Boveda packs contain a solution of glycerol and water contained in a membrane packet that allows water vapor to move through it. You are placing a foreign material into the powder container which has acetone in it which may or may not react with the membrane.

If a container of powder is stored at some ideal % humidity, you open the container pour it into a powder measure then pour it into a scale pan, how long does it take for the powder to pick up water. If I had an electronic scale I would put some powder on the scale pan and check the weight every few hours for a weight increase. The results would be interesting. Cannot believe something this easy hasn't been posted. The results would vary depending on the difference between the container humidity and the room humidity. In the Byran Litz video he gave an example of a 200 fps increase due to a lower humidity charge apparently burning faster.

Does it help to control the container humidity if the powder starts absorbing water as soon as you open the container or is it a very slow process?

Vitavouri article on water content.

Variations in moisture content change the burning rate of a powder and thereby chamber pressures and muzzle velocity. The moisture content of the N100 and N300 series powders is usually around 1 %, the N500-series’ normal moisture content is 0.6 % because of the added nitroglycerine. So what...

www.vihtavuori.com

Frrom Norma Powder

Most shooters realize that significant changes in temperature will alter how powders perform. That's why you want to keep your loaded ammo out of the hot sun, and keep rounds out of a hot chamber until you're ready to fire. But there are other factors to be considered -- HUMIDITY for one.

bulletin.accurateshooter.com

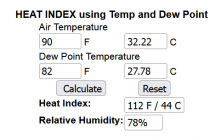

s is unfortunate that all of this humidity discussion is going on and people are running test that do not reflect how powder reacts with air. Fundamentally relative humidity is the wrong variable to even be discussing. The actual variable that affects the moisture exchange is partial pressure of the water in air. The normal temperature that corresponds to this is dew point temperature. While humidity changes throughout the day, dew point doesn't, except when air masses change. From a practical standpoint air at 70F and 50% relative humidity has the same dew point and partial pressure as air at 110F and 14% RH and the same effect on powder. For those familiar with the Norma Chart (

https://chronoplotter.com/2021/08/19/how-does-humidity-affect-powder/), the relative humidity displayed is at a constant temperature and represents dew point temperatures of about 38F to 68F. Equilibrium between air and nitrocellulose is only a function of dew point/partial pressure.

Nitrocellulose behaves much the same as wood (cellulose) and if you are familiar with extremes of humidity (summer vs winter) and the behavior of wood trim or flooring you know that the wood will swell in the summer and shrinkk in the winter as the relative humidity and dew point in the house change. The change however take time. That time is not measured in minutes or hours but in days and weeks. While wood is solid smokeless powder is made up of small particles/grains of powder. However it commonly exists in what is called a packed column. When in a cartridge case or stored in a jug most of the powder is in contact with air which it is in equilibrium with and that air is trapped between the grains. Only a small portion of the surface is exposed to the air above the powder. Because hygroscopic behavior is a surface effect the grains do not magically loose all their moisture at once. It takes time for the moisture to migrate to the surface.

Air at any temperature will only hold a small amount of moisture. To demonstrate, an 8lb jug of powder has a volume of about 1.2 gallons or .16 cubic feet. If it contains one pound of powder which occupies about 0.018 cubic feet leaving the moist air to occupy about 0.142 cubic feet. If the powder shipped with 1% moisture then it will contain .01 lbs of water. It is common to load powder in an environment of about 70F and 50% or greater to prevent the possible buildup of static electricity. We can assume the powder is in equilibrium with air at 70F and 50% RH (dew point of 50.5F) and the air has a H2O content of 0.000082Lbm. If we were to open the jug and replace the air with 105F and 25% RH (dew point of 62F) the maximum amount of H2O that could be gained is 0.000035 lbs, making the total amount of H2O in the powder .010035 lbs for an increase of 0.35%. The actual gain would be less than this as the vapor pressure of the powder increases and the vapor pressure of the of the air decreases.

After the jug of powder is opened the only source of moisture/air exchange is the the seal on the top. When sealed the major source of air exchange with the environment is via pressure differences between the air inside the jug and ambient. The two sources of these pressure differences are ambient temperature which tends to not be a factor for small, slow changes in temperature because the temperature of the air in the jug will follow close behind the ambient and changes in barometric pressure which will cause very small changes in the total mass of air in the jug.

Powder moved from a jug to a dispenser and back does not typically have enough time to exchange anything but a very minor amount of moisture with air and the minor amount of air trapped within the packed bed will quickly reach equilibrium.

If humidity changes were as significant as some people tend to imply, powder manufactures would go beyond there normal recordsmmendations. The below is from Vihtavouri's Loading Manual:

STORE IN A COOL, DRY PLACE. Be sure the storage area selected is free from any possible sources of excess heat and is isolated from open flame, furnaces, hot water heaters, etc. Do not store smokeless powder where it will be exposed to the sun’s rays. Avoid storage in areas where mechanical orelectrical equipment is in operation. Restrict from the storage areas heat or sparks which may result from improper, defective or overloaded electrical circuits.

DO NOT STORE SMOKELESS POWDER IN THE SAME AREA WITH SOLVENTS, FLAMMABLE GASES OR HIGHLY COMBUSTIBLE MATERIALS. STORE ONLY IN DEPARTMENT OF TRANSPORTATION APPROVED CONTAINERS.

Do not transfer the powder from an approved container into one which is not approved.

It should be obvious that the powder should be kept dry. As for cool, this is to reduce the rate that the powder decompose and releases nitric acid. The life of powder is dependent on the stabilizers used to limit the nitric acid buildup. When depleted the powder goes bad.

For loaded cartridges the same principles apply but a normal round will contain almost no free air. Most is within the packed bed of powder. Again the mechanisms for exchange with ambient air are the same. While the bullet and primer are not hermetically sealed little air as a percent of total air will move into or out of the cartridge. As for military rounds the sealant is not for humidity effects but to protect the integrity of the cartridge if/when it becomes submersed in water.

A note on test that are run with various humidity packets. These involve the forced humification or drying of powder by an external hygroscopic solution. In many cases it reflects conditions that do not reflect the actual conditions that reasonably stored powders could ever achieve.