we need an emoji that looks like a steaming pileFor the most part within .0005” with digital calipers. I can do that without anealing. IMO lube and lube technique is a big part of it and I’d say probably the most important. As mentioned a little dwell at top of stroke can help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How consistent are your full length resizing numbers?

- Thread starter Toemader

- Start date

WSnyder

Silver $$ Contributor

And the reason I mentioned digital calipers? We all know that the number shown isn’t the exact number right??? That there’s quite a bit of tolerance one way or the other in the readout, no???we need an emoji that looks like a steaming pile

I cant even see half a thousandth of an inch. So I am sure my rifle wont notice it either after the first shot puts carbon in its chamber. Reloaders should put a piece of tape over the 4th digit on calipers so they cant see it when measuring HS with a stoney point type comparator.

Ned Ludd

Silver $$ Contributor

The limitations of most reloading calipers are obvious. A quality set of calipers typically has readability to .0005", and accuracy to +/- .001". It is common to report measurement values exactly as read from the instrument. There is nothing wrong with doing this. If someone wishes to include the "+/-" value with every measurement they report, have at it. I will report values as taken directly from the instrument with the implicit understanding that these values include an error/uncertainty component. Everyone that reads measurement values posted anywhere online needs to be aware of the limitations of such measurements, but it's not my job to list the specific limitations of the equipment I use to take the measurements every time I post a piece of informations. If someone is unaware that all measurements contain some degree of uncertainty, that is on them.

WSnyder

Silver $$ Contributor

Why? It still gives you a reference as to where you are as long as you are conscious of the tolerance and capability of the tool. On my analogs I’ll take note of and will split the lines.Reloaders should put a piece of tape over the 4th digit on calipers so they cant see it when measuring HS with a stoney point type comparator.

WSnyder

Silver $$ Contributor

I will report values as taken directly from the instrument with the implicit understanding that these values include an error/uncertainty component. Everyone that reads measurement values posted anywhere online needs to be aware of the limitations of such measurements,

If someone is unaware that all measurements contain some degree of uncertainty, that is on them.

Exactly, well said!

6BRA

Gold $$ Contributor

Measuring to a ten thousandth of an inch requires a special feel and a special tool. Not likely done with calipers. My experience measuring to a 10 thousandth is done on an average of several measurements. Pressure is the variable. But can be done repeatable with the right tool.$$$Most Short Range Benchrest Shooters get pretty aggressive with the shoulder bump and body sizing. You want the cases going in easy and coming out easy.

Granted, they will come on here and throw around ridiculously small tolerances in “tenths”, when in reality most are in the .002to .003 range on the shoulder bump. Many do not want to say what they really do, and what really works, because of the perceptions that are out there.

As has been noted, if you are wanting to measure in very small numbers, you need the tools to do it. And, you need to be proficient in using them.

The one thing you never want to rely on is “Feel”. I have Seen shooters keep sizing down untill the bolt drops easy, thinking they finall y have about .001 bump, when in actuality had as much as .010.

There more are things that influence this than simply pushing the shoulder back.

Many of us who have the means and time to do it have experimented with just about every sizing combination imaginable. The truth is, it simply doesn’t matter that much until you get into a potentially hazardous situation of entirely too much headspace that can lead to a head separation after numerous firings.

A while back, a fellow Benchrest Shooter and friend of mine, were discussing some of the topics on the Internet, and he made an interesting statement. It kinda went like…..”Benchrest shooters, who shoot groups measured in thousandths of an inch, work in numbers to the nearest “thousanth” of an inch. Shooters who shoot at 12” diameter pie plates and consider a hit good enough work in “one ten thousanth” of an inch”

He was being facetious, but there might be some truth to that.

Spot on!Most Short Range Benchrest Shooters get pretty aggressive with the shoulder bump and body sizing. You want the cases going in easy and coming out easy.

Granted, they will come on here and throw around ridiculously small tolerances in “tenths”, when in reality most are in the .002to .003 range on the shoulder bump. Many do not want to say what they really do, and what really works, because of the perceptions that are out there.

As has been noted, if you are wanting to measure in very small numbers, you need the tools to do it. And, you need to be proficient in using them.

The one thing you never want to rely on is “Feel”. I have Seen shooters keep sizing down untill the bolt drops easy, thinking they finall y have about .001 bump, when in actuality had as much as .010.

There more are things that influence this than simply pushing the shoulder back.

Many of us who have the means and time to do it have experimented with just about every sizing combination imaginable. The truth is, it simply doesn’t matter that much until you get into a potentially hazardous situation of entirely too much headspace that can lead to a head separation after numerous firings.

A while back, a fellow Benchrest Shooter and friend of mine, were discussing some of the topics on the Internet, and he made an interesting statement. It kinda went like…..”Benchrest shooters, who shoot groups measured in thousandths of an inch, work in numbers to the nearest “thousanth” of an inch. Shooters who shoot at 12” diameter pie plates and consider a hit good enough work in “one ten thousanth” of an inch”

He was being facetious, but there might be some truth to that.

