Bruce Thom's complete response

Bruce gave me permission to post his responses. Here is our complete conversation. He gave very thorough answers, but then accused me of complaining by taking it to the forums. He must not have noticed the dates on the posts or emails, nor the fact that I TOLD him in the first message that I was posting on accurate shooter. I was just asking questions and trying to be as thorough as he was.

Ron

From: Ron Goodger [mailto:lrgoodger@gmail.com]

Sent: Monday, September 03, 2012 6:02 PM

To: batmachine@earthlink.net

Subject: lugs galling

Sirs,

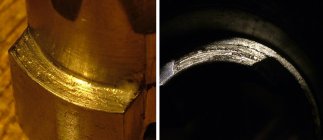

I purchased a BAT MB action (serial number MB284) from Bruno Shooters back in May and I have a problem with it. I have been very happy with the action until now because it has been winning match after match for me. The action has about 1400 rounds on it now and at about 900 rounds I noticed the bolt lugs were starting to gall. I clean and lube the bolt (and gun) every 50 rounds, so I started applying extra grease to the lugs in the hope that it wouldn't get any worse, but it did anyway. Please find attached photos of two of the four surfaces.

I posted a question about this on accurate-shooter and the consensus seems to be that the Tetra gun grease my local reloading supplies gunshop recommended is inadequate. That may be, but I'm surprised that the metal galled in spite of regular lubrication.

My limited understanding of gunsmithing is that if these surfaces are cleaned up by re-cutting them, that will mean setting back both barrels I use with the action to adjust headspace. That seems like an expensive proposition. The action still cycles fine and accuracy seems to be un-affected, so I'm wondering if there is some other solution to this issue. Will the galling stay as it is if I just start using the proper lube, or will it continue to get worse anyway? If I return the action to you at the end of October when the shooting season is over, can you fix this? What is your recommendation?

I am planning to get Montana X-Treme gun grease for future use. Will that be adequate?

It would have been nice to have gotten some paperwork with the action that explained necessary precautions needed to prevent galling if it is a known issue with stainless.

Best regards,

Ron

-----Original Message-----

From: Bruce Thom [mailto:batmachine@earthlink.net]

Sent: Monday, September 03, 2012 10:37 PM

To: 'Ron Goodger'

Subject: RE: lugs galling

Ron

Once galling starts it compounds itself and gets worse.

As soon as you see ANY galling it needs to be taken care of or you will have the mess you now see.

As the lugs have 100% contact when they leave here the lug grease really has no place to stay as you close the bolt it wipes itself off.

I obviously have many rifles built on my actions – and have had them for years and many have wore out multiple barrels.

The ONLY time I have ever started to gall lugs was when I let my brass get snug and kept shooting it that way because I did not have time to make new brass. This has only happened to me on two of my actions and I cleaned them up immediately at the match with some careful stoning and then lapped the lugs with JB and have not had any problems since then.

My recommendation to all users of any action that is made with 100% lug contact including trued up Remington’s is to make sure you do not close your bolt on tight cases, or you will gall the lugs. I also recommend after cleaning the bolt and lubing the lugs, that you close the bolt with the trigger held back so that you can actually get the grease all the way across the lugs instead of wiping it off the first time you close the bolt.

Our stainless actions use a chrome moly bolt body, so it is not stainless on stainless. I have looked at many Kelby actions, and trued remingtons, that are galled up just like yours and the lugs on their actions are chrome moly in the receiver and the bolt – so galling is not exclusive to stainless body actions.

As far as the grease we recommend – which I am pretty sure we still include in every action shipped( I do not do the shipping anymore) – but it may not have made it to you from Bruno, we have had the best results with a products called Miltec. Send me your address and we can send you some.

As far as fixing your action I am afraid we would have to do exactly as you described. The whole surface of both bolt and receiver is galled – as you can see from your pictures – good job by the way on the pictures, not easy to get a good picture down in the receiver!

I can keep the headspace very close to what it was (.001 or less) by dusting the face of the action where the barrel tenon seats, the same amount that comes off the lugs. So setting your barrels back would not be needed. New brass might be needed if I end up on the tight side.

I doubt the grease you were using contributed to the galling – I have used many types and they all work. The stuff we recommend now is just less messy, and does not pick up dirt as much and seems to actually get into the metal and stay there longer. I would say either snug cases or a bit of dirt or powder residue dropped in there and started a small gall, and it just compounded it self from there.

