When I prepare cases (30BR), fire form then repeatedly reload them (Lapua cases), I number them just below the case shoulder on the main body of the case using a fine point black sharpie pen. I number them to help me keep track of which case is which when testing/comparing various variables for POI precision (group size). The thickness of the black ink is about .0003" based on my mic measurements. I don't think this small added thickness at this location on the case affects POI precision, but I don't know. I could test for this variable but thought I would ask you all this question first. Is there a way to number cases without adding or subtracting thickness to any part of the case?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How can I number cases without changing case thickness?

- Thread starter Cassidy

- Start date

TheCZKid

Silver $$ Contributor

When I load test I use a thin sharpie to write what is loaded on the sides of the cases, I can't imagine that super small thickness would make any notable or measurable difference. The many other variables in shooting would have a much more significant impact, as any testing for .0003 ink thickness would be impossible to isolate. Just my thinking.

Like @TheCZKid said, I highly doubt the tiny bit of sharpie will make any difference at all.

I use a color coding system. I have like 15 different color sharpies that mean different things. When I do load development, the load gets labeled with all the info I'll need and the primer pocket gets a colored ring with a sharpie. This allows me to quickly identify the powder charge as well as the spent brass later when I measure them and look for pressure signs to see how the charge affected the brass.

My targets get marked with the identification number that's on the top right of the label to correlate which target goes with which load. The label then gets filed away to reference later if needed.

I use a color coding system. I have like 15 different color sharpies that mean different things. When I do load development, the load gets labeled with all the info I'll need and the primer pocket gets a colored ring with a sharpie. This allows me to quickly identify the powder charge as well as the spent brass later when I measure them and look for pressure signs to see how the charge affected the brass.

My targets get marked with the identification number that's on the top right of the label to correlate which target goes with which load. The label then gets filed away to reference later if needed.

memilanuk

Gold $$ Contributor

When I prepare cases (30BR), fire form then repeatedly reload them (Lapua cases), I number them just below the case shoulder on the main body of the case using a fine point black sharpie pen. I number them to help me keep track of which case is which when testing/comparing various variables for POI precision (group size). The thickness of the black ink is about .0003" based on my mic measurements. I don't think this small added thickness at this location on the case affects POI precision, but I don't know. I could test for this variable but thought I would ask you all this question first. Is there a way to number cases without adding or subtracting thickness to any part of the case?

Looks like someone has got cabin fever *bad* this year...

I propose that you run a test where you position the writing at four different points, ninety degrees apart, and see if there is any detectable change in POI between the four positions. Be sure to use statistically valid sample sizes - at least 30 shots at each position, fired in random order to preclude any bias from conditions, with ammo loaded into the gun by someone else so the shooter cannot unconsciously bias the shots. Also, make certain you use mean radius (not extreme spread) and standard deviation - and be sure to use stdev.s, not stdev.p when you calculate that.

I'll be really interested to see how you intend to make sure the cases are loaded *exactly* 90 degrees out from each other, not 88 degrees or 90.2 degrees.

Or we can stop being silly worrying about 0.0003" of ink on the case shoulder. If you F/L size at *all*, I'd wager the sizing die squeezes the shoulder something more like 0.002-0.003" - literally an order of magnitude more. Then with the bullet seated into the lands, or even with it just in the freebore - which probably has a clearance of 0.00025" or less (0.308" bullet in a 0.3085" freebore)... it really, really does not matter.

But hey, you do you

Doug Beach

Silver $$ Contributor

Now try to mark them without changing their weight…

Laser engrave them. 0.0005 deep would change the weight by an insignificant amount.

memilanuk

Gold $$ Contributor

The laser will make a weak place on the case body. You would have to do it on the head.

Frank

Frank

JEFFPPC

Gold $$ Contributor

If you put this effort into reading condtions and bench manners you would become a consistent competitor way quicker than the road your traveling.When I prepare cases (30BR), fire form then repeatedly reload them (Lapua cases), I number them just below the case shoulder on the main body of the case using a fine point black sharpie pen. I number them to help me keep track of which case is which when testing/comparing various variables for POI precision (group size). The thickness of the black ink is about .0003" based on my mic measurements. I don't think this small added thickness at this location on the case affects POI precision, but I don't know. I could test for this variable but thought I would ask you all this question first. Is there a way to number cases without adding or subtracting thickness to any part of the case?

