222Jim

Silver $$ Contributor

Folks,

As fall approaches and I review my results (which I'm happy with, but we all know we can do better), I'm beginning to ponder how I select the bushing and mandrel size I use (trying) to set neck tension. Your feedback and thoughts would be appreciated.

Here's the situation. After I've fired my .22-250, the case neck outer diameter (OD) is 0.2520". Given it's a (i) 0.2240" diameter bullet, (ii) I want 0.0020" of neck tension, (iii) the neck wall thickness is 0.0130, and (iv) I'm assuming 0.0010" of spring back, I use a 0.2470" bushing die to compress the neck, i.e. 0.2240 - 0.0020 + 0.0130 + 0.0130 - 0.0010 = 0.2470". That gives me a 0.2210" ID before spring back.

I then use a 0.2220 mandrel die to stretch open the case mouth, thereby (hopefully) easing out any wall thickness variations before seating the bullet.

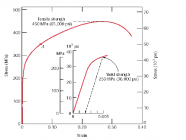

My query is, given the fact that final "mandrel sizing" is within the elastic deformation range for brass, is the brass simply going to return to where it was once I extract the mandrel? And if so, shouldn't I be using a smaller ID bushing die before inserting the mandrel so as to get the expansion closer to or just in the plastic deformation range for brass?

Thanks

Jim

As fall approaches and I review my results (which I'm happy with, but we all know we can do better), I'm beginning to ponder how I select the bushing and mandrel size I use (trying) to set neck tension. Your feedback and thoughts would be appreciated.

Here's the situation. After I've fired my .22-250, the case neck outer diameter (OD) is 0.2520". Given it's a (i) 0.2240" diameter bullet, (ii) I want 0.0020" of neck tension, (iii) the neck wall thickness is 0.0130, and (iv) I'm assuming 0.0010" of spring back, I use a 0.2470" bushing die to compress the neck, i.e. 0.2240 - 0.0020 + 0.0130 + 0.0130 - 0.0010 = 0.2470". That gives me a 0.2210" ID before spring back.

I then use a 0.2220 mandrel die to stretch open the case mouth, thereby (hopefully) easing out any wall thickness variations before seating the bullet.

My query is, given the fact that final "mandrel sizing" is within the elastic deformation range for brass, is the brass simply going to return to where it was once I extract the mandrel? And if so, shouldn't I be using a smaller ID bushing die before inserting the mandrel so as to get the expansion closer to or just in the plastic deformation range for brass?

Thanks

Jim