Regards,

Bruce Thom

From: Ron Goodger [mailto:lrgoodger@gmail.com]

Sent: Tuesday, September 04, 2012 5:49 PM

To: 'Bruce Thom'

Subject: RE: lugs galling

Bruce,

I appreciate your prompt and thorough response more than you know.

I find it interesting that you place so much emphasis on snug brass. This MB action started life with the 6BR paririe dog barrel on it in early June and I ran 600 rounds of new Lapua brass through that barrel during load development and the hunt. I know none of it was loaded more than twice. When I got home from the hunt I screwed the 6BR barrel off and put on the 30BR barrel for a summer of competitions. It just so happens that I normally neck size only until the brass gets tight, but in this case I full length resized from the start, so I KNOW there has never been tight brass run through this action.

Ironically, I've been running tight brass through the only other custom action I have (not a BAT) for 3400 rounds and it is showing no signs of galling. I shall cease that practice immediately, however, because what you say is sound from a physics standpoint.

I understand the galling compounding itself. It's kind of like burs on a crankshaft journal. Pits don't hurt the bearings - the burs do. I'm thinking I need to hit the high points on the galled surfaces just enough to take the sharp edges off without changing headspace. That should get me through the season, and then I can send you the action for repair.

I really don't have a clue what caused this issue, although there was one windy day in Wyoming when there was fine sand in the air and it did get in the action. I had to stop shooting and clean it when I felt the bolt tightening up. The first signs of galling did not show up for at least 800 rounds AFTER that, so I doubt that was the root cause. I always inspected and lubed the lugs when I cleaned, and it was fine for a long, long time after Wyoming.

What would be the cost of getting this fixed when I send in the action?

Ron

BTW, thanks for the compliments on the photos. It did take a while and several tries to get the receiver shot. Here is the address for the bolt grease.

Ron Goodger

(redacted)

(redacted)

-----Original Message-----

From: Bruce Thom [mailto:batmachine@earthlink.net]

Sent: Wednesday, September 05, 2012 10:53 AM

To: 'Ron Goodger'

Subject: RE: lugs galling

Ron

The reason I place emphasis on snug brass is that has been my personal experience.

The cost for cleaning it up will be $150.00

Regards,

Bruce Thom

From: Ron Goodger [mailto:lrgoodger@gmail.com]

Sent: Monday, September 10, 2012 3:58 PM

To: 'Bruce Thom'

Subject: RE: lugs galling

Bruce,

What are the Rockwell hardness figures for the bolt and the receiver? Do you order the stock pre-hardened (if so, do you check every shipment or just spot check), or do you have it hardened after the pieces are cut?

Perhaps something slipped through.

Ron

-----Original Message-----

From: Bruce Thom [mailto:batmachine@earthlink.net]

Sent: Tuesday, September 11, 2012 1:39 PM

To: 'Ron Goodger'

Subject: RE: lugs galling

Bolts are 43 to 46 rc – after we rough turn, the blanks are heat treated, certified by the heat treater and then we check them in our shop to verify.

Receiver bodies are 36 to 38 Rc, heat treated in our shop and tested.

NOTHING slips thru heat treat testing. If the heat treating is not done properly the action will not be safe to use, which is our first concern. The hardness we have selected are based on maximizing the materials toughness and creating a hardness difference between them to minimize galling tendencies.

It seems you would like to find a reason other than tight cases, or dirt or lack of maintenance for your galling.

Stainless steel receiver bodies are not really the best choice for building an action that will not have at least some tendency to gall. Stainless in itself has tendency to gall due to the high chrome and nickel content. 17-4 is one of the better stainless steels to resist galling, but it still has that tendency.

We did not just start building actions yesterday and we did a lot of research when we started building actions 18 + years ago. For what people want – stainless steel - there are not a lot of options to improve the situation. There are some extremely expensive and difficult to machine stainless steels – actually they are not classed as stainless, they are called heat resistant alloys. Between the cost and the difficulty of machining these the actions cost would increase at least 75% more, and the possibility of galling would not be completely eliminated.

If you want to eliminate galling then you have to be willing to have a nitrided action and it is going to be black and cost you $100.00 more.

A small – very small improvement can be had over stainless by ordering a chrome moly receiver body instead of stainless – again it will be blued.

If you would like to have your receiver nitrided when you send it back too clean it up we can do that. The cost is $100.00 for nitriding. If you use your rifle in dirty conditions where you do not have the opportunity to clean it I would recommend this.

I see you have now taken your complaints to the forums, feel free to copy verbatim anything I told you in these emails – in its entirety – do not pick and choose sentences if you are going to post it. I would prefer the info be shared for others benefit.

Regards,

Bruce Thom