You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nesieka RBLP Magnum to Standard Conversion

- Thread starter ricco1949

- Start date

Yes, I'll probably call Chad next week. I don't know if a longer sliding plate extractor is available if necessary.You might check with Chad at Long Rifles Inc. He use to work with Nesika actions.

Hal

Did similar years ago to a J with a cone bolt. Bought two bolts and opened one to a mag face. Ended up plugging the extractor plunger hole and relocating it to work with the mag diameter.

Alan

Alan

DaveTooley

Gold $$ Contributor

Is it coned or flat face? Flat face extractors aren't that hard to make.Yes, I'll probably call Chad next week. I don't know if a longer sliding plate extractor is available if necessary.

It's a coned bolt. I may try making one before going Alan's route above.Is it coned or flat face? Flat face extractors aren't that hard to make.

Clamping for the angled extractor cut looks like a challenge for a self taught wanna-be though.

Thanks for the advice.

Last edited:

Did similar years ago to a J with a cone bolt. Bought two bolts and opened one to a mag face. Ended up plugging the extractor plunger hole and relocating it to work with the mag diameter.

Alan

What did you use to plug the original plunger hole? Epoxy or solder?

Thanks for the advice.

DaveTooley

Gold $$ Contributor

I have a bunch of extractors. Most I don't know what they fit. Get me a couple of measurements.It's a coned bolt. I may try making one before going Alan's route above.

Clamping for the angled extractor cut looks like a challenge for a self taught wanna-be though.

Thanks for the advice.

Width of the slot, upper and lower.

Thickness of the T section that slides under the slot.

That will narrow it down quickly.

Rather than cut up a good action, I would take the opportunity to build a new rifle.

Not cutting action or bolt. Simply soldering in a ring in bolt nose that could be removed later to reconvert to magnum.Rather than cut up a good action, I would take the opportunity to build a new rifle.

Be nice if I could find a .308 bolt only for a Model K.

Last edited:

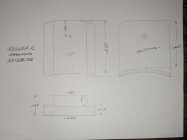

Nice job on the drawing.Thanks for looking Dave.

View attachment 1675405

Thanks...10th grade engineering drawing was a distant 60 years ago....I'm a little rusty.Nice job on the drawing.

DaveTooley

Gold $$ Contributor

Sorry all of mine are larger.Thanks...10th grade engineering drawing was a distant 60 years ago....I'm a little rusty.

This is how I've made some in the past. You'll make them two at a time.

Round stock- turn the OD and ID to the diameters you need.

Setup vertically in a mill and make the four cuts needed to get the inverted T.

I then cut them off with a jewelers saw leaving the wide T section long. Easy to mill this to the correct number.

Then worry in the claw part. Rotate the mill head or use an adjustable square to get the angle close for the lip.

Drill hole for the retaining pin.

Grind chamfer on the lip to allow the case to push the extractor back.

easy peezy

Then get part #2 and repeat knowing much more you now know than when you first started.

Last edited:

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.