DngBat7

Silver $$ Contributor

Reloading question.

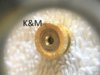

1. Do I have to trim length of brass before I can debut the flash hole? I know the cone on the flash hole debur tool sits on the neck of the brass. I am assuming if it’s not trimmed, it won’t be even surface at the top of the neck???? This is not new brass I am talking about. It is once fired factory hornady ammo

2. At what point do I anneal? Is it necessary? And what is a budget annealing machine???

Thanks again for all the help I have been receiving with all my questions

1. Do I have to trim length of brass before I can debut the flash hole? I know the cone on the flash hole debur tool sits on the neck of the brass. I am assuming if it’s not trimmed, it won’t be even surface at the top of the neck???? This is not new brass I am talking about. It is once fired factory hornady ammo

2. At what point do I anneal? Is it necessary? And what is a budget annealing machine???

Thanks again for all the help I have been receiving with all my questions