Bump the shoulder back further than new brass?Bump the shoulder back .001 to .oo2 . Just my two cents Tommy Mc

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hard bolt lift mild load

- Thread starter PD Gohil

- Start date

timeout

Silver $$ Contributor

Very true but the OP says that he also has trouble closing the bolt. Like some others, I'm uncertain how the bolt closed after the brass has been properly full length sized with a .001" - .002" shoulder set back.Does your receiver's serial number begin with a "RR"? If so, you may have to get the bolt handle re-timed in order to get the proper primary extraction. It's a well known but correctable issue with the RR Remington's.

It could be that he's not sizing, I just considered his comments on hard extraction and he wasn't getting bolt swipe marks that I would associate with undersized reloads. The timing is an easy one to check and if it's not where it needs to be than no amount of sizing will help.Very true but the OP says that he also has trouble closing the bolt. Like some others, I'm uncertain how the bolt closed after the brass has been properly full length sized with a .001" - .002" shoulder set back.

If thats what it takes. New is not perfect all the time. Tommy Mc I had some NEW 220 Swift brass out of 100 37 had to bump the shoulder. I will not name the manufacturer.. Tommy McBump the shoulder back further than new brass?

RegionRat

Gold $$ Contributor

Yes, helps to get a better picture.Hold on... I somehow must have misspoke. I do not have any issue closing the bolt on a sized round. The only time I have trouble is closing the boat on a empty case that has already been fired before resizing. Hope that clears things up

By chance, have you checked the dimensions of your brass to find the boundary when it goes in easy versus when it doesn't?

I would break out the drawings and specs for the ammo/chamber and the micrometers and calipers and get down to brass tacks on inspecting the brass.

We are this deep into a 7 MAG discussion and I am a little surprised we haven't mentioned the body collet die or the diameter just above the belt?

It is a common problem in 7 Mag to need to body size the brass just above the belt after a few cycles.

In that case ,i don,t have a clue. Just stating what has happened to me. Good luck with the fix. Tommy McHold on... I somehow must have misspoke. I do not have any issue closing the bolt on a sized round. The only time I have trouble is closing the boat on a empty case that has already been fired before resizing. Hope that clears things up

RegionRat

Gold $$ Contributor

Do you have a micrometer? If so, take a reading to the nearest 1/10,000 just above the belt about 1/4" above the base on cases that are trouble, and ones that are not.

Is your case dimension at or below 0.5136 at that place?

Now check the diameter just below the shoulder at 1.97" above the base. Is it at or below 0.4928"?

Is your case dimension at or below 0.5136 at that place?

Now check the diameter just below the shoulder at 1.97" above the base. Is it at or below 0.4928"?

Sandstorm

Gold $$ Contributor

I think we call those Clikker's....The click when you open the bolt on a fired round.

or hard extraction..due to a miss-match between your dies and your chamber..

Is this brand new and fireforming..or have you sized these rounds.?

I may be mistaken if its band new brass.

or hard extraction..due to a miss-match between your dies and your chamber..

Is this brand new and fireforming..or have you sized these rounds.?

I may be mistaken if its band new brass.

So here's what I foundDo you have a micrometer? If so, take a reading to the nearest 1/10,000 just above the belt about 1/4" above the base on cases that are trouble, and ones that are not.

Is your case dimension at or below 0.5136 at that place?

Now check the diameter just below the shoulder at 1.97" above the base. Is it at or below 0.4928"?

New Norma cases

OAL 2.495

BELT .527

1/4 ABOVE THE BELT .506

@1.97" .489

1x fired norma brass that's sticky

OAL 2.496

BELT .528

1/4 ABOVE THE BELT .5105

@1.97" .4935

So tell me what that means.

RegionRat

Gold $$ Contributor

What we are doing is checking the brass against the specs.So here's what I found

New Norma cases

OAL 2.495

BELT .527

1/4 ABOVE THE BELT .506

@1.97" .489

1x fired norma brass that's sticky

OAL 2.496

BELT .528

1/4 ABOVE THE BELT .5105

@1.97" .4935

So tell me what that means.

Both the shoulder datum length and the diameters are important, and too often those diameters don't get discussed till someone has trouble.

That diameter at the body shoulder junction for the standard chamber is supposed to be 0.4928 and your brass is at 0.4935 The spec allows 0.4948 max, so you may get by.

We will now ask you to size that case and see where your dies put that diameter with the minimum sizing it takes to get the case back into the chamber.

The diameter just above the belt sounds wrong because I think you went too far up the case.

The measurement is supposed to be at " take a reading to the nearest 1/10,000 just above the belt about 1/4" above the base" .

So not 1/4" above the belt but above the base. The shoulder stop for the belt is at 0.220 - 0.227", so the 0.250" above the base is just above the belt, not 1/4 above the belt. Think of it being about about 27 mils above the belt. At that height, the chamber diameter is supposed to be 0.5136" to 0.5156" and the cartridge is supposed to be 0.5127"

The next question would be what that diameter looks like on your troublesome case.

Dies don't to a great job getting 7mm Mag back into shape just above the belt. We have a tool called a belted magnum collet die that might help, but right now we need to measure that case to see if the diameter is too big.

https://www.larrywillis.com/mainpage.html

Take that diameter just above the belt and then size the case just enough to get it to chamber and take readings again. Also lets see how much shoulder set back you have to use to get the shoulder diameter to work.

