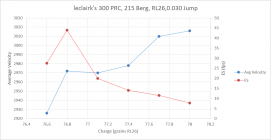

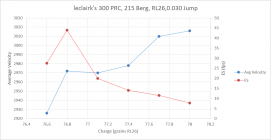

Loading 300PRC, 215gr Bergers, RL 26, ADG Brass, .03 off lands, 3 shot groups, none of the groups were particularly good (about 1 MOA)

76.5gr- av 2926 fps, ES 27.5

76.8gr- av 2972 fps, ES 44

77.1gr- av 2970 fps, ES 20

77.4gr- av 2978 fps, ES 14

77.7gr- av 3010 fps, ES 11.5

78 gr - av 3016 fps, ES 7.7

I had loads at 78.3 and 78.6 but I started getting nervous with those velocities at 78gr. I saw no pressure signs other than a very slight stiff bolt. Looks like a node at 77ish but the ES is not that great. I like ES at 77.7-78 and the velocities seem consistent. How do you think I should proceed? Also interesting to me that my ES continues to drop as my charge increases.

when you shoot 3 shot GROUPS you are not shooting a LADDER, just old fashion nothing wrong with it GROUPS. a ladder is single shots just like a real world ladder you climb..single steps as you go up

Hired Gun Painting

Silver $$ Contributor

when you shoot 3 shot GROUPS you are not shooting a LADDER, just old fashion nothing wrong with it GROUPS. a ladder is single shots just like a real world ladder you climb..single steps as you go up

Please explain to us how this isn't a ladder test.

3 shots each charge shot at same point of aim, bullets colored for clarity.

In case this helps to visualize your data.

Not to start a debate about what is or isn't a ladder, or an Audette Ladder.... but just because there are three samples instead of one doesn't mean it isn't a ladder, that just means it has three samples.

In my past, we called an Audette Charge Ladder a test that went to distance in order to watch the shotfall, and many times that meant without a chronograph. That was to identify vertical nodes, and it could be one string or even several samples per charge step.

Like any small sample testing, we must be careful not to read too much into the samples since we know that there is an unknown dispersion for each one that is TBD.

Nothing wrong with the test, but it didn't sound like there were any group center locations or vertical data taken, which is a shame since the most critical data can often be found there.

How do you think I should proceed?

Sorry to hear the group size wasn't to your liking, but it takes some elbow grease to determine if the gun likes the recipe. Sometimes, it doesn't...

If I were to run this test, I would shoot it at a good distance. For example, if you are thinking of competition at 1000, then shoot it at 1000. Or, if hunting, go out past where your max distance would be.

Guns like this, I would test at least 600 yards if not more.

Run the charges in finer steps, but aim at the same point and let the shotfall show you where there are vertical nodes. Then, I would take the most promising node and run a group test, followed with a seating depth test at that charge. (If you load at the range with pre prepped brass, then you can let the gun show you when the load is getting too hot without having to disassemble cartridges.)

As often as not, a rig will have at least decent velocity stats where you find a decent vertical node group at distance. By using the seating depth to fine tune the group shape, you then have enough to decide to stick with that recipe or abandon it. If you keep it, you explore the edges to know exactly how wide the node is before you go out of tune.

Good Luck and in for the range report.

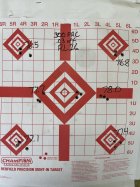

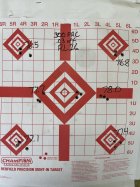

Picture of the groups. 3 shots on large diamond are factory. Point of aim on 77.7 and 78 are the tips of the diamond.

-

EFB6A007-FD80-4BC4-A954-6E7860FD20F8.jpeg

488.3 KB

· Views: 86

Picture of the groups. 3 shots on large diamond are factory. Point of aim on 77.7 and 78 are the tips of the diamond.

Since these are all jump of 30, you may still find that the seating depth is worth looking at too.

The advantage of being at distance, is it is much easier to interpret vertical nodes and group center movement. As much as folks want to see "flat spots" in the chrono data, they should be looking for clusters in the shotfall at distance. The groups in those vertical nodes can then be tuned with seating depth and you have a good first look at the gun/recipe potential. Bottom line is more focus on groups/shotfall, and using distance as a leverage to make interpreting results easier. YMMV

Please explain to us how this isn't a ladder test.

3 shots each charge shot at same point of aim, bullets colored for clarity.

View attachment 1349660

again in simple english

before the ladder was known it was

normal to shoot GROUPS of 3-5 shots in increasing powder charges.

it was and always will be SHOOTING GROUPS.

when the LADDER was made popular by long range mil shooters, it was called a LADDER, because LIKE A LADDER, there is only ONE step before going up to the next STEP. NO GROUPS, just single steps either on a real ladder or in a load ladder.

Chrieghton audette's ladder method...probably from the 50/60's

A series of 20 rounds was loaded in 0.2 grain pow-der increments and fired over a chronograph, starting with the least amount, starting with the least amount of powder and ending with the most."

just because a person calls something a ladder does not make it so.

done...do your own research

Not to start a debate about what is or isn't a ladder, or an Audette Ladder.... but just because there are three samples instead of one doesn't mean it isn't a ladder, that just means it has three samples.

In my past, we called an Audette Charge Ladder a test that went to distance in order to watch the shotfall, and many times that meant without a chronograph. That was to identify vertical nodes, and it could be one string or even several samples per charge step.

Like any small sample testing, we must be careful not to read too much into the samples since we know that there is an unknown dispersion for each one that is TBD.

