What's your opinion on sizing without the expander. To me as long as my necks aren't dinged up it sure seems to be easier on the brass and sizing is much smoother. I use a Lee universal de capping die to knock out the primers on an old worn out partner press. Is there a benefit to or not to be using it?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

expander button

- Thread starter Paddyd

- Start date

Dusty Stevens

Shiner

Most do not use the expander on bushing sized cases

I have not been using the expander balls, but I noticed that some of my new brass needs it before my first use because the necks are around -.003 to -004” compared to final size, so I’m using the ball to open up the necks to -.001” to -.002”. I’m not using the expander ball after that except for any case necks that I dinged up.

Basically it’s what @243winxb said, but you won’t normally need it after the first firing because the cases expand during firing once the bullet is out of the way.

Basically it’s what @243winxb said, but you won’t normally need it after the first firing because the cases expand during firing once the bullet is out of the way.

B23

Gold $$ Contributor

Most do not use the expander on bushing sized cases

Correct. With bushing dies, unless the button has a smaller OD than what the necks are being sized to, it defeats the purpose of using a bushing die so I always remove them. But, on standard FL sizing dies, sometimes, if you don't leave the button in you'll end up with a lot more neck tension than you want. With my 7mm Blaser Mag the only dies that were available, without going custom, was a Redding standard two die set with a FL sizing die and if I don't leave the button on the decapping stem I end up with way to much neck tension. I'm thinking about getting a .284/7mm KM mandrel set for that particular gun though.

The Redding bushing die FAQ tells you to use their expander that came with the bushing die if the neck thickness varies .002 or more. It also tells you to use a bushing approximately .002 smaller in diameter so the expander pushes the irregularities to the outside of the neck.

With one twist of the wrist the Redding neck thickness gauge below will tell you the quality and uniformity of your brass.

With one twist of the wrist the Redding neck thickness gauge below will tell you the quality and uniformity of your brass.

I use the expander, l don't neck turn my brass . Without neck turning most brass at the neck is thicker in some areas . When sizing without the expander your causing the uneven OD to transfer to the inner diameter causing a high runout , using the expander the inside diameter is in line with the sized case and your neck tension isn't as tight.

47WillysGuy

Gold $$ Contributor

I do not use the expander button. The button increases runout on my cases.

I use neck turned cases which removes the thicker sides of the necks. A Lee Collet Die(LCD) reduces the diameter of the neck and then mandrel increases case neck diameter about 0.001” under bullet diameter.

Average runout of 10 loads is 0.0015”.

Interference fit of seated bullet to case neck is 0.001”. This fit is my competition standard, not hunting.

My dial indicator is probably my most used precision measuring tool.

Then test to see which is better.

I use neck turned cases which removes the thicker sides of the necks. A Lee Collet Die(LCD) reduces the diameter of the neck and then mandrel increases case neck diameter about 0.001” under bullet diameter.

Average runout of 10 loads is 0.0015”.

Interference fit of seated bullet to case neck is 0.001”. This fit is my competition standard, not hunting.

My dial indicator is probably my most used precision measuring tool.

Then test to see which is better.

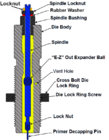

Below my Redding .243 full length die equipped with a Forster high mounted floating expander that greatly reduces neck runout vs the longer Redding expander. Why drag the longer Redding expander through the case neck that pulls much more on the neck. The high mounted Forster expander enters the case neck when it is held and centered in the neck of the die.

In my opinion with off the shelf factory rifles that allow the neck to expand far more than a custom chambered rifles you are better off using the expander. Bushing dies work best with tight neck chambers and neck turned brass. Neck turning on a factory rifle just allows the neck to expand more that has to be reduced when sizing the neck.

Below the Forster benchrest full length die, with its high mounted floating expander.

Guess what die with its expander has less neck runout than a Redding bushing die.

In my opinion with off the shelf factory rifles that allow the neck to expand far more than a custom chambered rifles you are better off using the expander. Bushing dies work best with tight neck chambers and neck turned brass. Neck turning on a factory rifle just allows the neck to expand more that has to be reduced when sizing the neck.

Below the Forster benchrest full length die, with its high mounted floating expander.

Guess what die with its expander has less neck runout than a Redding bushing die.

Last edited:

47WillysGuy

If your neck turning your brass , different ball game , your trueing the OD in that situation there's nothing wrong with removing the expander ball , to be honest I probably still would use the ball or some kind of expander to size the ID or the bullet would act as the expander , if not using bushing dies the neck tension may be too tight . Case neck thickness varies in different brands so without neck turning the neck tension will vary , the expander works better in those situations . I lube the inside of the necks with a Q tip very little resistance as the ball expands the neck . If your not neck turning your brass use the expander .

