Why a blade mic? The case body is generally round x tapered so no matter what geometry your mic is, it contacts at two points.

David

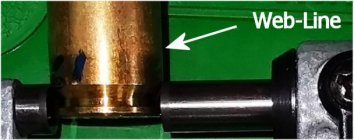

With a blade mic, you can measure the extractor groove and get a measurement that no other mic can reach, but I don't recommend it. The brass is much thinner there than the web, and will show more expansion for the same charge. Instead, I just move up to the web area and measure there. Sometimes that web area can be really narrow on small cases, and a blade mic set right next to the groove will easily measure it. The rim can be larger than the web on some cases, so a regular mic won't work there.

Measuring expansion doesn't tell you how much pressure you have. It just tells you when the brass you are using has been pushed past it's limit. Make a ladder in .1gr increments and measure the results. That's how you determine what the limits are for your brass in your rifle.

As an example, I recently tested LT-32 in my 6PPC. A powder I had never used in anything, with a new to me cartridge. I started at 28.0grs and loaded all the way up to 29.5grs. I figured I would get a heavy bolt lift or a click at the top of the bolt lift to signal when loads were getting too high. Neither of those happened. The first clue I had that I was over pressure was when the last case left the primer in the bolt raceway.

Starting at 28.3 and all the way up to 28.9, the expansion was only .0002, from 29.0 to 29.3, it only gained .0002 more, then 29.4 added another .0002. So from 28.3 to 29.3, the cases had only expanded .0006. Next up was 29.5, and that .1gr alone expanded the case .0007, knocking the primer clean out. I settled on 29.1grs as 29.3 can loosen the pockets even though it still shoots great. No reason to beat up the brass for that tiny gain in FPS.

Now, I have an expansion measurement that I can use for any other powder in this gun. So far N133 hasn't gotten close, and I haven't tried H322 yet, probably won't either. Some brass won't take much pressure either. I used Keith Glasscock's method of fireforming on these cases and couldn't be happier with it. My pockets are all still tight, and even after 6 firings the pocket uniformer doesn't do anything other than remove carbon. Blade mics aren't cheap, but they are the only way to know how much your brass will take. They're a damn sight cheaper than an induction annealer, labradar, or primer seater at 600 bucks.