You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help please. 243 bolt click

- Thread starter walley2960

- Start date

AckleymanII

Gold $$ Contributor

LHSmith said:"A very good match chamber" ? .....for what? What does a tight chamber offer besides brass problems?CatShooter said:RCBS makes a small based sizing die:

This is not a "problem" or a bad set-up... it is the consequence of having a very good match chamber... and it is common.

"Classic example of the reamer/chamber being too tight at at the web.

Best fix is to take the barrel off and hone out the web area of the chamber."

Ok, what is the worth of a good match chamber, less expansion...

Now, it it expands less, that may equate to primer pockets staying tighter longer, less wobble of the factory brass in the chamber.

Nothing unusual about this issue at all.

Some great fixes are suggested.

That is pure silly!

I agree with honing out the base....even if the .45 die works, resizing will always require a 2-die set-up and the associated problems that come with it. If you load to starting load pressures only, you may be able to skip the extra base sizing to every other firing.

match chambers save the primer pockets and generally cause no issues, they are much easier on the brass.. I have seen match chambers cut for Lapua 6.5x284 destroy winchester brass. I have seen winchester match chambers you can't get Lapua brass into. Match is not just competition, but also matched to your brass and bullet choice. We always spec the reamer on tye brass we will use and have the throat cut for the bullet weight.

I wonder what reamer was used for this chamber?

I wonder what reamer was used for this chamber?

rcw3

Site $$ Sponsor

IMO - - Not enough info given by the original post for anyone to do anything other than guess at the situation. For starters, some info I would like to know:

1. What exactly is the load (i.e. not just make and type of powder but also the amount, what Berger 105 bullet, etc.)?

2. Barrel twist?

3. Make of brass used?

4. Are you FL sizing after each firing?

9x out of 10 that's a symptom of a hot load. If you drop the load that has to bolt click by 2 more grains, does it still do that?

1. What exactly is the load (i.e. not just make and type of powder but also the amount, what Berger 105 bullet, etc.)?

2. Barrel twist?

3. Make of brass used?

4. Are you FL sizing after each firing?

9x out of 10 that's a symptom of a hot load. If you drop the load that has to bolt click by 2 more grains, does it still do that?

I ordered the reamer from ptg. I spoke with Dave and asked that it be ground for Winchester brass and the Berger 105 hybrid.

I'm out of the lands about .010 and just above the neck shoulder junction with the bearing surface.

43 grains of h4350 may just be to hot. I ran a pressure test up to 45gr before and tight bolt started but that was a fresh barrel and new winchester brass.

To recap....

.243 winchester

Started with new winchester brass

43 gr h4350

105 berger hybrid

8 twist Krieger

I do full length size each time and adjust the die to set the shoulder back.

Velocity around 3165.

I intend to reduce the charge and start over with a small lot of new brass as I get the time. Also the small base die may come into play depending on the results there.

I'm out of the lands about .010 and just above the neck shoulder junction with the bearing surface.

43 grains of h4350 may just be to hot. I ran a pressure test up to 45gr before and tight bolt started but that was a fresh barrel and new winchester brass.

To recap....

.243 winchester

Started with new winchester brass

43 gr h4350

105 berger hybrid

8 twist Krieger

I do full length size each time and adjust the die to set the shoulder back.

Velocity around 3165.

I intend to reduce the charge and start over with a small lot of new brass as I get the time. Also the small base die may come into play depending on the results there.

swd

Silver $$ Contributor

You've found and exceeded the max pressure of your load combination in your rifle. Back the load down and the problem will go away. Opening up the chamber is going backwards, the brass will just expand even more and complicate the problem. Yes if you keep opening it up enough eventually the problem will go away but that's not fixing the actual problem. You can size the brass down if you want to but don't expect great brass life. I would guess that if you load the same case a few times in a row you'll find the primer pockets probably won't last long anyways.

