Jager

Gold $$ Contributor

“Case neck thickness congruency is unparralled (sp) when compared to any other neck turning system!”

The cost was utterly breathtaking. Two and a half grand is an awful lot of money for most of us.

But the promise it offered was tantalizing. Take the one handloading process which many of us find tedious and boring and lamentable and turn it into something almost akin to fun. And end up with a level of consistency and repeatability that bettered anything we had ever done before.

Was there, maybe, a competitive advantage hidden in that very steep entry fee?

I’m talking, of course, about F-Class Products’ innovative IDOD/AutoDOD neck-turning machine.

https://fclassproducts.com/autodod

Precision riflecraft is both a disease and a rabbit hole. It pulls you in, wallet first. I eventually caved, firing off an order to the good folks at @Bryan Blake 's shop. Two months later the large, heavy box showed up.

First impressions were beyond positive. We’ve all received countless packages, of course. This one was, for me, the first time that the packaging itself was an engineering marvel in and of itself. Long before you got to what was inside.

I shoot lots of different rifles. Lots of different calibers. But I’m primarily a short-range benchrest score shooter. And so although I envisioned using Bryan’s new invention in several different applications, my first and foremost use for it was to turn .30 BR brass.

No one makes .30 BR brass, of course. You have to form it yourself. I make mine out of virgin 6 BR brass. Usually Lapua. Sometimes Peterson.

Did I mention that I hate neck-turning?

I’ve been using a PMA tool (both Model A and Model B) and a hand drill. Works great. But fast that manual process is not.

One of the things I discovered some time ago with my manual neck-turn process is that although that process is both easy and straightforward, when I later took a ball micrometer and carefully measured neck wall thickness I could see a very slight difference between turning sessions. Cases turned today, despite using the exact same tools and the exact same process, would inevitably average out very slightly different to those turned a month ago. The difference was tiny, and almost certainly would never show up in results downrange. But I was taking no chances. I limited myself to turning relatively small batches – usually 50, no more than 100 cases – at a time, then kept each batch segregated.

It wasn’t lost on me that the IDOD – if I included the CNC-like AutoDOD option - would change all that.

There’s not an awful lot of information out there on the IDOD. But the handful of YouTube videos that are out there are fairly illuminating. And the color, printed-on-paper owner’s manual that ships with the machine is quite well done.

Once you cut through the newness of the machine, its initial sense of complexity disappears. Its concept of operation is pretty straightforward: A movable, in-and-out cutting head on one end; and a fixed collet on the other end to hold the piece of brass being turned.

The platform holding the cutting head can be moved back-and-forth perpendicularly to its normal in-and-out direction, in very tiny increments monitored with an attached dial gauge, and that’s how you adjust how much brass is being removed from the inside of the case neck. And the cutting head is itself adjusted, again in very tiny increments, to control how much brass is being removed from the outside of the case neck.

The AutoDOD option is like a mini-CNC, totally automating the speed and duration in which a cut is made. And since it’s the tiny variations in speed and duration that we introduce when turning necks by hand, the AutoDOD promises to have each case come out exactly, precisely the same.

The whole design is quite ingenious.

Getting things dialed in – the precise amount you want cut off the inside and the precise amount you want cut on the outside - is a little bit fiddly. And you’ll probably need to sacrifice a few pieces of brass. But that’s mostly a one-time thing. Unless you change caliber or headstamp or decide to change your neck thickness dimension, subsequent neck turning sessions should be pretty effortless.

Alas.

I won’t belabor the hours I spent trying one setup after another. Or the dozens and dozens of virgin Lapua – and, later, Peterson - 6 BR brass (formed into .30 BR) that were destroyed. What I ended up with, every single time, was gross variance in neck thickness.

In sample after sample, I would take a piece of .30 BR brass, formed out of virgin 6 BR, with negligible runout and with minimal case neck thickness variation, and after sending it through the IDOD/AutoDOD that neck thickness variation – the difference between the thickest and thinnest portions of the neck – would blow up. It wasn’t remotely concentric.

I kept persisting in my efforts, destroying more and more brass, because I felt surely it must be me doing something wrong. I re-did my setup from scratch easily half a dozen times.

Finally, after a long interval, I reached out to the good folks at F-Class Products. I received a prompt and pleasant reply with the suggestion that I purchase their new .330 Neck Full-Length Sizing Die (https://fclassproducts.com/purchase/p_3218469/30br-330nk-full-length-resizing-die), along with a .317 mandrel. Bryan recently came out with a video (

I had mixed feeling upon hearing this. On the one hand, the need for this new die and this new process suggested that I wasn’t alone in struggling to make the IDOD/AutoDOD work. On the other hand, that new die was itself $215, plus the cost of an oversize mandrel. More concerning than even that, though, was the premise for why this new .330 neck FL-Sizing die was necessary in the first place: brass was being heavily distorted when formed from 6 BR to .30 BR and thus needed to be “fixed.” My measurements told me otherwise.

