Clock them and see if the Federal loads are faster?So far, all the measurements of the rounds appear to be in spec. Just an interesting occurrence, I think, but would still like to know why. I have some of those bullets being hand loaded into Hornady brass , so that may tell me a lot as well.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Difference In Effort To Open And Close Bolt; Federal vs. Hornady Factory Loads.

- Thread starter Turkeytider

- Start date

Indeed they are according to my chronograph. Then again, the box MV for the Federals is higher than the Hornady or AAC.Clock them and see if the Federal loads are faster?

Can you hear of feel the powder shake when you shake the cartridge? Could be compressed load in thee Federal.Indeed they are according to my chronograph. Then again, the box MV for the Federals is higher than the Hornady or AAC.

I had the same problem when shooting Federal Gold Match 175 grain 308. About 1 or 2 per box would chamber very hard, had to really press on the bolt to get it to close. After shooting a few boxes the ones hard to chamber would hit the target about 3 MOA high. Measured the brass OAL and found the problem rounds were 2.018 to 2.020. The maximum length should be 2.015. After trimming the brass back to 2.010 and reloading the problem went away.

For those kind enough to reply and had suggestions, it was indeed the Federal cartridge cases with the slightly wider neck at the head of the cartridge. Had some of the Berger 140 Hybrid Target bullets hand loaded into Hornady brass. Bolt closes and opens smooth as silk. Thanks everyone.Welp, I may have ( I think probably ) found the cause for the “ snugness “ of the Federal cartridges as compared to the Hornady and AAC cartridges, resulting in the tightness when operating the bolt. At the head of the cartridges, the necks have a different diameter. The Federals measure 0.41 “ while the Hornady and AAC measure 0.40” . Not a lot of difference and both within spec. according to my Lyman ammo checker. That’s the ONLY measurement difference I’ve been able to determine as far as the brass is concerned.

Interestingly, at least for me as a neophyte rifle shooter, I wonder if the tighter fit would result in somewhat higher pressure (? ) . If so, would that be reflected in higher muzzle velocity?

47WillysGuy

Gold $$ Contributor

I noticed the 0.010 difference, also. Probably is 0.001 is actual difference..010" difference in a loaded rounds outside neck diameter seems wrong? As does your measurement?

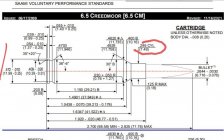

View attachment 1688873

That 0.295 on the drawing is my fired case neck dimension. SAAMI chamber dimension for the neck is 0.296.

My loaded case dimension is runs 0.287 -0.288, but true cut the necks.

Interesting!

Well, the “ neck “ ( not even sure if that’s the correct term ) to which I’m referring is up at the head of the cartridge case where the primer is. It’s an indentation between the flat area where the head stamp and primer is and where the head joins the body of the cartridge..010" difference in a loaded rounds outside neck diameter seems wrong? As does your measurement?

View attachment 1688873

That’s the .200 line of the case that many refer to.Well, the “ neck “ ( not even sure if that’s the correct term ) to which I’m referring is up at the head of the cartridge case where the primer is. It’s an indentation between the flat area where the head stamp and primer is and where the head joins the body of the cartridge

Thank you , sir! Good to learn something everyday!That’s the .200 line of the case that many refer to.

Similar threads

- Replies

- 30

- Views

- 9,801

- Replies

- 2

- Views

- 1,237

- Replies

- 20

- Views

- 9,983

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.