Chambering 6 identical 6.5 PRCs this week I noticed the surface finish in the throat and leade seemed worse than usual. I only recently started chambering at 190 and 300 Rpm. Both are better than the slower speeds I had been using it seemed to me but I really wish my lathe had something between the two. I tried a plethora of things in the final few passes between the 6 barrels, evaluating the throat after each time and I just can’t seem to get a very smooth cut on the lead angle. I tried to polish the throat on one of the passes before I was at final depth with some flitz back and forth with a tight patch and all it did was make the jagged throat easier to see the stair steps in it.

For reference these were cut with a Manson 6.5 prc reamer that only had 9 chambers cut on the first barrel and 15 chambers on the last. I drill within .100 of the shoulder to minimize how much material the throat has to cut and pre-bore within .025 of shoulder diameter. Once the shoulder starts to cut I drop RPM to 190 as if left at 300 the barrel work hardens as the feed rate is decreased. I wouldn’t think that the reamer is dull after that many chambers and its had no ill abuse unless 300 rpm will destroy them that fast. The one thing that seemed to help I did on the last barrel was get out a second reamer that is identical and brand new and cut the last .030 with it. This was a Brux and I ran no bushing on the reamer, the other 5 were bartlein and I did use a bushing. The Brux looks better but still not near as smooth a finish as I’ve seen on some of my previous work or others videos I’ve seen and it was a brand spanking new reamer. Am I just too zoomed in and worrying about too much (I really don’t think so) or is there a secret to getting a mirror smooth finish on the throat and leade?

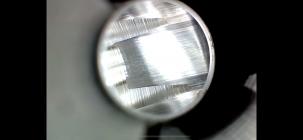

I can’t figure out how to share a video so I just took a picture of the videos I have. First picture is of the original reamer with the throat polished with flitz, second is just a reamer finish at 190 rpm same reamer, the last is the Brux with the brand new reamer used for the last .030 at 190 RPM.

For reference these were cut with a Manson 6.5 prc reamer that only had 9 chambers cut on the first barrel and 15 chambers on the last. I drill within .100 of the shoulder to minimize how much material the throat has to cut and pre-bore within .025 of shoulder diameter. Once the shoulder starts to cut I drop RPM to 190 as if left at 300 the barrel work hardens as the feed rate is decreased. I wouldn’t think that the reamer is dull after that many chambers and its had no ill abuse unless 300 rpm will destroy them that fast. The one thing that seemed to help I did on the last barrel was get out a second reamer that is identical and brand new and cut the last .030 with it. This was a Brux and I ran no bushing on the reamer, the other 5 were bartlein and I did use a bushing. The Brux looks better but still not near as smooth a finish as I’ve seen on some of my previous work or others videos I’ve seen and it was a brand spanking new reamer. Am I just too zoomed in and worrying about too much (I really don’t think so) or is there a secret to getting a mirror smooth finish on the throat and leade?

I can’t figure out how to share a video so I just took a picture of the videos I have. First picture is of the original reamer with the throat polished with flitz, second is just a reamer finish at 190 rpm same reamer, the last is the Brux with the brand new reamer used for the last .030 at 190 RPM.

Attachments

Last edited: