lcx99321

Silver $$ Contributor

I saw a video from Primal Rights where he talked about running tight neck tension and moving a large amount of material during case prep. The idea was that it helps smooth out imperfections in the brass. It made sense to me, so I gave it a shot. At first, it worked great—groups were solid.

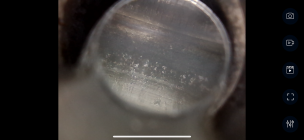

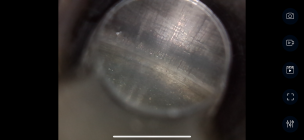

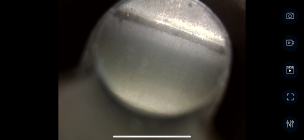

But then I started noticing my brass was getting shorter with each firing—0.002” shorter every firing. Shoulder measurement hasn’t changed across the 3 firings. and it’s super consistent across the whole batch. By the third firing, case length was down to 1.8995”, and I started seeing some nasty carbon buildup around the throat area (I think that’s the right term—the little gap just in front of the case neck in the chamber).

Now my groups are going to crap. It still shoots tight for the most part, but I get a random flyer in almost every 3-shot group. The barrel has about 1,000 rounds through it, which seems a little early for the barrel to burn out.

So here’s what I’m trying to figure out:

Thanks in advance for any input!

But then I started noticing my brass was getting shorter with each firing—0.002” shorter every firing. Shoulder measurement hasn’t changed across the 3 firings. and it’s super consistent across the whole batch. By the third firing, case length was down to 1.8995”, and I started seeing some nasty carbon buildup around the throat area (I think that’s the right term—the little gap just in front of the case neck in the chamber).

Now my groups are going to crap. It still shoots tight for the most part, but I get a random flyer in almost every 3-shot group. The barrel has about 1,000 rounds through it, which seems a little early for the barrel to burn out.

So here’s what I’m trying to figure out:

- Why is my brass shrinking? Could it be a donut forming? If I’m using an expander mandrel, it shouldn't be a problem to affect groups?

- Are the flyers coming from the carbon buildup, or is the donut the real problem?

- 25 Creedmoor, Lapua 6.5 CM brass

- H4350, 39.2 gr

- CCI 450 primers

- 2780 fps

- SD around 4–6, ES about 12–15

- Berger 135gr LRHT, seated 0.020” off the lands

- Anneal every firing

- Loading on a Dillon 550

- Full length sizing with a Whidden bushing die

- .276 bushing followed by a .254 expander mandrel

Thanks in advance for any input!