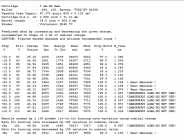

No signs of pressure leading up to this event. None... no flat primers, no marks on bottom of case, no sticky bolt. Then, "Boom!" Well, it wasn't like that either. Made the shot. Ejected the round and thought "wow" when I saw the case. It was the third group with increased powder. Increasing in increments of 0.3 grains. First round of that group. Packed it up and headed home.... Just don't know what sign I missed before this happened.

Speeds were increasing as well as the other "no sign" issues listed... until this shot. Speed decreased. Case ruined. I threw the other 6 cases in the trash too... just being safe.

Any idea on what I missed with over pressure signs?

ADDED:

7mm08 Tikka Stainless. Think it was the brass. I don't use RP for at least four years now. I'm not sure how that one got loaded... and I didn't notice it was RP until I posted this picture (can we all say "Blind as a Bat? LOL). Went back after posting this to see some other loads and RP used - 5 of them. Already disassembled... but I threw away 6 good brass earlier I'm sure. It kinda scared me as I have never had this happen before.

I was working a 120 TTSX with N140. 43.4, 43.7, 44.0 (case issue), 44.3 (did not shoot). If anyone can provide a quickload review before I try again it would be greatly appreciated.

and... the primer was pierced.

Speeds were increasing as well as the other "no sign" issues listed... until this shot. Speed decreased. Case ruined. I threw the other 6 cases in the trash too... just being safe.

Any idea on what I missed with over pressure signs?

ADDED:

7mm08 Tikka Stainless. Think it was the brass. I don't use RP for at least four years now. I'm not sure how that one got loaded... and I didn't notice it was RP until I posted this picture (can we all say "Blind as a Bat? LOL). Went back after posting this to see some other loads and RP used - 5 of them. Already disassembled... but I threw away 6 good brass earlier I'm sure. It kinda scared me as I have never had this happen before.

I was working a 120 TTSX with N140. 43.4, 43.7, 44.0 (case issue), 44.3 (did not shoot). If anyone can provide a quickload review before I try again it would be greatly appreciated.

and... the primer was pierced.

Attachments

Last edited: