You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Did he figure it out?

- Thread starter Nightraider

- Start date

farmerjohn

Gold $$ Contributor

Thanks Jerry for the update. Let us know if y'all figure it out I'm curious as hell. Might be a teachable moment and learn something new....

John

John

carlsbad

Lions don't lose sleep over the opinions of sheep.

OK. I'll be seeing him on Saturday and I'll ask him for a barrel to bring home and examine.

I have found out this: His 223 barrels are 6.5 twist and his is shooting 90s.

His 308 barrels are more normal twist at 10.

Here is his cleaning procedure. Note the "oil in barrel" related to another popular thread lately:

1

Wet patch of Butch’s boreshine, normal loop tip

Use boreguide

2

At least one dry patch

Use Parker jag

3

Repeat several times based on dirt

2 to 3 times normally

4

Spray M Pro 7 in chamber and clean with nylon brush

1-2 times

5

Wet patch with Kroil and swab barrel and chamber

Leave in gun and fire next match with oil in barrel

6

Dissaemble bolt and clean with M Pro

--Jerry

I have found out this: His 223 barrels are 6.5 twist and his is shooting 90s.

His 308 barrels are more normal twist at 10.

Here is his cleaning procedure. Note the "oil in barrel" related to another popular thread lately:

1

Wet patch of Butch’s boreshine, normal loop tip

Use boreguide

2

At least one dry patch

Use Parker jag

3

Repeat several times based on dirt

2 to 3 times normally

4

Spray M Pro 7 in chamber and clean with nylon brush

1-2 times

5

Wet patch with Kroil and swab barrel and chamber

Leave in gun and fire next match with oil in barrel

6

Dissaemble bolt and clean with M Pro

--Jerry

Dusty Stevens

Shiner

No brush and a loop jag? Thats a barrel full of carbon abrasive every shot

AckleymanII

Gold $$ Contributor

I would think that he had made a mistake in his methodology in measurement to the lands. He would have to be cleaning with coarse valve grinding compound to erode the throat to the amount that he has stated.

carlsbad

Lions don't lose sleep over the opinions of sheep.

I would think that he had made a mistake in his methodology in measurement to the lands. He would have to be cleaning with coarse valve grinding compound to erode the throat to the amount that he has stated.

That's my thought. I'll be measuring his lands carefully.

farmerjohn

Gold $$ Contributor

Maybe I'm missing it, but if he leaves oil in the chamber as well as the barrel he's gonna have problems there also. but I expect that fast twist and long bullet and measuring process is going to be the problem.....OK. I'll be seeing him on Saturday and I'll ask him for a barrel to bring home and examine.

I have found out this: His 223 barrels are 6.5 twist and his is shooting 90s.

His 308 barrels are more normal twist at 10.

Here is his cleaning procedure. Note the "oil in barrel" related to another popular thread lately:

1

Wet patch of Butch’s boreshine, normal loop tip

Use boreguide

2

At least one dry patch

Use Parker jag

3

Repeat several times based on dirt

2 to 3 times normally

4

Spray M Pro 7 in chamber and clean with nylon brush

1-2 times

5

Wet patch with Kroil and swab barrel and chamber

Leave in gun and fire next match with oil in barrel

6

Dissaemble bolt and clean with M Pro

--Jerry

paperpuncher

Gold $$ Contributor

Is he using a less common throat configuration than the 1*30. Sometimes these will exhibit more rapid throat wear, but not likely at the rate being reported here. Perhaps a visit to Alex Wheelers site and review the info regarding finding the lands might help out. Sometimes getting a good baseline can be problematic

Chuck Wells

Silver $$ Contributor

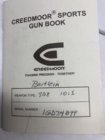

This is a real problem. Had a 300 reduced Palma match today and fired total of 95 rounds with erosion of 0.030. Attach is my barrel book. Total rounds fired is 373 with total throat erosion of 0.113. Measurements are using a Hornady comparator with same case and same bullet. Normally at least 5 readings taken, drop high and low then average. Readings are generally within 0.004. May not be accurate, but these are repeatable. These are loaded with 43.2 grains of H4895. Have similar behavior with Varget at 43.5 grains. Accuracy if this gun is about 1.5 MOA. This barrel has never shot as well as the original barrel nor the other two barrel that eroded very fast.

I am getting similar results on my 223. I gave my 223 to Jerry S today to look with a borescope. I have been fighting this problem for over 18 months with both guns. I must be doing something wrong in loading or cleaning.

Also attached is document describing the barrels and their life. Will have to send that later. Is on my one drive.

I am getting similar results on my 223. I gave my 223 to Jerry S today to look with a borescope. I have been fighting this problem for over 18 months with both guns. I must be doing something wrong in loading or cleaning.

Also attached is document describing the barrels and their life. Will have to send that later. Is on my one drive.

Attachments

Dusty Stevens

Shiner

I think we’re going to find a faulty cleaning method here. No powder/bullet combo possible can do that

Alex Wheeler

Site $$ Sponsor

I was asked my thoughts on this by a manufacture that has scoped the barrels. They really are burning out like he says. Im not sure any cleaning methods could cause anything like this. Its very strange. At this point I would be running some powder through a mesh trying to find the abrasive that some how got in there. A .223 should not have .400 throat wear unless its a machine gun.

farmerjohn

Gold $$ Contributor

Powder was my first thought, I would have a sample analyzed by an independent lab, probably won't cost that much and then eliminate that.....I was asked my thoughts on this by a manufacture that has scoped the barrels. They really are burning out like he says. Im not sure any cleaning methods could cause anything like this. Its very strange. At this point I would be running some powder through a mesh trying to find the abrasive that some how got in there. A .223 should not have .400 throat wear unless its a machine gun.

Dusty Stevens

Shiner

Didnt he try another powder? Surely he cant be the only guy in the country to get a jug of powder with sand in it and others have bought from that lot by now

Alex Wheeler

Site $$ Sponsor

Is he using a less common throat configuration than the 1*30. Sometimes these will exhibit more rapid throat wear, but not likely at the rate being reported here. Perhaps a visit to Alex Wheelers site and review the info regarding finding the lands might help out. Sometimes getting a good baseline can be problematic

Different throat angles dont seem to wear at a much different rate in my experience, surprisingly.

Just a thought, if your going to check the powders for contaminants then I would also check the cleaning products for contaminants. If the barrel metal is good, the powder is found to be clean and bullets are eliminated as the source then you are left with three possibilities. Damage via human action, mechanical (tools) or cleaning compounds. I realize I not saying anything new here I’m just thinking aloud.

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.