I don't have anyone to teach me this stuff, except y'all Iv been to a few matches. Put together a dozen or more Br rigs. I read on here. It's certainly an addiction. I guess it's a good one though.

Sorting bullets!

I'm sorting Berger 108s. In this picture, Is this the correct way to measure base to ojive?

If it is ,will work this way? , Is this more important than say a .1 of a grain difference in bullet weight?

I started measuring some and right away I started seeing a variance.

I seat my bullets in a away I try and get the ojive of the bullet say .010 from lands. But Iv noticed when I set my die I still get a variation. I'm hoping this will go away if I sort.

I would not want to try and compare the value of sorting bullets BTO versus sorting bullets into 0.1 gr increments. For what it's worth, I don't do either of those things, and I susoect it's not an "apples-to-apples" comparison, anyhow. Regardless, others are welcome to test and attempt to define the relative value of those sorting approaches if they wish.

What I

can tell you is that length-sorting Berger bullets can most certainly be of benefit, but I'm talking about sorting by overall length, not base-to-ogive. In my hands, the BTO measurements of the various Berger bullets I use are actually pretty consistent. In contrast, there is a fair bit of overall length variance in every Lot #/batch I've ever sorted. Typically, I observe an OAL variance of up to .015" to .020" in a Lot # of Berger bullets, usually with a very small number

extreme outliers that would push the average length variance even higher if included.

What it means when the BTO measurements are fairly consistent, but the OAL measurements have significant variance is that the

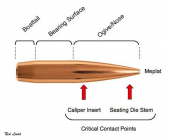

majority of length variance lies in the nose region of these bullets. This is important for your question because the two critical contact points for seating depth, i.e. the point where the seating die stem contacts and "pushes" the bullet down into the case, and the point on the bullet ogive just above the bearing surface where our caliper insert contacts the bullet when we measure caertirdge base-to-ogive (CBTO). Any length bullet-to-bullet length variance between these two critical contact point can therefore lead to seating depth inconsistency.

As illustrated in the cartoon below, both of these critical contact points lie

outside the BTO dimension. In other words, sorting bullets by BTO is

not going to improve seating depth variance caused by length variance in the nose region of the bullet. For that reason and for the purpose of pointing bullets, I sort them by OAL, not BTO, and the benefits of sorting by OAL and pointing can readily be documented on a target at distances of as little as 300 yd. The elevation required to center a group at 300 yd typically decreases by about 1/8th to 1/4 MOA for pointed bullets as compared to unsorted/unpointed. This is not surprising as it is well documented that pointing bullets increases BC by a small amount, so they require a bit less elevation at a given distance. However, in my hands the groups also routinely became tighter, which I suspect may be a function of the length-sorting process, at least in part. If you're wanting to see whether length-sorting can help with seating depth consistency, try sorting by OAL and see how it works for you.