A belted mag "headspaces" on the belt the first cycle, but then we try not to set the shoulder back too much thereafter. The hope is that your chamber and dies will play well together when the shoulder is sized back, but that is dependent on those diameters we have been discussing as well as that shoulder length.

If the body-shoulder diameter looks good after the should is set back, then sometimes that lower diameter can be addressed with that collet die to get more brass cycles till the primer pocket lets go.

Have a look at page 44 in this SAAMI spec and you will see what I am asking you with a drawing.

https://saami.org/wp-content/upload...99.4-CFR-Approved-2015-12-14-Posting-Copy.pdf

timeout

Silver $$ Contributor

Excellent post!! Whenever I work up a new load I'm measuring case diameters. Also very important when firing new chamber jobs. I haven't had a tremendous amount of barrels chambered but I have had one that was cut with the diameter too large and one with the headspace set too long. Measure, Measure, Measure!What we are doing is checking the brass against the specs.

Both the shoulder datum length and the diameters are important, and too often those diameters don't get discussed till someone has trouble.

That diameter at the body shoulder junction for the standard chamber is supposed to be 0.4928 and your brass is at 0.4935 The spec allows 0.4948 max, so you may get by.

We will now ask you to size that case and see where your dies put that diameter with the minimum sizing it takes to get the case back into the chamber.

The diameter just above the belt sounds wrong because I think you went too far up the case.

The measurement is supposed to be at " take a reading to the nearest 1/10,000 just above the belt about 1/4" above the base" .

So not 1/4" above the belt but above the base. The shoulder stop for the belt is at 0.220 - 0.227", so the 0.250" above the base is just above the belt, not 1/4 above the belt. Think of it being about about 27 mils above the belt. At that height, the chamber diameter is supposed to be 0.5136" to 0.5156" and the cartridge is supposed to be 0.5127"

The next question would be what that diameter looks like on your troublesome case.

Dies don't to a great job getting 7mm Mag back into shape just above the belt. We have a tool called a belted magnum collet die that might help, but right now we need to measure that case to see if the diameter is too big.

https://www.larrywillis.com/mainpage.html

Take that diameter just above the belt and then size the case just enough to get it to chamber and take readings again. Also lets see how much shoulder set back you have to use to get the shoulder diameter to work.

A belted mag "headspaces" on the belt the first cycle, but then we try not to set the shoulder back too much thereafter. The hope is that your chamber and dies will play well together when the shoulder is sized back, but that is dependent on those diameters we have been discussing as well as that shoulder length.

If the body-shoulder diameter looks good after the should is set back, then sometimes that lower diameter can be addressed with that collet die to get more brass cycles till the primer pocket lets go.

Have a look at page 44 in this SAAMI spec and you will see what I am asking you with a drawing.

https://saami.org/wp-content/upload...99.4-CFR-Approved-2015-12-14-Posting-Copy.pdf

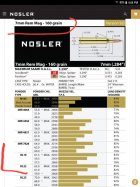

This is your maximum powder charge, for your rifle & components.Backed all the way down to 62 grains, I'm getting right at 2900 FPS, and just a bit of bolt stick

The bullet your using has a heavy thick jacket. This increases pressure when compared to other bullet designs, with thinner jackets.

The brass that was over pressure may need scrapped, or sized with the https://www.larrywillis.com/

Use Nosler data.

Last edited:

So finally an update on this whole situation. The main problem was a little bit of extra sizing lube left on the brass. I've settled into a load of 62.5 grains RL-22. It's averaging 2886. It's a touch slower than I'd like but next spring I will try different brass. Load is shooting 3/4 MOA at 100 and 300 yards. Very pleased with it. And contrary to others comments I have found the powder to be very stable temperature wise. From 76° to 28°, I only saw a 35 ft per second drop on velocity.

Attachments

Sold my Rem 700 mag many years ago. Don't have my reloading data anymore. I shot 154 gr Hornady RN bullets with 4831 or 4350. Forgot which one I got wallet groups with. Shot many rounds no pressure.7mm rem mag rem 700. 24" barrel.

Unknown Round count.

First load development for this rifle

New Norma brass

Fed 215M PRIMER

Nosler accubond 160

RL 22 powder

Book max is 65

.020 off the lands.

I spoke with WVLONGSHOT and he feels it's an issue with the Norma brass being softer.

I loaded up rounds from 62.5 to 65 in half grain incriments to see what this rifle liked. The first couple shots the bolt felt a touch sticky, after that it became very stuck. I did not shoot it past 63.5 grains. No bolt swipe, no flatten primers, no cratered primers. Backed all the way down to 62 grains, I'm getting right at 2900 FPS, and just a bit of bolt stick. I can't understand what's causing this.

Today was hot, upper 80s and I was in the full sun reloading at the range for this development. I'm wondering how much the sun was causing an issue. But still I don't think it should cause extraction problems.

The 62 and 1/2 grain load shot incredibly well sub moa 2936 fps and SD 5 , But it does no good if you can't work the bolt!

I'd appreciate any help thanks.

Another thing I noticed when firing a string of three, the last shot was always the hardest to lift and extract That's one reason why I'm thinking heat is an issue.

PGohil

WV

Similar threads

- Replies

- 19

- Views

- 2,676

- Replies

- 10

- Views

- 1,795

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.