Nothing wrong with the test, but it didn't sound like there were any group center locations or vertical data taken, which is a shame since the most critical data can often be found there.

not true, that is not an audette ladder. mislabelling something does not make it true

Creighton's test wasn't over a chronograph, it emphasized vertical shotfall.

In the DoD world, we did usually start charge level tests and call them ladders with a single sample string, but then still called them ladders even if we repeated them several times, which tends to begin to shed light on the repeatability of the nodes.

It was best to run them in single string fashion, but then we reversed the order on the way down and back up again to watch for barrel heating and fouling effects. Heavy weapons get hot just like small ones.

Other than being careful to watch for bias effects, there would have been no big harm in running them in groups at each step and letting a barrel cool. It would just take all day.

In today's world, any testing where charges or seating depths are incremented, have been called "ladders". Like you, I didn't like it when they started calling just about anything a ladder.

While I didn't like it, I was outnumbered long ago...

Personally I would go with a little slower powder like H1000.

What rifle/scope? Why 30 off with the Bergers?

Hired Gun Painting

Silver $$ Contributor

Number 3 sounds about right, I do 3 shot incremental charge tests every time I go to Deep Creek, most fellas just call them ladders.

View attachment 1349787

Ascending steps like this. Lol

A rose is a rose is a rose by any other name.

What rifle/scope? Why 30 off with the Bergers?

Rifle is a Defiance action/proof barrel with a Nightforce 5-25. The full story is a had 400 pieces of ADG virgin brass. When I got the brass I figured I would work up a load with the virgin brass knowing I would need to do it all over again once I had shot the brass. I don’t shoot that much so 400 rounds lasted me a year and a half. Plus I figured it would be a great learning opportunity to redevelop a load. With virgin brass, .03 off, 77gr, 2900 fps, the rifle shoots half minute and I’ve hit targets at a mile. The 1x fired brass was cleaned, annealed, FL sized with no expander ball, and mandrel sized. So here I am now. I appreciate everyone’s input and all of this information has helped my learning process.

Creighton's test wasn't over a chronograph, it emphasized vertical shotfall.

i do not know where you get your MISINFORMATION, but page 92 of PRECISION SHOOTING'S "RELOADING QUIDE" you will see a plot of 20 shots from a sample LADDER, where VELOCITIES FROM A CHRONGRAPH are plotted and the plateaus(nodes) are noted.

In the DoD world, we did usually start charge level tests and call them ladders with

isnt dod the same people that paid $300 for a HAMMER AND $500 FOR A TIOLET SEAT. i would not be using that life as a reference for the real world.

Hired Gun Painting

Silver $$ Contributor

Rifle is a Defiance action/proof barrel with a Nightforce 5-25. The full story is a had 400 pieces of ADG virgin brass. When I got the brass I figured I would work up a load with the virgin brass knowing I would need to do it all over again once I had shot the brass. I don’t shoot that much so 400 rounds lasted me a year and a half. Plus I figured it would be a great learning opportunity to redevelop a load. With virgin brass, .03 off, 77gr, 2900 fps, the rifle shoots half minute and I’ve hit targets at a mile. The 1x fired brass was cleaned, annealed, FL sized with no expander ball, and mandrel sized. So here I am now. I appreciate everyone’s input and all of this information has helped my learning process.

Have you run a seating depth test at all or did you start at .030 off and just stayed there?

I'd also test neck tension .002 above and below current setting in .001 increments after seating test.

Fine tune powder after all other testing is completed.

Looking at the graph provided and your targets I'd start tuning around 77.5 -77.6

I appreciate everyone’s input and all of this information has helped my learning process.

Same reason I joined here. I have gotten a lot of good advise and help here from the members

It's curious that your load using virgin brass was notably and consistently better than that same brass once-fired. Usually we expect to see a modest improvement as fired brass fire forms to the chamber.

The once-fired brass that you're now working with - is that the same lot of brass that you saw 1/2 MOA from previously?

Same lot of powder? Same lot of bullets?

You've got a solid body of experience with that load in that rifle - 400 rounds is a compelling statistical sample. Given that long experience, I'd be inclined to re-run your ladder. And I'd load enough rounds to do it twice (cleaning the bore between each 21-shot segment - I'm including three foulers). I would pay attention to velocity - because that gives you a proxy into what kinds of pressures you're running - but would mostly ignore ES until you're dialed back into a load that is starting to look interesting.

Have you confirmed the amount of shoulder bump you're getting when you FL size?

QuickLoad shows a preliminary print (preliminary because it's using all program defaults) of 2914 fps with the 215gr Berger Hybrid out of a 26" barrel, with 78.0/RL-26. So it's in the neighborhood of what you're seeing.

isnt dod the same people that paid $300 for a HAMMER AND $500 FOR A TIOLET SEAT. i would not be using that life as a reference for the real world.

The "$500 Hammer" was an instrument that contained a piezoelectric force sensor for modal analysis testing.

It would have cost anyone else $800, but the Gov caught a break. Leave it to some "wet behind the ears" politicians to distract the public with BS, while the real waste went un noticed right in front of them.

The "toilet seat for $300" was a $100 custom airplane seat that includes $200 worth of paperwork because we have to let all the government bureaucrats in Richmond participate.

But fear not, the Clinton Administration kicked all the standards bodies out of the DoD and forced them into the ASTM and SAE. Everybody knows that an international committee gives a S@#T about the DoD's problems and America's defense industry capabilities. Enjoy your "real world" as you watch the standards and quality of life go down the tubes. YMMV.