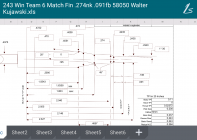

Well, after reviewing all the helpful replies I looked into the reamer. In hindsight I believe for my application I would have been better served by something more standardized. In my defense I didn't ask for the tight chamber (only free bore and neck dimensions) but lesson learned. The redding rep told me that I could try the small base .308 bushing die (they do not make one specifically for .243). While I'm waiting for the die to arrive I will try some lighter loads. I have included the reamer print as I thought it good info for those interested.

Thanks again for all the helpful replies.

Wally

Thanks again for all the helpful replies.

Wally

Attachments

Wally,,,your reamer drawing shows that the reamer is .001" too small at the .200 line,,,it should be .471 and the neck is .274 and most brass loads at .273-.274...that could cause pressure pronblems if your not turning the necks ( I use 42.2 gr of H-4350 and that is near max in my bbl ) ,,,reamers made small like that are more problems than they are worth,,,,Roger

I suspect the .470 at the .200 line is what is causing the "click" . I planned on truing the necks and using a bushing die so that I wouldn't "overwork" the brass in that area.

I have my doubts that a lower charge will help my cause long term, but will fire that small lot of brass repeatedly in the next day or two.

I hope the small base die sizes brass enough that it will work properly.

All in all though. I agree with those who stated "not worth the trouble".

I have my doubts that a lower charge will help my cause long term, but will fire that small lot of brass repeatedly in the next day or two.

I hope the small base die sizes brass enough that it will work properly.

All in all though. I agree with those who stated "not worth the trouble".

searcher

Gold $$ Contributor

Instead of a short-based die, how about a Harrel's Precision sizer die in .308 with our choice of Redding bushing? Send them a fired case for die match-up. Of course, that won't fix the underlying problem which is likely running too hot of a load. It might serve to 'fix' your brass and keep it there.

alf

Silver $$ Contributor

walley2960 said:I suspect the .470 at the .200 line is what is causing the "click" .

Well, I'll be a son-of-a-bitch, who da thought.....

forsyth793

Silver $$ Contributor

Run a couple of cases through a 30/06 full length die with the spindle removed, but lube them well. This might tell you if you are going in the right direction...

alf said:walley2960 said:I suspect the .470 at the .200 line is what is causing the "click" .

Well, I'll be a son-of-a-bitch, who da thought.....

Walley,

SAAMI minimum is .4714..... http://www.saami.org/pubresources/cc_drawings/Rifle/243%20Winchester.pdf

So, looks like you have the dreaded match reamer...bet you didn't ask for it. The first reamer I purchased from Dave Kiff was a so-called "match" reamer with cartridge dimensions less than SAAMI spec...caused me nothing but grief and I did not ask for something less than SAAMI. If I were you, I"d have a talk with Dave Kiff and tell him you did not specifically ask for a reamer with cartridge dimensions less than SAAMI and therefore he should provide you with a new reamer where the cartridge dimensions adhere to SAAMI. Bottom line is you can't expect 3rd party dies that are made to SAAMI specs to work with a chamber reamer that is below SAAMI specs. If the reamer maker did this without customer consent, then he should provide a replacement IMHO.

Erik Cortina

Team Lapua Brux Borden Captain

Reamer is too tight. Last reamer I ordered from PT&G had the same issue. Caused me a lot of problems and chased my tail for a long time.

If PT&G won't fix it, call JGS and have them re-grind it for you to proper dimensions.

If PT&G won't fix it, call JGS and have them re-grind it for you to proper dimensions.

CatShooter

Erik Cortina said:Reamer is too tight. Last reamer I ordered from PT&G had the same issue. Caused me a lot of problems and chased my tail for a long time.

If PT&G won't fix it, call JGS and have them re-grind it for you to proper dimensions.

If a reamer is too tight (too small), how do you re-grind it to make it bigger??

Erik Cortina

Team Lapua Brux Borden Captain

CatShooter said:Erik Cortina said:Reamer is too tight. Last reamer I ordered from PT&G had the same issue. Caused me a lot of problems and chased my tail for a long time.

