You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looks like the AMP Annealer will have some competition soon

- Thread starter stavey

- Start date

Larry Koch

Silver $$ Contributor

This might explain the 200.00 off of the amp today?

It should also make a good latte ...Now if this annealer had a little conveyer belt on the top that auto dropped in the brass, amp would be up for sale

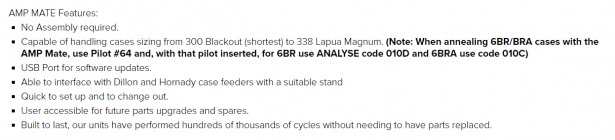

Amp themselves state on their website that their amp mate isn’t compatible with br/bra cases.

I missed that statement - I guess mine is broken…

Dillon Feeder + AmpMate + AMP = effortless, high volume, precise annealing.

mfendley

Gold $$ Contributor

I don't own an AMP. Won't pay their price to heat a piece of brass, and I am still not convinced that it does any better of a job than a good flame annealing process. Annealing = time @ temperature. Nothing more.

If I had paid the money for an AMP I would defend my decision with a passion in order to keep from feeling foolish for spending so much money.

I do think the AMP is a great piece of equipment. so is an Annie. Certainly different price points.

Nice to see some competition. I look forward to the battle to come. It can only benefit us as users.

If I had paid the money for an AMP I would defend my decision with a passion in order to keep from feeling foolish for spending so much money.

I do think the AMP is a great piece of equipment. so is an Annie. Certainly different price points.

Nice to see some competition. I look forward to the battle to come. It can only benefit us as users.

I am using the Quick Anneal for over 2 years now. I switched from flame to induction for consistent annealing and speed. I don't believe you need the scientific AMP to get consistent neck tension release, but others do- get the AMP then its a great machine. But everyone has his own OCD issues.. annealing is not mine! Testing usually eliminate allot of questions!!I don't own an AMP. Won't pay their price to heat a piece of brass, and I am still not convinced that it does any better of a job than a good flame annealing process. Annealing = time @ temperature. Nothing more.

If I had paid the money for an AMP I would defend my decision with a passion in order to keep from feeling foolish for spending so much money.

I do think the AMP is a great piece of equipment. so is an Annie. Certainly different price points.

Nice to see some competition. I look forward to the battle to come. It can only benefit us as users.

Last edited:

I wish my AmpMate was effortless. I've owned mine for nearly 3 years, spoken with Matt and Alex numerous times, it never works 100%. Always gets hung up on something. Even replaced it with a new one, same situation. I anneal faster with 2 brass holders.I missed that statement - I guess mine is broken…

Dillon Feeder + AmpMate + AMP = effortless, high volume, precise annealing.

Preacher

Gold $$ Contributor

I've had a bunch of annealers of different makes, and they all did pretty darn good, But a PITA when lots of times I only need to anneal 6 cases a bunch of times during the day, and it sure is easy to poke a few buttons on the AMP instead of dealing within the time consuming setup of the others..

I never took the time to see where this new one is made

A major factor for me personally in not buying an amp is where it’s made. I understand New Zealand?

Didn’t Barnard actions go away? Maybe I don’t have my facts straight. We need American shit. Harder to regulate away with importation restrictions.

A major factor for me personally in not buying an amp is where it’s made. I understand New Zealand?

Didn’t Barnard actions go away? Maybe I don’t have my facts straight. We need American shit. Harder to regulate away with importation restrictions.

True, but what about export restrictions, product liability, constantly moving regulations, etc. Made in USA = Liability. Until we take our government back and elect representatives who may have an actual understanding of our founding principals, I personally would never get involved as a manufacturer or even as a direct importer of record.We need American shit. Harder to regulate away with importation restrictions.

That’s what I meant in a round about way.True, but what about export restrictions, product liability, constantly moving regulations, etc. Made in USA = Liability. Until we take our government back and elect representatives who may have an actual understanding of our founding principals, I personally would never get involved as a manufacturer or even as a direct importer of record.

searcher

Gold $$ Contributor

I don't know what the true capabilities are of the "quick anneal". I haven't used it, so I cannot form any opinion on it other than what I read. When I bought my Amp, I segregated 1,000 pieces of .20 Practical brass into about 4 different weight groups and "burned" a case from each group to come up with the annealing setting using the Aztec program. And it did give me unique settings for each group (which were about 5 to 6 tenths of a grain apart in weight). I was curious as to whether those would be repeated as accurate when I "burned' another case from each group, just to see. The results were almost identical. I was pretty impressed. There is little doubt in my mind that if one threw in a case from another manufacturer that differed in composition or weight - it would signal a different code- so I'd say it does find such anomalies between cases. But you would have to "burn" the case to find out - or use their recommended codes instead for that brand in caliber. I was using all Lake City brass, though mixed years. It seemed the brass metallurgy was close enough between the different years of brass to not create a different code, yet weight definitely did matter in this little "test".From their accomplishments overseas it appears they have already proven themselves. They have been around for years. As far as the Aztec software goes the sensors in the quick anneal do the same thing by adjusting heating temp and time . It just doesn’t burn up a case or charge extra for the software. The quick anneal can also detect when a different brand is mixed in or when there is an anomaly with the neck thickness. I don’t believe the AMP has the technology to do either of those things. Not to mention it works with any variable speed case feeder. For $990 shipped and you don’t need seperate pilots. As I’ve said competition is always good for the consumer.

In the instructions, they give codes for various manufacturers of brass in each caliber - and different codes for specific years of the same brass for the same caliber in a few situations - at least one being for Lapua brass. So - they are even telling us to expect different codes for the brand of brass that is universally accepted as the most consistent brass out there - depending on whether it is a specified year. Pretty accurate brass assessment in my mind.

That said, if the other machine can analyze each piece, regardless of make and weight, and automatically anneal them to be the same, I'd say that is the pinnacle of annealing. I think the question is whether that is what is really happening. After all, it could take a lot of shooting to see whether that is happening as advertised. Back to other tests for extraction or seating pressures to ascertain?

Last edited:

I never took the time to see where this new one is made

A major factor for me personally in not buying an amp is where it’s made. I understand New Zealand?

Didn’t Barnard actions go away? Maybe I don’t have my facts straight. We need American shit. Harder to regulate away with importation restrictions.

Made in South Africa

Yeah see I can’t help but wonder if it’s a bad idea to spend a bunch of money on a tool made in a gun-unfriendly country same as New Zealand if you ever need support down the road.Made in South Africa

stavey

Silver $$ Contributor

I thought that the test function was quick annealer version of Aztec . It is not . Their machine is setup by watching for a glow and setting a timer. While this is consistent. Without a hardness tester you won’t know if your consistency is in the 90-105 window. Where it should be. Just something else to think about . Here was their response when I emailed them on how to set their machine up.

Similar threads

- Replies

- 8

- Views

- 942

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.