Shooting when I can

Silver $$ Contributor

Hello guys

I am in need of some advice , I'll be the first to say I am not all that savy on which brand of machinery to buy when it comes to anything past your basic house hold hand tools

I am on the quest to speed up my neck turning process. And pondered that a drill press would speed up the process.

So I am looking for a

1. drill press under 300$ little to no runout on the chuck

2. XY cross slide vice

3. Is No.2 really needed or can I get away with a normal vice

Bonus question anyone have plans for a home made annealer?

Team Lapua Brux Borden Captain

Mini lathe is the best I have tried. I can turn 100 pcs of brass per hour with ease.

HF has them for $399.00 if you use their 20% off coupon.

Eric I was just thinking what Erik posted. Harbor Freight and be sure to use the coupons and get the other coupon to get the flashlight or battery tester FREE with any purchase!!! 8)

Team Lapua Brux Borden Captain

I will do a video soon on the mini lathe for my YouTube channel.

Shooting when I can

Silver $$ Contributor

Thanks Erik for the post I guess I'll start working on that. And learning is the mini lathe from HF worth it. I only ask because if I start to get good I am going to start working on the scrap barrels to start chambering my own stuff.

That's what I honestly think is going to happen.

ALSO congrats on the F-OPEN win

Team Lapua Brux Borden Captain

eric32 said:

Thanks Erik for the post I guess I'll start working on that. And learning is the mini lathe from HF worth it. I only ask because if I start to get good I am going to start working on the scrap barrels to start chambering my own stuff.

That's what I honestly think is going to happen.

ALSO congrats on the F-OPEN win

Thank you.

You can do small projects with the mini lathe but it's hard to get good accuracy with it. It's too small do any kind of barrel work. Mine is strictly for brass prep.

Shooting when I can

Silver $$ Contributor

Well then I look forward to your video

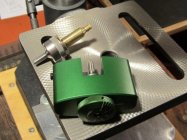

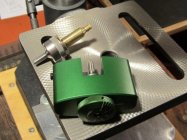

eric32: Although I still use the hand held method of outside neck turning, (Sinclair NT-4000), I sometimes have a large number of 6ppc to turn, and do use my drill press. It's a $60 one from Harbor Freight and I must have lucked out because there is no wobble when the case holder is turning in the chuck. Pics attached.

-

Drill press neck turning 001.JPG

46.9 KB

· Views: 291

-

Drill press neck turning 002.JPG

30.3 KB

· Views: 351

-

Drill press neck turning 003.JPG

29.6 KB

· Views: 302

Shooting when I can

Silver $$ Contributor

Fdshuster: at what speed are you setting the press at and what lube are you using? Also have you giving thought to a vice to hold the turner on and just use the handle of the press to move the case up and down onto the mandrel.

I have turned many, many thousands of cases with a drill press. The issue with a drill press is that most of them go way to fast in RPM's!!! I can't stress the fact enough that RPM's is a killer when it comes to making or breaking how well your operation will turn out. You want to get down as close to 100 rpms as possible, and with most of the drill presses, 270-320 is bare minimum.

So, I shopped around and found a Harbor Freight that would go to 170 RPM's and this was a long time ago, a floor model.

Now, there is a better way, and that is a variable speed half inch drill, shop the pawn shops. You have got to have the variable speed and the speed on the drill is adjusted by a screw in the trigger. Set your favorite speed with a piece of Gorilla Duct Tape. I hold the neck turner in the jaws of the drill, the piece of brass in the Sinclair holder, they get done licked split with very little run out if any.

I think that you are going to drive yourself crazy trying to find a drill press, floor model with low rpm's for $300 or less, $500 will get you there and look for sales.

Just for giggles and grins, ebay item shows a great example of a variable speed drill with the speed control in the trigger:

http://www.ebay.com/itm/BOSCH-1-2-CORDED-VARIABLE-SPEED-HAMMER-DRILL-/331480038227?pt=LH_DefaultDomain_0&hash=item4d2dbffb53

and another:

eBay item number:

191320540584

Most of the variable speed drills have a speed control that is in how far you depress the trigger, this is NOT the kind you want!!! Some of the 1/2" drills say they are variable speed, when they really are a two or three speed depending on how far you depress the trigger.

3/8" variable speed drills are too fast...don't even go there!

Good luck with your project!

eric32: At the lowest speed my drill press will operate, 620 rpm. A little CLP Breakfree on the turning mandrel. Yes, I will start to get a buildup of heat, but then just take a short break.

Have not done that many to require a vice to hold the case. Holding the body of the Sinclair turner works fine for me. If I only have 20 or 30 to do I still hold them with the Sinclair cross T handle. More than that and arthritis in the hands begins to be a problem, and that's when I'll use the drill press.

I expected to get a lot of wobble from the chuck, but they must have made a mistake and made a good one, for a change. The Sinclair case holders work fine.

Shooting when I can

Silver $$ Contributor

thanks guys for all the options and stuff to think about.

Ackleyman: pm replied

Fdhuster: what kinda of runout number are you getting with your turned necks w/ the high rpms?

Greg: Too slight to identify. Case neck walls are uniform around the whole circumference, using my Mitutoyo tubing mic.

Once fired, the majority straighten out, loaded round runout is .001" maximum. The occassional one that's more than .002" is written off and marked as a defective case from the time it was drawn.

Shooting when I can

Silver $$ Contributor

Thank you very much after Erik puts his video out I will make a decision on the drill press vs the mini lathe

ON the 1/2" drill, lay the drill on the bench on it's side. I am right handed. I press the trigger with my left hand while feeding the case on the mandrel with my right hand. When you get in the groove, you can do 6 per minute, at least.

The best lube is the Lee Sizing wax that comes in the tooth paste tube, nothing even compares. The Wax works good as a bullet lube, and lube for making bullets also, cut 50/50 with water in the microwave(don't let it boil).

First I drink the coffee, then I do the things.

Gold $$ Contributor

ackleyman II said:

When you get in the groove, you can do 6 per minute, at least

Are you saying you can turn 6 necks per minute?

I took Eric's advice and bought a mini lathe 7 x 10". It is well made and I am having a lot of fun making Hornady modified cases with it.

Good shooting,

Gene

Shooting when I can

Silver $$ Contributor

Gene66 said:

I took Eric's advice and bought a mini lathe 7 x 10". It is well made and I am having a lot of fun making Hornady modified cases with it.

Good shooting,

Gene

What brand did you get ? What tools did you buy with it? How much precision are you getting with the mini lathe?

Bruce Baselj

Gold $$ Contributor

I use an electric drill plugged into a router speed control. Just lock the trigger on full speed & just dial down the speed with the router control. Router control can be had on Ebay for around $20.

Cant believe nobody has mentioned the neck turning lathe setup from 21st Century? Much more compact than an actual mini lathe or drill press and speed can be controlled with your finger when using a cordless drill. Comes with everything you need except arbors and expanding mandrels. Price is $249

http://www.21stcenturyshooting.com/site/177699638b82447dbe3cbd3cb3a800bd/default?url=http%3A%2F%2Fwww.21stcenturyshooting.com%2F17-338_Cal_Neck_Turning_Lat.php#3034