I found that I definitely have gotten the most consistent readings on seating pressures using this product. Which would indicate to me, that I am getting consistent neck tension. I do turn my brass also. I’ve been testing and testing trying to achieve the most consistent neck tensions I can through the use of neck turning, mandrels and lubricants. Thus far, this product has worked the best for me.

Youre doing all the good work and the results show. Great job.

Scott Wills

Silver $$ Contributor

Youre doing all the good work and the results show. Great job.

Thanks. I spoke at length to Pete Petros at 21st Century about the lubricant issue. He told me that for years, he was recommending Neolube. Then he added, that their testing, found the new moly product to be better, in their opinion. To his credit, he never tried to shove his product down my throat, or in any way bash Neolube. He told me that they are both great products. I have found that I do like their moly product better. I apply before, I use the mandrel, then again before seating to make certain I’m getting consistent coverage for seating.

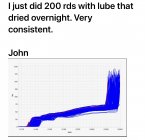

Hi Guys I'm Sandro and I recently proposed to Pete from 21 century a new Lube which is giving excellent results both for the Expander Die passage and for neck turning. It is not greasy because it is based on water and Htech polymers, it dries with a finger after turning the neck, a drop on the neck and one on the Pilot is enough to have an excellent job. Just leave it to dry upside down for 4/8 hours depending on whether the environment is dry or humid and move on to the usual recharge. It should not be washed out like normal oil because it leaves an imperceptible film of polymers inside the neck which favors the assembly of the ammunition with a constant and low pressure. Evaluations made with AMP press and also evaluated by Fclass John during his videos. For the expander step, all you need to do is put a few drops of NoOilLube in a small beer cap, immerse the neck and you will have a small bubble at the top, transparent like soap bubbles. Pass the expander and you will see the shiny interior without scratches or other damage, normal with dry cleaning. Those who don't like this practice can use foam sticks on sale on Amazon to pass the Lube inside the neck and leave it to dry upside down to avoid any excess ending up in the Primer pocket. I leave you to your discussions which I follow with interest. I attach some photos and also the graph obtained by Fclass John with 200 bullets inserted with AMP press. The product is already available at 21 century…. Best regards

Sandro CEO of

Delta Carbon Precision

-

IMG_1051.jpeg

1.3 MB

· Views: 98

-

D99E339A-26BA-429E-AA0C-BED7D41825A2.jpeg

359 KB

· Views: 85

-

IMG_1048.jpeg

409.3 KB

· Views: 85

-

IMG_0681.jpeg

809.2 KB

· Views: 72

-

bc4d0598-9114-4c4d-9fbb-21a35a9177dd.jpeg

72.5 KB

· Views: 73

-

IMG_6422.jpeg

182.1 KB

· Views: 92

F-Class Shooter (6BRA and WIN 284)

I stand up cases on baking sheet and spray with Hornady One-Shot at a 45 degree angle from both directions. Once I have sized and expanded the necks, I just tumble in corcob for 30 minutes to revoe the lube. Easy button.

Mark Niezabitowski A tuner whisperer

Gold $$ Contributor

Delta carbon have you considered becoming a site sponsor yet ?

F-Class Shooter (6BRA and WIN 284)

Hi Guys I'm Sandro and I recently proposed to Pete from 21 century a new Lube which is giving excellent results both for the Expander Die passage and for neck turning. It is not greasy because it is based on water and Htech polymers, it dries with a finger after turning the neck, a drop on the neck and one on the Pilot is enough to have an excellent job. Just leave it to dry upside down for 4/8 hours depending on whether the environment is dry or humid and move on to the usual recharge. It should not be washed out like normal oil because it leaves an imperceptible film of polymers inside the neck which favors the assembly of the ammunition with a constant and low pressure. Evaluations made with AMP press and also evaluated by Fclass John during his videos. For the expander step, all you need to do is put a few drops of NoOilLube in a small beer cap, immerse the neck and you will have a small bubble at the top, transparent like soap bubbles. Pass the expander and you will see the shiny interior without scratches or other damage, normal with dry cleaning. Those who don't like this practice can use foam sticks on sale on Amazon to pass the Lube inside the neck and leave it to dry upside down to avoid any excess ending up in the Primer pocket. I leave you to your discussions which I follow with interest. I attach some photos and also the graph obtained by Fclass John with 200 bullets inserted with AMP press. The product is already available at 21 century…. Best regards

Sandro CEO of

Delta Carbon Precision

The issue is that the cost of this lube from 21st century is $40 shipped. If you could make it more affordable I think it would be a winner.

The issue is that the cost of this lube from 21st century is $40 shipped. If you could make it more affordable I think it would be a winner.

hi..I imagine the difficulty is the same that we encounter in producing it. With two wars on our doorstep after the post-Covid period, Europe has gone crazy, and even some suppliers have gone bankrupt. Only the Chinese with their poorly controlled stuff hold up. Little money equals unreliable material... with us Powder cases and Berger Bullets cost you a fortune and it's not even easy to find them in the shop.... sorry for the comparison

hi..I imagine the difficulty is the same that we encounter in producing it. With two wars on our doorstep after the post-Covid period, Europe has gone crazy, and even some suppliers have gone bankrupt. Only the Chinese with their poorly controlled stuff hold up. Little money equals unreliable material... with us Powder cases and Berger Bullets cost you a fortune and it's not even easy to find them in the shop.... sorry for the comparison

Are you the guys that make the roll up mirage shield?