Krogen

Gold $$ Contributor

Well, y’all have got me thinking. No small feat sometimes! I mark case heads with a black sharpie. Not that I sweat the thickness or weight, but it’s a bit annoying to have to clean off the marks for the next go-round. Somebody above mentioned different color sharpies. I think I’ll go that route and just mark the primer. Mark goes away with depriming. And back to the thickness issue: I’m sure my primers are at least a few tenths below the case head, so no worries!

Sounds like compulsive behavior. Put your Mickey Mouse ears on while measuring for max accuracy.If you put this effort into reading condtions and bench manners you would become a consistent competitor way quicker than the road your traveling.

Last edited:

According to some testing done by the website 'hackaday', black sharpie is much, much thinner than the .0003 you think you are measuring. Below is link to their article which includes a YT video of their test.

Here is a summary of their findings from the article:

The results? Black, blue, and red Sharpie were all tested, alongside blue and black Dykem layout fluid. Ten samples of each were run and the readings were all very close, save a couple of obvious outliers. Clocking in the thinnest is black Sharpie at about 118 millionths of an inch (~30 microns) and blue Dykem was the thickest at 314 millionths (86 microns).

hackaday.com

hackaday.com

Here is a summary of their findings from the article:

The results? Black, blue, and red Sharpie were all tested, alongside blue and black Dykem layout fluid. Ten samples of each were run and the readings were all very close, save a couple of obvious outliers. Clocking in the thinnest is black Sharpie at about 118 millionths of an inch (~30 microns) and blue Dykem was the thickest at 314 millionths (86 microns).

Measuring Sharpie Thickness… The Ink Itself, Not The Pen!

How we missed this one from a few years ago is unknown, but we’re glad to catch up with it now. Have you ever needed to measure how thick the ink in a Sharpie line is? Of course you havenR…

You know, I have serious OCD and it never occurred to me to worry about my Sharpie marks on the case. God, now another thing to sweat over, on my loads.

I really don’t believe that I’m a good enough shot, that whatever the thickness of the Sharpie mark is, will have an affect my groups on paper. Just sayin.

I really don’t believe that I’m a good enough shot, that whatever the thickness of the Sharpie mark is, will have an affect my groups on paper. Just sayin.

Here's the test and results:

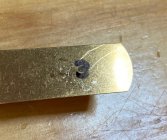

I used a feeler gauge (0.010") which appears to be brass and checked its thickness using a Starret No. 3732XFL-1 mic (see pic; it's zero'd). The mic's info pamphlet says it's resolution is .00005" and it's accuracy is plus or minus .0001".

After acetone cleaning the feeler gauge with microfiber cloth, drying it and again checking for zero on the mic, ten readings of the gauge thickness were .00985" for six of the readings and .00990" for four of the readings, n=10, for a mean of .00987, median .009085, and SD .0000258".

Then I used a Sharpie fine point black permanent marker (the ink comes off brass with acetone; same marker I use to number my cases) and wrote "3" (once) on one part of the feeler gauge (see pic) and re-checked that the mic was zero'd. After allowing the ink to dry, repeated readings (n=9) directly on the "3" using the mic were .00985" for five readings and .00990" for four readings; a mean of .00987", median of .00985" and SD of .0000264".

Essentially, using this mic, the thickness of the feeler gauge with and without a single "3" mark were the same. However, I because I was getting mic values that very slightly differed (.00900 vs .00985) when repeating the same measurement, I think I was at or near the limit of the mic's accuracy.

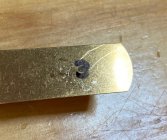

Therefore I performed the same test again but this time I wrote "3" at the same location on the feeler gauge five times each superimposed on each other and allowing the "3" to completely dry each time to my eye (about 1 min); see pic where the "3" appears darker than when applied once. It's possible that some of the ink came off (dissolved onto the pen) as I superimposed each of the "3's" but looking at it each time, I don't think so.

Measurements of thickness of the gauge without the five "3s" was .00990" for all of ten readings, and .01010" with the five "3s" for all of five readings. The difference was .00020", and divided by 5 the result was .00004". These data suggest each application of the "3" was about .00004" thick which to me seems negligible for purposes of preparing rounds for precision shooting.

I used a feeler gauge (0.010") which appears to be brass and checked its thickness using a Starret No. 3732XFL-1 mic (see pic; it's zero'd). The mic's info pamphlet says it's resolution is .00005" and it's accuracy is plus or minus .0001".

