I have been playing with the idea of creating a wildcat, this is where I am at;

1. My goals:

A. To be able to use the wildcat in a HS precision PHR currently chambered for the 300WSM that I will re-barrel.

B. I would like to set up for the 7mm 168gr VLD class of bullets, and I would like them to fit into my magazine with room to play with my seating depth.

C. I would like a cartridge that will give velocities similar to a 280Rem, with a body shape that mimics the 6mmBR,maybe some of the cartridge accuracy and efficiency will transfer to my design)

2. My design idea:

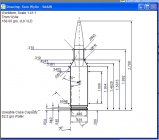

A.I have taken the 300wsm necked it down to 7mm and shortened it by about 1/4" and lengthened the neck, I have also changed the shoulder angle to 30 degrees.,see attached cartridge drawing)

B. The drawing was made using data from quick design and quick load, the resulting cartrige would have about 69.8 grains of water to the casemouth, about 62gr usable with the bullet seated to the indicated depth.,this depth will leave me about .080 room in my magazine to chase the lands for throat wear)

C. Max load should be able to produce approx 2900fps in a 24" barrel based on quickload data.,this will be a hunting rifle).

My questions:

1. How hard will it be to form the brass from 300WSM brass?

2. Do you foresee any problems that I have overlooked?

If you have any input or idea's it would be greatly appreciated.

My next step will be to get a reamer drawing to send Redding for die quotes.

Thanks for any input you have.

Ben

1. My goals:

A. To be able to use the wildcat in a HS precision PHR currently chambered for the 300WSM that I will re-barrel.

B. I would like to set up for the 7mm 168gr VLD class of bullets, and I would like them to fit into my magazine with room to play with my seating depth.

C. I would like a cartridge that will give velocities similar to a 280Rem, with a body shape that mimics the 6mmBR,maybe some of the cartridge accuracy and efficiency will transfer to my design)

2. My design idea:

A.I have taken the 300wsm necked it down to 7mm and shortened it by about 1/4" and lengthened the neck, I have also changed the shoulder angle to 30 degrees.,see attached cartridge drawing)

B. The drawing was made using data from quick design and quick load, the resulting cartrige would have about 69.8 grains of water to the casemouth, about 62gr usable with the bullet seated to the indicated depth.,this depth will leave me about .080 room in my magazine to chase the lands for throat wear)

C. Max load should be able to produce approx 2900fps in a 24" barrel based on quickload data.,this will be a hunting rifle).

My questions:

1. How hard will it be to form the brass from 300WSM brass?

2. Do you foresee any problems that I have overlooked?

If you have any input or idea's it would be greatly appreciated.

My next step will be to get a reamer drawing to send Redding for die quotes.

Thanks for any input you have.

Ben