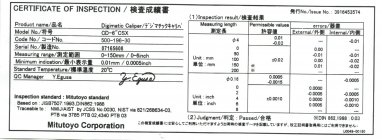

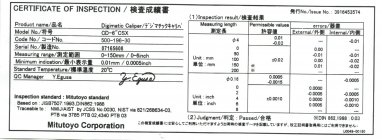

No, I'm afraid that there are still lots of people that believe that because they bought a nice set of Mitutoyo calipers that they should be able to measure in tenths. It's just the wrong tool for that job, regardless of brand or price.And the reason I mentioned digital calipers? We all know that the number shown isn’t the exact number right??? That there’s quite a bit of tolerance one way or the other in the readout, no???

WSnyder

Silver $$ Contributor

Well we’re educating them right here in this threadNo, I'm afraid that there are still lots of people that believe that because they bought a nice set of Mitutoyo calipers that they should be able to measure in tenths. It's just the wrong tool for that job, regardless of brand or price.

Everything I measure with calipers is within 5/10,000Well we’re educating them right here in this thread

Not to mention stacking tolerance!Measuring to a ten thousandth of an inch requires a special feel and a special tool. Not likely done with calipers. My experience measuring to a 10 thousandth is done on an average of several measurements. Pressure is the variable. But can be done repeatable with the right tool.$$$

Paul

Exactly Jackie, kind of like not seeing the forest for all the trees.Most Short Range Benchrest Shooters get pretty aggressive with the shoulder bump and body sizing. You want the cases going in easy and coming out easy.

Granted, they will come on here and throw around ridiculously small tolerances in “tenths”, when in reality most are in the .002to .003 range on the shoulder bump. Many do not want to say what they really do, and what really works, because of the perceptions that are out there.

As has been noted, if you are wanting to measure in very small numbers, you need the tools to do it. And, you need to be proficient in using them.

The one thing you never want to rely on is “Feel”. I have Seen shooters keep sizing down untill the bolt drops easy, thinking they finall y have about .001 bump, when in actuality had as much as .010.

There more are things that influence this than simply pushing the shoulder back.

Many of us who have the means and time to do it have experimented with just about every sizing combination imaginable. The truth is, it simply doesn’t matter that much until you get into a potentially hazardous situation of entirely too much headspace that can lead to a head separation after numerous firings.

A while back, a fellow Benchrest Shooter and friend of mine, were discussing some of the topics on the Internet, and he made an interesting statement. It kinda went like…..”Benchrest shooters, who shoot groups measured in thousandths of an inch, work in numbers to the nearest “thousanth” of an inch. Shooters who shoot at 12” diameter pie plates and consider a hit good enough work in “one ten thousanth” of an inch”

He was being facetious, but there might be some truth to that.

OP, just read through the first page and go with those suggestions. This will likely turn into a caliper accuracy topic from here. I’d just bump back 2-3K and call it good. This should keep you from being snug on some cases that don’t size enough. You probably won’t shoot the difference.I am having some issues with consistency when I resize my 6.5x47 brass. I assume that if I am trying to size my brass to 1.4655 then it should probably never get outside of 1.4665 to 1.4645. Does this sound reasonable? I actually feel like it should stay within .0005, but I am new to this endeavor.

Yes, I typically will lose primer pockets with the loads I normally shoot first. Well before I have to worry about a thou or so extra shoulder bump becoming a problem to brass life. Like Jackie, said, the rifle needs to run smoothly and as I said before, I don't want a few snug cases in the batch, while the others are not. Without debating the actual cause in depth, at the least, a snug case may well set up a different vibration pattern as opposed to one with a couple of thou clearance as well as that clearance may allow the case to drive forward when the fp hits the case and now I'm a couple of thou closer to the lands..fwiw. I just want the gun to run smoothly and all to be the same within about a thou regarding shoulder bump. I typically bump my shoulders about .0025-.003...Again, more than many on here claim to be using but it works well for me. Whatever one does, if it works..hey, keep doing that. Lol!Exactly Jackie, kind of like not seeing the forest for all the trees.

Same here and same reason, it seems.OP, just read through the first page and go with those suggestions. This will likely turn into a caliper accuracy topic from here. I’d just bump back 2-3K and call it good. This should keep you from being snug on some cases that don’t size enough. You probably won’t shoot the difference.

D Coots

Silver $$ Contributor

I just want the gun to run smoothly and all to be the same within about a thou regarding shoulder bump. I typically bump my shoulders about .0025-.003...Again, more than many on here claim to be using but it works well for me. Whatever one does, if it works..hey, keep doing that. Lol!

Gun running smoothly is paramount. I seldom measure bump. Same reamer and same die that is adjustable to a half a thou. My gunsmith chambers are very close to perfect. I know where my die needs to be. Don't reccomend for new guys.

At the end of every agg I check the fit of the brass in the chamber...no primer, no fp. No measuring....Don't care what they measure, only care about feel. Usually Some need bumped a tad. I like to feel resistance a bit before bolt closes.

With my die if I oversize I'll get clickers. Oversize to me is no resistance on bolt closure.

Interesting...clickers from over sizing?Gun running smoothly is paramount. I seldom measure bump. Same reamer and same die that is adjustable to a half a thou. My gunsmith chambers are very close to perfect. I know where my die needs to be. Don't reccomend for new guys.

At the end of every agg I check the fit of the brass in the chamber...no primer, no fp. No measuring....Don't care what they measure, only care about feel. Usually Some need bumped a tad. I like to feel resistance a bit before bolt closes.

With my die if I oversize I'll get clickers. Oversize to me is no resistance on bolt closure.

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.