In the end, though, it was a no-brainer. Having already invested nearly $3,000 in the IDOD/AutoDOD, a machine which had yet to turn a single usable case, I figured if another few hundred dollars was enough to get it working I’d be happy to pay it.

Having ordered the magic die, and with my query to F-Class Products on where I might obtain the odd-size .317 mandrel having gone unanswered, I looked around and found a 32-caliber .322 carbide expander mandrel from Brownell’s (https://www.brownells.com/reloading...ning/carbide-expander-mandrels/?sku=749014471) which I figured would work. With shipping that was another sixty-one bucks.

Throughout this whole, long saga with the IDOD/AutoDOD I had taken countless micrometer measurements, trying to figure out what was going on. With the new die and the new expander mandrel on the way, I decided to run as controlled a test as I possibly could.

From my diminishing supply of virgin 6 BR brass, I formed a couple dozen .30 BR cases. Half Lapua, half Peterson. From these newly-formed cases, I selected six random samples of Lapua and six random samples of Peterson.

I labeled each of these twelve pieces of brass with a unique identifier, using a sharpie. Three of the Lapua samples would be turned on the IDOD/AutoDOD; and three would be turned with my manual neck-turning process, using a PMA Model B and a hand drill.

Likewise for the six samples of Peterson.

My intent was to carefully measure each piece of brass through its entire lifecycle, from virgin 6 BR, straight out of the box, to fully formed and neck-turned .30 BR.

The rest of the brass I had formed would be used on the IDOD/AutoDOD, in advance of the six cases being tracked, in order to make sure its setup was as optimized as I could make it.

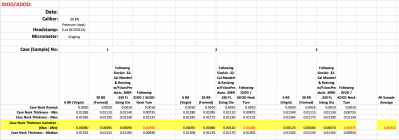

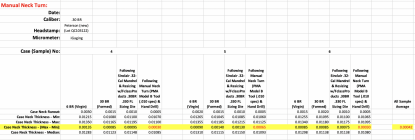

Here are the results of all those tests, first with the IDOD/AutoDOD-turned samples, followed by the manually neck-turned samples:

My first observation is that Bryan’s contention that forming .30 BR brass creates a heavily distorted case appears questionable. With negligible case runout and minimal neck thickness variation, it certainly seems to me that these formed cases are well controlled. For the record, the process I use for forming .30 BR cases is essentially the same as Wes demonstrates here (

My second observation is that the extra step of over expanding the case neck using, in my case, the .322 expander mandrel, and then squeezing it back down to size using Blake’s new .330 Neck FL-Sizing die, didn’t really do much. It didn’t materially make things better. Nor did it make them meaningfully worse. Cases were in good shape before they went through that process. And they remained in good shape afterwards.

It's when those cases go through the IDOD/AutoDOD that things go off the rails, with concentricity literally coming apart at the seams. Case neck thickness variation explodes. None of those cases are remotely usable.

In contrast, the cases turned manually, using a PMA Model B and a hand drill, are fine.

A word about measurements. Getting accurate measurements with a micrometer can be a thing, of course, especially as the level of precision increases. To keep this test as grounded as possible, I used a micrometer stand for all measurements, carefully positioning the depth of measurement – how deep into the neck – exactly the same for each reading. After the first reading on each sample, I rotated the case just a tiny amount, took another reading, rotated another tiny amount… and so on, until I had rotated through and measured the entire circumference of the case neck. Typically ten to twelve measurements for each. And noting both the smallest dimension and the largest dimension.

To say that this was tedious and time consuming is an understatement. But since concentricity – dead precise case neck thickness – lies at the very heart of what the IDOD/AutoDOD promises to provide, and since that’s the very thing I wasn’t getting, I felt it important to spend that time and make that effort.

Curiously, in the handful of YouTube videos out there that showcase the IDOD/AutoDOD, Bryan’s included, I’ve not seen anyone do that. What you see instead is guys hurriedly taking a spot reading or two and, I guess, assuming that what they measured must hold for the entire circumference of the neck.

When I sent these results to F-Class Products, with a polite query if there was anything else I could try, I was met with silence.

I’d be happy to be told I’m an idiot. That I obviously don’t know how to form .30 BR brass. Or clearly I’m a klutz with a micrometer. Something. Anything. But nope. Just silence.

I think the kids call it ghosted, these days.

Our shooting world is blessed with many one-man shops and small, family-owned businesses. The products and services we receive from those many small outfits brings much richness to our sport. I wish Bryan and his team nothing but the best. I genuinely mean that.

But I’m left with the inevitable conclusion that the IDOD/AutoDOD simply doesn’t work on .30 BR brass. Maybe it does with other calibers. Probably it does. Hopefully it does. But after destroying well over a hundred virgin 6 BR cases in the attempt, I think I’m done.

And much as posting this pains me, it pains me even more to think of the next guy down the line making the same mistake I did.

Three grand is a lot of money.