Hornady One Shot Case Lube has been working great, resulting in single digit SDs and excellent accuracy. I first tried RCBS dry lube but it seemed very little stuck to the insides of the necks. Then I tried 21st Century Moly powder w/ceramic beads, same thing, it looks like very little sticks, I can feel friction when seating, and the moly has to be wiped off with a rag.

When I apply Hornady with a Qtip, both mandrel and bullet seating feel glass smooth and consistent. It's faster and cleaner, and according to my Garmin chronograph just as effective. Maybe someone with better electronics can quantify the difference.

Delta carbon have you considered becoming a site sponsor yet ?

I'm sorry but I'm in Italy and English is not my native language either. I have no idea about the sponsor of the site because I am very small and I use the proceeds from sales to sponsor the races. But I think it could be an interesting opportunity…. I'll go look for information... thanks for the advice

Are you the guys that make the roll up mirage shield?

yess i am … Sandro of Delta Carbon Precision

-

IMG_9794.jpeg

536.1 KB

· Views: 60

-

IMG_6649.jpeg

166.1 KB

· Views: 53

-

IMG_6642.jpeg

334 KB

· Views: 52

-

DBE046A9-FF31-42CF-884E-D49B7CAB1674.jpeg

337.7 KB

· Views: 59

-

IMG_4560.jpeg

291.7 KB

· Views: 63

The OP's post states, "for bullet seating".

I can understand lubing the inside of the neck for sizing, especially when using an expander ball on a conventional FL die. But why would you lube the inside of the neck for seating a bullet???

I have loaded literally thousands of rifle and pistol rounds and never had any problem seating bullets. I do nylon brush the inside of the necks as part of prep for sizing but have never lubed the inside of the necks to seat a bullet. Just curious as to what that is supposed to achieve.

Hornady One Shot Case Lube has been working great, resulting in single digit SDs and excellent accuracy. I first tried RCBS dry lube but it seemed very little stuck to the insides of the necks. Then I tried 21st Century Moly powder w/ceramic beads, same thing, it looks like very little sticks, I can feel friction when seating, and the moly has to be wiped off with a rag.

When I apply Hornady with a Qtip, both mandrel and bullet seating feel glass smooth and consistent. It's faster and cleaner, and according to my Garmin chronograph just as effective. Maybe someone with better electronics can quantify the difference.

I haven't had the chance to try the Lube Hornady spray but I think it's definitely worth it. The Delta No OIL Lube is a valid competitor as it is not a water-based spray nor is one drop on the spindle Pilot and one on the neck enough to turn and one pack is enough to process more than 400 Brass. For the expander the die lubricates well and the film released once dry has very low and constant SDs both in F/tr and in Open in 2.6fps (0.8 mts metric). Certainly the data obtained with the AMP press have given excellent results and this Lube is rapidly gaining ground and success among shooters in many continents, even among the most skeptical. It has been defined as an excellent alternative, also for pointing where it favors the non-greasy approach of the apex of the bullet in the press and for the processing of the primer pocket. Just use it in moderation, not as ketchup on chips, and let it dry well. I can define it as a non-oily, non-greasy Lube that lubricates and does not dirty the tools, workbench and hands. It dries for the right amount of time if you lubricate the inside of the neck either with an expander pass or with foam sticks. It does not leave sticky residue after Annealing and does not contain graphite that remains in the barrel after the shot. To try ..? I think so

I haven't had the chance to try the Lube Hornady spray but I think it's definitely worth it. The Delta No OIL Lube is a valid competitor as it is not a water-based spray nor is one drop on the spindle Pilot and one on the neck enough to turn and one pack is enough to process more than 400 Brass. For the expander the die lubricates well and the film released once dry has very low and constant SDs both in F/tr and in Open in 2.6fps (0.8 mts metric). Certainly the data obtained with the AMP press have given excellent results and this Lube is rapidly gaining ground and success among shooters in many continents, even among the most skeptical. It has been defined as an excellent alternative, also for pointing where it favors the non-greasy approach of the apex of the bullet in the press and for the processing of the primer pocket. Just use it in moderation, not as ketchup on chips, and let it dry well. I can define it as a non-oily, non-greasy Lube that lubricates and does not dirty the tools, workbench and hands. It dries for the right amount of time if you lubricate the inside of the neck either with an expander pass or with foam sticks. It does not leave sticky residue after Annealing and does not contain graphite that remains in the barrel after the shot. To try ..? I think so

The OP's post states, "for bullet seating".

I can understand lubing the inside of the neck for sizing, especially when using an expander ball on a conventional FL die. But why would you lube the inside of the neck for seating a bullet???

I have loaded literally thousands of rifle and pistol rounds and never had any problem seating bullets. I do nylon brush the inside of the necks as part of prep for sizing but have never lubed the inside of the necks to seat a bullet. Just curious as to what that is supposed to achieve.

Surely the non-greasy and effective dry lubrication already avoids scratches and tears inside the neck inevitably left by a dry Expander. It avoids polishing work with steel wool abrasive pastes and anything else that comes into the Shooter's imagination. Sometimes the tests also prevail over the results, how many people like tinkering more than concentrating on mirages and flags blown by the wind?!

It is inevitable that a closed ammunition with a constant insertion pressure gives the same result on the sign, limiting how many vertical flyers possible and reducing the horizontal ones, wind always permitting. So for me the advantages are there, even if a low SD is not a guaranteed victory as the weak link in the system is always us shooters with our minds and emotions during the race...

I've had good luck with a Q-tip and Imperial dry neck lube. Not messy and gives consistent neck tension.

Just dip the base of the bullet in the applicator of the redding dry lube kit- no mess or waste on the outside of the neck and no need to waste and fret with q-tips