If PT&G won't fix it, call JGS and have them re-grind it for you to proper dimensions.

If a reamer is too tight (too small), how do you re-grind it to make it bigger??

The reamer is a cone, if you "set it back", it will get bigger.

Update. In order to use the chamber as is. I am using the small base die that Cat Shooter recomended. I tried a redding .308 small base bushing die but the shoulder of the brass was moving more than I liked. It could have been the way I had it adjusted.

Anyway problem solved for now. I will definitely be getting the reamer reground for the next barrel.

Thank you to all that added input.

Anyway problem solved for now. I will definitely be getting the reamer reground for the next barrel.

Thank you to all that added input.

BoydAllen

Gold $$ Contributor

One more piece of information that may help someone: In my experience, Redding dies tend to be the largest at their bottom of any FL bushing die. RCBS makes perfectly serviceable bushing FL dies that are smaller in this area. Recently this solved a base of case sizing problem with a match type reamer. The difference was all that it took. Anymore, I am cautious about selecting any of the the Redding Bushing FL dies for any custom chamber that may be a little small.

Walley,

Thanks for posting this problem. Adding Catshooter's 45 ACP die idea to my reloading files.

The issue of brass not working properly in a chamber is something I have encountered with the 338 RCM, 300 RUM and a wildcat the 7mm/375 Ruger. The issue shows up with the first or sometimes the second firing. The web area is causing extra resistance during bolt lift. I believe the thicker brass has less springback. I also believe that the dies available are not sizing this area enough just as you encountered with your tighter match chamber.

With the above cases I do not believe the manufacturers are making allowances for the thicker brass, making a FL sizing die with the usual reduction of body taper. I tried several dies with the 338 RCM:

First Redding (the worst) then Hornady which was better but still not right. I send some brass to Whidden for a custom FL bushing die which was the best. BUT I still had some issues with twice fired brass.

THEN I found a thread where someone had created his own small base ring similar to the Catshooter's 45 ACP idea. I have a lathe. Using a carbide tool bit cut off neck and shoulder of a FL die. Then remove a significant amount of the base of the die. I want to tell you this makes some beautiful orange sparks till it cuts through the case hardening.... The end result is a tapered tube with enough range of adjustment for proper reduction of the web area which removed the issue entirely.

A un altered full length die will have to be used as the next step as the small base ring will lengthen the brass. I have made one of these SB rings for the 338 RCM, 300 RUM and the 7/375 and am very happy with the results.

I thought that this situation is so similar to your tight based chamber it was worth sharing.

Thanks for posting this problem. Adding Catshooter's 45 ACP die idea to my reloading files.

The issue of brass not working properly in a chamber is something I have encountered with the 338 RCM, 300 RUM and a wildcat the 7mm/375 Ruger. The issue shows up with the first or sometimes the second firing. The web area is causing extra resistance during bolt lift. I believe the thicker brass has less springback. I also believe that the dies available are not sizing this area enough just as you encountered with your tighter match chamber.

With the above cases I do not believe the manufacturers are making allowances for the thicker brass, making a FL sizing die with the usual reduction of body taper. I tried several dies with the 338 RCM:

First Redding (the worst) then Hornady which was better but still not right. I send some brass to Whidden for a custom FL bushing die which was the best. BUT I still had some issues with twice fired brass.

THEN I found a thread where someone had created his own small base ring similar to the Catshooter's 45 ACP idea. I have a lathe. Using a carbide tool bit cut off neck and shoulder of a FL die. Then remove a significant amount of the base of the die. I want to tell you this makes some beautiful orange sparks till it cuts through the case hardening.... The end result is a tapered tube with enough range of adjustment for proper reduction of the web area which removed the issue entirely.

A un altered full length die will have to be used as the next step as the small base ring will lengthen the brass. I have made one of these SB rings for the 338 RCM, 300 RUM and the 7/375 and am very happy with the results.

I thought that this situation is so similar to your tight based chamber it was worth sharing.

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.