the pin tip replaced, Option 2 - purchase a new firing pin slide assembly.

I developed the new pin shape to address some inherent pin strike issues related to the traditional chisel shaped profiles. I am in the process of conducting several tests and additional information and results will be released once testing is completed.

If you have questions regarding this or any of our products please feel free to contact me via email @ anthony@dioriomfg.com

Best Regards, Anthony DiOrio

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.