After acetone cleaning the feeler gauge with microfiber cloth, drying it and again checking for zero on the mic, ten readings of the gauge thickness were .00985" for six of the readings and .00990" for four of the readings, n=10, for a mean of .00987, median .009085, and SD .0000258".

Then I used a Sharpie fine point black permanent marker (the ink comes off brass with acetone; same marker I use to number my cases) and wrote "3" (once) on one part of the feeler gauge (see pic) and re-checked that the mic was zero'd. After allowing the ink to dry, repeated readings (n=9) directly on the "3" using the mic were .00985" for five readings and .00990" for four readings; a mean of .00987", median of .00985" and SD of .0000264".

Essentially, using this mic, the thickness of the feeler gauge with and without a single "3" mark were the same. However, I because I was getting mic values that very slightly differed (.00900 vs .00985) when repeating the same measurement, I think I was at or near the limit of the mic's accuracy.

Therefore I performed the same test again but this time I wrote "3" at the same location on the feeler gauge five times each superimposed on each other and allowing the "3" to completely dry each time to my eye (about 1 min); see pic where the "3" appears darker than when applied once. It's possible that some of the ink came off (dissolved onto the pen) as I superimposed each of the "3's" but looking at it each time, I don't think so.

Measurements of thickness of the gauge without the five "3s" was .00990" for all of ten readings, and .01010" with the five "3s" for all of five readings. The difference was .00020", and divided by 5 the result was .00004". These data suggest each application of the "3" was about .00004" thick which to me seems negligible for purposes of preparing rounds for precision shooting.

Here's the test and results:

I used a feeler gauge (0.010") which appears to be brass and checked its thickness using a Starret No. 3732XFL-1 mic (see pic; it's zero'd). The mic's info pamphlet says it's resolution is .00005" and it's accuracy is plus or minus .0001".

After acetone cleaning the feeler gauge with microfiber cloth, drying it and again checking for zero on the mic, ten readings of the gauge thickness were .00985" for six of the readings and .00990" for four of the readings, n=10, for a mean of .00987, median .009085, and SD .0000258".

Then I used a Sharpie fine point black permanent marker (the ink comes off brass with acetone; same marker I use to number my cases) and wrote "3" (once) on one part of the feeler gauge (see pic) and re-checked that the mic was zero'd. After allowing the ink to dry, repeated readings (n=9) directly on the "3" using the mic were .00985" for five readings and .00990" for four readings; a mean of .00987", median of .00985" and SD of .0000264".

Essentially, using this mic, the thickness of the feeler gauge with and without a single "3" mark were the same. However, I because I was getting mic values that very slightly differed (.00900 vs .00985) when repeating the same measurement, I think I was at or near the limit of the mic's accuracy.

Therefore I performed the same test again but this time I wrote "3" at the same location on the feeler gauge five times each superimposed on each other and allowing the "3" to completely dry each time to my eye (about 1 min); see pic where the "3" appears darker than when applied once. It's possible that some of the ink came off (dissolved onto the pen) as I superimposed each of the "3's" but looking at it each time, I don't think so.

Measurements of thickness of the gauge without the five "3s" was .00990" for all of ten readings, and .01010" with the five "3s" for all of five readings. The difference was .00020", and divided by 5 the result was .00004". These data suggest each application of the "3" was about .00004" thick which to me seems negligible for purposes of preparing rounds for precision shooting.

View attachment 1516212View attachment 1516213View attachment 1516214

What size groups do you typicaly shoot with your rifle? There are so many variables involved in shooting small groups that you need a significant inprovement to see a difference. If you cannot consistantly shoot small round groups looking for small improvements is hopeless. I would think that if you had a great rifle and you were a world class shooter you would have to shoot in a tunnel to hope to see a small improvement. Your not going to go from a .220" aggregate to a .200" aggregate doing what your doing. Different lots of primers, bullets and powder? Probably the best thing you can do is improve wind reading skills and bench mannersWow, thanks, Fork! I'm going to mic it again, this time on a flat piece of metal; will post the results here with pics.

The last set of 4-shot groups where I was testing 3 different neck thickness' were .230, .200 and .224; ammo and rifle are not fully tuned. I've got several variables I'm testing/working on to try to get the group size smaller in the 0 to 1.5 range. Also working on wind conditions as always; the elephant in the room.

Similar threads

- Replies

- 16

- Views

- 2,768

- Replies

- 10

- Views

- 1,525

- Replies

- 18

- Views

- 1,027

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.