If your neck turning your brass , different ball game , your trueing the OD in that situation there's nothing wrong with removing the expander ball , to be honest I probably still would use the ball or some kind of expander to size the ID or the bullet would act as the expander , if not using bushing dies the neck tension may be too tight . Case neck thickness varies in different brands so without neck turning the neck tension will vary , the expander works better in those situations . I lube the inside of the necks with a Q tip very little resistance as the ball expands the neck . If your not neck turning your brass use the expander .

Uncle Ed

Setting up the die properly is important , I leave alittle wiggle room for the expander shaft and ball so it can self center. Went through the Redding bushing dies found the original old standard RCBS Full Size Sizing Die work best , with .001- .002 no more or less case headspace .

Setting up the die properly is important , I leave alittle wiggle room for the expander shaft and ball so it can self center. Went through the Redding bushing dies found the original old standard RCBS Full Size Sizing Die work best , with .001- .002 no more or less case headspace .

Uncle Ed

Setting up the die properly is important , I leave alittle wiggle room for the expander shaft and ball so it can self center. Went through the Redding bushing dies found the original old standard RCBS Full Size Sizing Die work best , with .001- .002 no more or less case headspace .

Below on the right the Forster expander and spindle assembly is a direct replacement for RCBS dies.

Again the Forster expander enters the case neck when it is held and centered in the neck of the die. Meaning the expander does not pull the case neck off center and induce neck runout.

NOTE, some RCBS dies will allow you to raise the expander as high as a Forster expander because the spindle is threaded lower on the shaft. And all you need to do is add a rubber o-ring under the lock nut and allow the expander to float. The RCBS expander on the left is raised as high as it will move and will not function like the higher Forster expander.

The use of an expander ball is not necessarily bad. I use a Forster full length resizing die. I had the inside of the neck area honed to reduce the constriction. The die reduces the neck .003" under the finished size and the ball reforms this leaving a .001" interference fit. It's also important to polish the ball and use lube. With the Forster, you can raise the ball closer to the shoulder. I bottom out a case and then raise the shaft and ball until I feel it touch. Then turn it back in 1/2 to 1 turn making sure it doesn't lockup in the die. This way most of the case neck is still in the neck portion of the die when the ball starts to pull through. Also the Forster shaft and ball due to loose threads and a rubber washer will float sideways a little to self align instead of pulling the necks out of alignment. I have tested this and the ball does not effect runout at all. It's probably best to not use the expander in a cheap die like a Lee.

I pop my primers first with a universal decapper , I wet tumble with SS Pins . The decapping pin is removed from the expander post , makes adjusting post height with expander simple . I do sandwich washers between a rubber o ring under lock nut to give me the self centering . Works well for me .

It's probably best to not use the expander in a cheap die like a Lee.

Actually the Lee locking collet holds and centers the expander in the die and the expander section is higher than most manufactures expanders. Meaning there is a bigger chance of locking the expander down off center in a RCBS or Redding die than with a Lee die.

Hmmm. Expanders are bad? When you use a bushing you transfer all the irregularities to the inside of the case so they are against the bullet. An expander transfers all those irregularities to the outside of the case leaving a smoother surface for bullet seating. I forget who makes them now but you can get expanders in .001 and .0005” increments. You can also polish one the right size.

When I started using an expander with my 6 BRA bushing die, my seating pressure became much more consistent and very smooth as measured by a 21st Century Hydro seater. Does it make a difference in groups at 600 and 1000 yds? I honestly don’t know. I have been shooting smaller groups but that could be better tuning, though consistent seating pressure is an important part of long range tuning.

When I started using an expander with my 6 BRA bushing die, my seating pressure became much more consistent and very smooth as measured by a 21st Century Hydro seater. Does it make a difference in groups at 600 and 1000 yds? I honestly don’t know. I have been shooting smaller groups but that could be better tuning, though consistent seating pressure is an important part of long range tuning.

In general-

Measure the case necks outside diameter before and after seating a bullet. If neck has expands .0015" to .002" after seating, this is ok.

If necks expand more then .004" after seating, you need an expander.

Don't understand. Expanding with the expander adds tension. It's the movement of the brass not when it's done. Expanding 2 thou with an expander then then expanding 2 thou with the bullet cold works the brass the same amount as expanding the neck 4 thou with a bullet. Tension is from the total movement of the brass not when it's done.

Similar threads

- Replies

- 25

- Views

- 5,773

- Replies

- 41

- Views

- 5,201

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.