x 10Im a bit worn out on this topic for now.

Way into the weeds...

x 10Im a bit worn out on this topic for now.

You can sell that lathe and find one more suited to barrel work. Dont try to fight it with workarounds, youll never be happy trying to learn and making workaround jury rigs at the same time

Remember the bore has to be big enough to press in a sleeve thats thick enough to be solid and still be big enough inside. Youll be looking for like a 4” roller bearingBoyd

Thanks for posting those pictures. I would like to make one of those rest

if I could find the right bearings.

I'll have to do more searching.

Hal

Google Pillow Block bearings.Boyd

Thanks for posting those pictures. I would like to make one of those rest

if I could find the right bearings.

I'll have to do more searching.

Hal

Just run it in the steady... No fancy gizmos needed. Another idea...just machine a heavy wall tube, drill and tap for 4 set screws and mount it in your steady rest. Got your cat head that runs in your steady. Many ways to do it, just a little thought...

Just run it in the steady... No fancy gizmos needed. Another idea...just machine a heavy wall tube, drill and tap for 4 set screws and mount it in your steady rest. Got your cat head that runs in your steady. Many ways to do it, just a little thought...

Remember you can't indicate the bore in the steady until you machine the OD to be concentric to the bore.

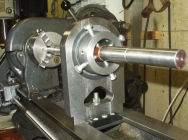

Yeah...thats definitely true just running in a steady. My other principle that ive used is like the attached pic. You can dial in then. I've done it several times on a small 12x36. I got plenty of rigidity to do anything gun wise on it...its good.Remember you can't indicate the bore in the steady until you machine the OD to be concentric to the bore.

Yeah...thats definitely true just running in a steady. My other principle that ive used is like the attached pic. You can dial in then. I've done it several times on a small 12x36. I got plenty of rigidity to do anything gun wise on it...its good. View attachment 1238558

So, after buying all this stuff it turns out the headstock on my lathe is way too long for a back side spider to do barrels. So, I would have to do between centers or I am thinking about buying the Viper fixture and using it in the 3 jaw chuck. IS there any reason this would not be a good purchase? I am officially out of money.

I put O-rings on the OD of the bushings I use.How true does your spindle bore run? I have a lathe that the headstock is too wide for barrel work but the thru hole is 2" and runs really true. I make rings that I press on the barrel and then turn the OD to just slip into the spindle bore. Then I have just been grabbing the barrel in the 4 jaw and reaching in with a long stem indicator to indicate the throat or muzzle depending on which end I'm working on. Not sure if this is the most accurate way but my chambers have been coming out great and the results on paper have been too.

Dave are you just dialing in the throat and muzzle still for barrel indication?I put O-rings on the OD of the bushings I use.